Driving-type shot blasting machine

A technology of shot blasting machine and frame, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc. It can solve the problems that the shot blasting head cannot move left and right, has poor flexibility, and cannot be adjusted, and achieves large blasting. The effect of pill working width, high working efficiency and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

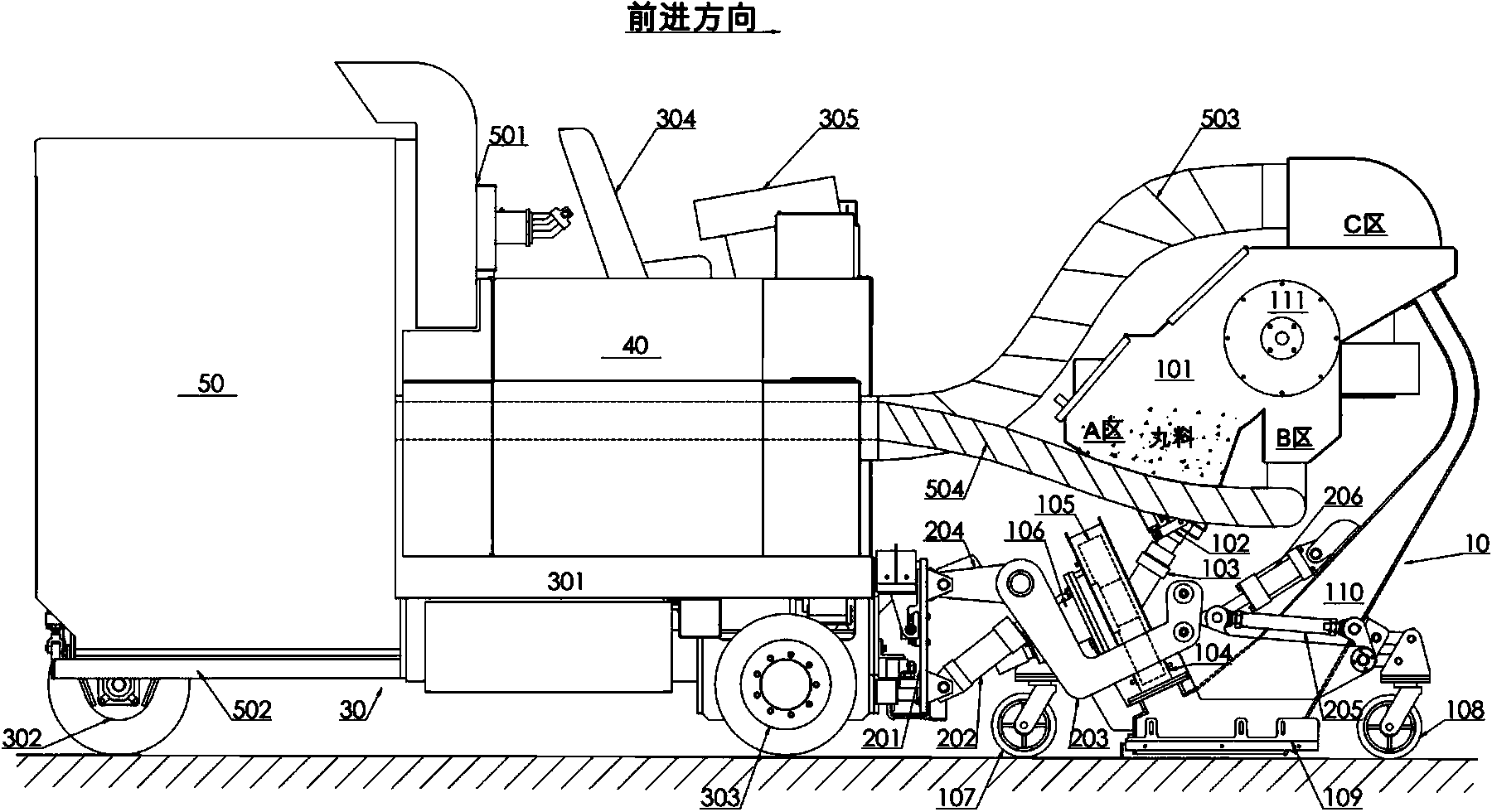

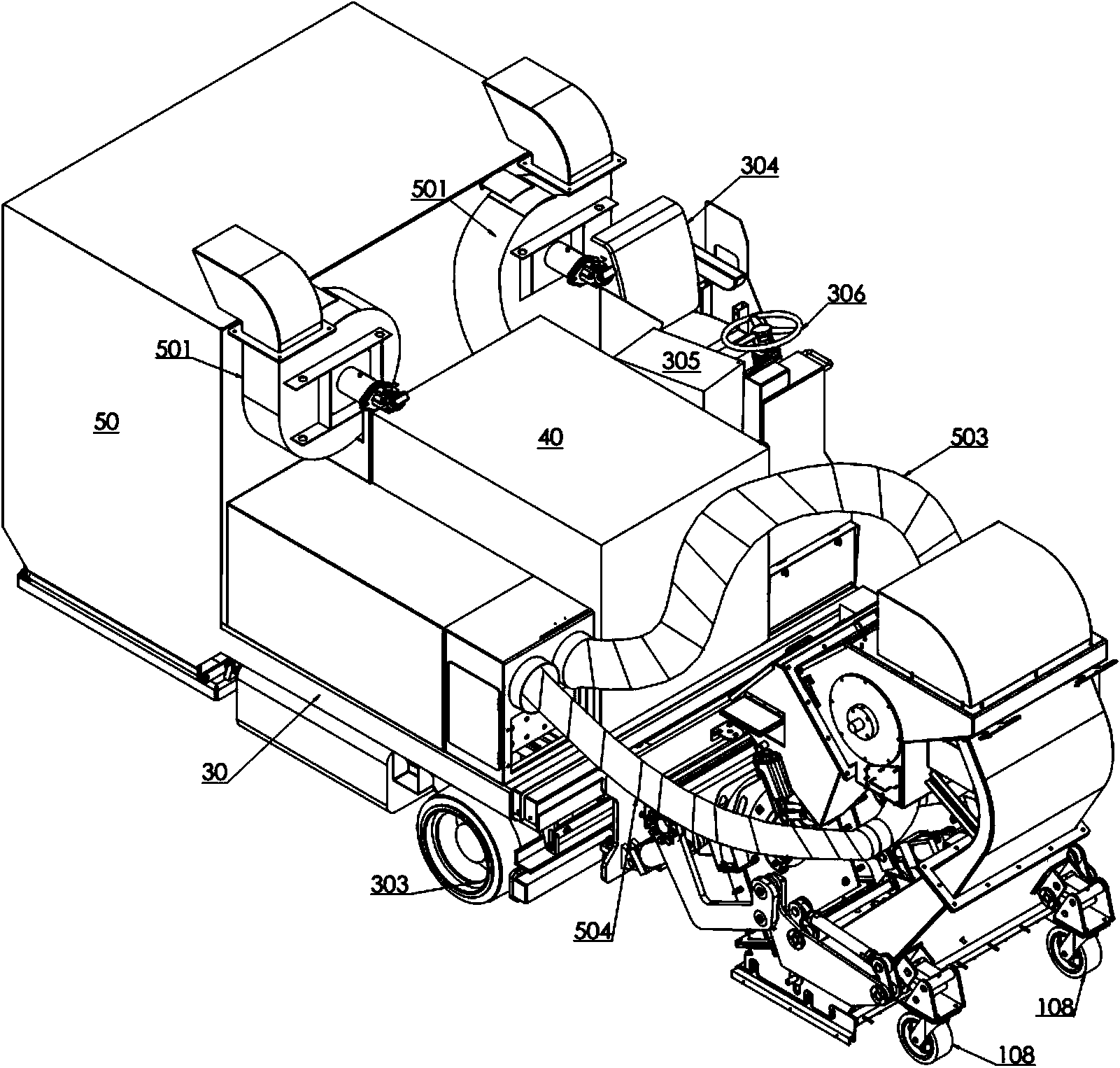

[0036] A driving type shot blasting machine, its structure is as follows: Figure 1-2 As shown, it can be used for the treatment of related surfaces, such as shot blasting of floors, ship decks, airport runways, highways, bridges, tunnels, etc. The equipment described in the present invention can use hard granular pellets as the operation treatment medium, such as steel shot, steel grit and the like. The ride-on shot blasting machine is composed of a shot blasting unit 10 , a lifting and side shifting unit 20 , a frame unit 30 , a power unit 40 and a dust removal unit 50 . Among them, the shot blasting unit 10 is located at the front of the equipment, and is connected to the frame 30 through the lifting and side shifting frame unit 20. The power unit 40 is installed on the frame 30, and the dust removal unit 50 is arranged at the rear of the equipment and is also installed on the frame. 30 on. The lifting and side shifting frame unit 20 controls the position of the shot blas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com