Glass sand-blasting machine used for glass surface processing

A glass surface and sandblasting machine technology, which is applied to used abrasive processing devices, abrasive jetting machine tools, spray guns, etc., can solve the problems of long processing cycle, high operator skill requirements, complex process, etc., to improve the stability performance. , Sandblasting is convenient and simple, and the operation is safe and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

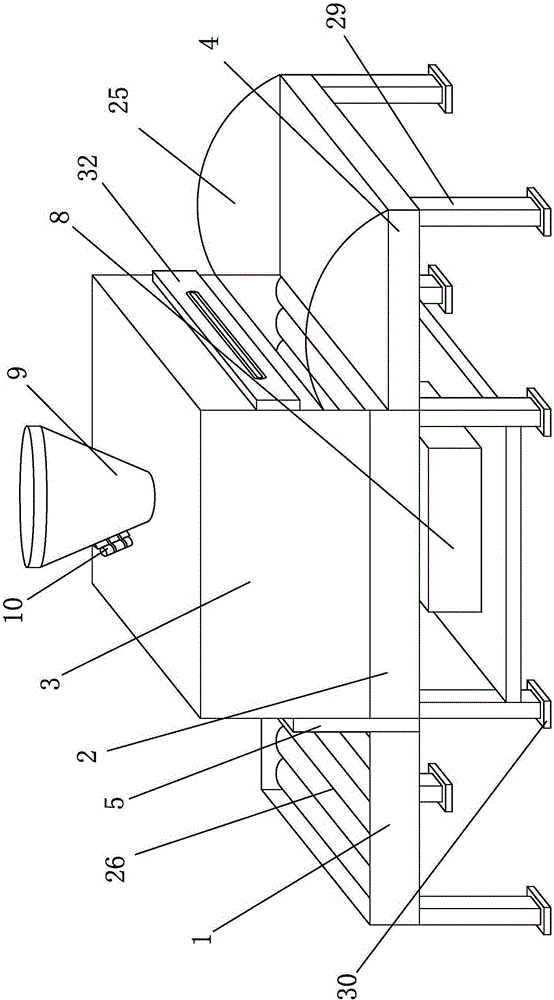

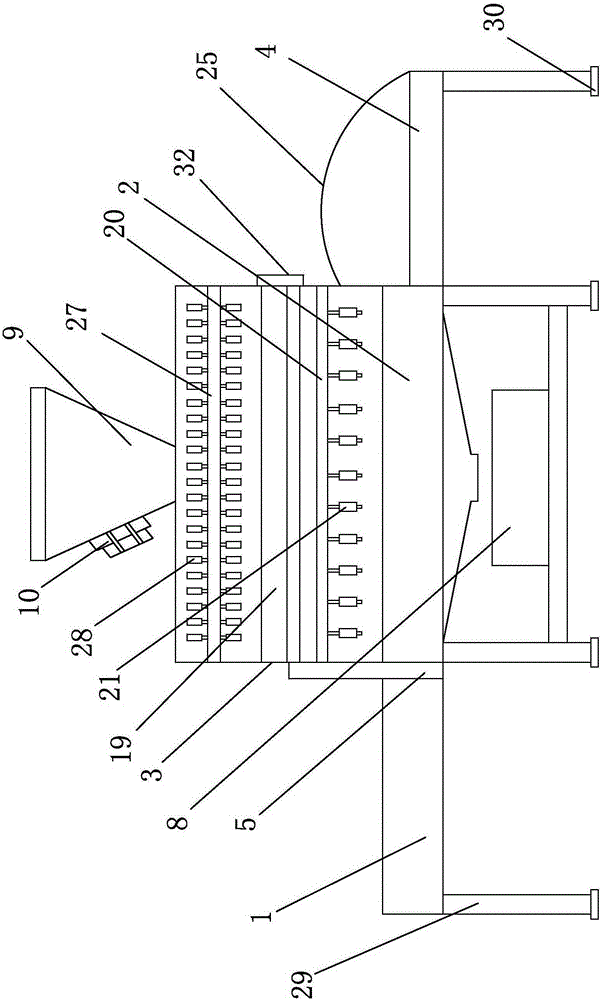

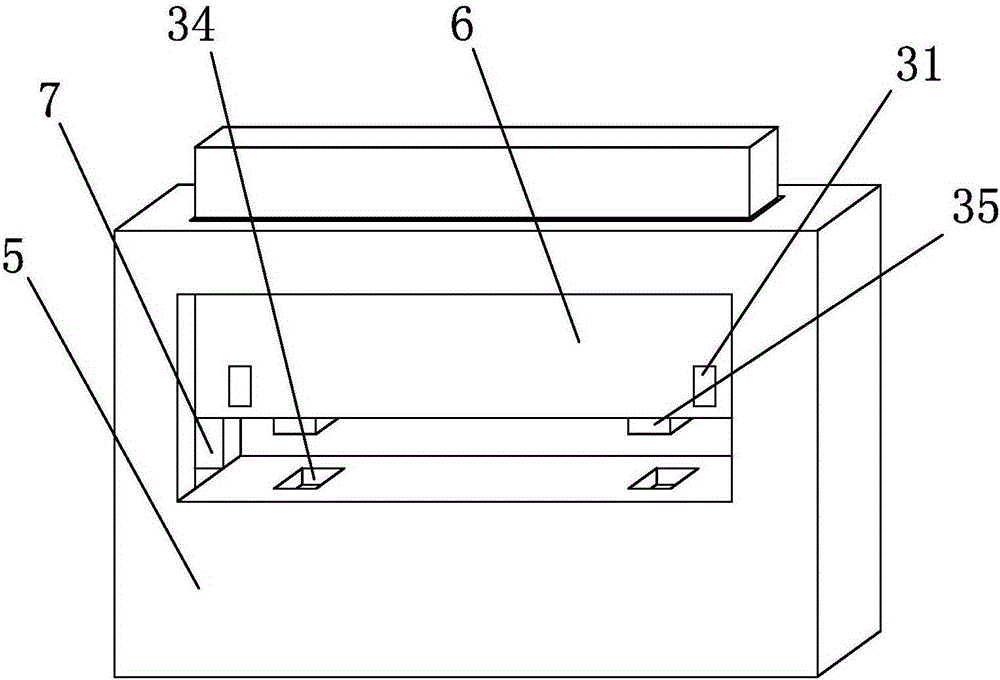

[0030] Such as Figure 1 to Figure 6 As shown, it is a glass sandblasting machine for glass surface treatment according to the present invention, which includes a discharge platform 1, a sandblasting platform 2, a sandblasting chamber 3 and a discharge platform 4, and the discharge platform 1 and the sandblasting platform 2 are Both are equipped with material conveying rollers 26. The design of material conveying rollers 26 can make the sandblasting of glass more convenient and simple. Compared with the previous design, the operator only needs to place the glass on the discharge table 1 and press the start button That is, there is no need to manually move the glass, which not only improves the production efficiency, but also the quality of the glass after sandblasting is higher. , the bottom of the support column 29 is provided with a shock absorber 30, the design of the shock absorber 30 improves the stability of the glass blasting machine, reduces the noise pollution generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com