Electro-optic crystal thin film for electro-optic modulator, preparation method and electronic components

An electro-optic modulator and electro-optic crystal technology, which is applied in optical components, optical waveguides, instruments, etc., can solve problems affecting the performance of electronic devices and damage to film layers, and achieve the goal of preventing optical signals from leaking to the substrate layer and having a small thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

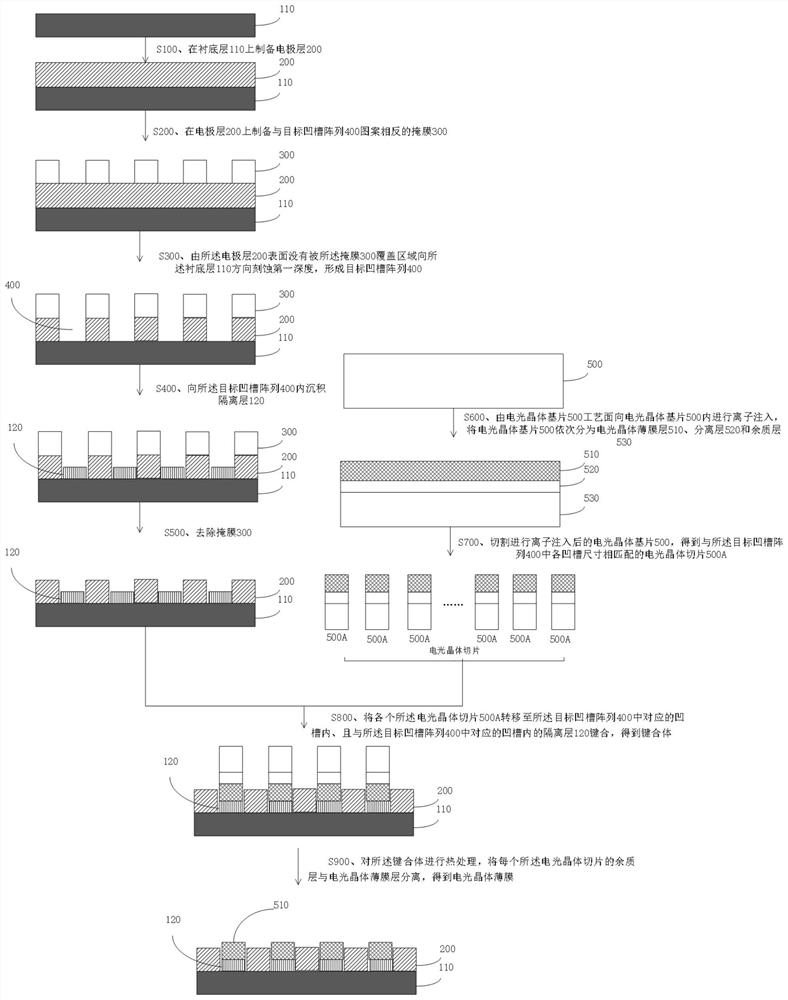

[0036] In step 100, an electrode layer 200 is prepared on the substrate layer 110.

[0037] The substrate layer 110 may be a single-layer substrate or a composite substrate, which is not limited in this application. Substrate layer of this application

[0038] The electrode layer 200 should be selected from metal materials with good electrical conductivity, such as copper (Cu), gold (Au), titanium (Ti), platinum

[0040] Further, the thickness of the Au layer is greater than the thickness of the Cr layer. Since the Au layer mainly functions as an electrode

[0041] The present application does not limit the method for preparing the electrode layer 200, for example: using a magnetron sputtering method, on a silicon wafer

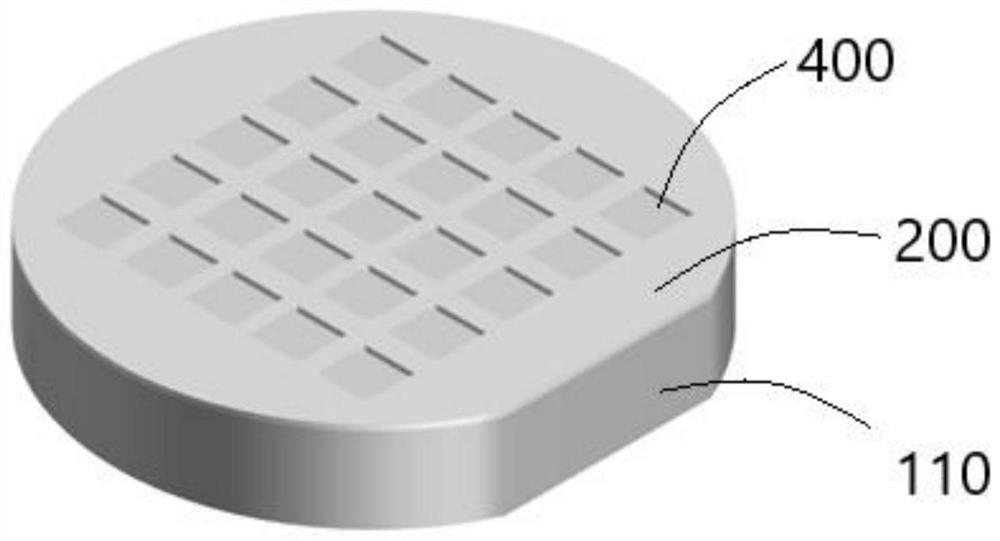

[0042] In step 200, a mask 300 having a pattern opposite to that of the target groove array 400 is prepared on the electrode layer 200.

[0045] The embodiment of the present application does not limit the method for preparing the mask 300 on the electrode layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com