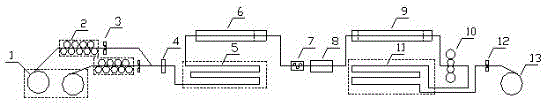

Continuous annealing acid pickling system and method for hot rolling stainless steel composite steel belt

A composite steel and stainless steel technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as inability to realize continuous annealing and pickling functions, complicated proportioning of pickling passivation solution, and unguaranteed plate shape. , to achieve the effect of stable product performance and surface quality, obvious pickling effect and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

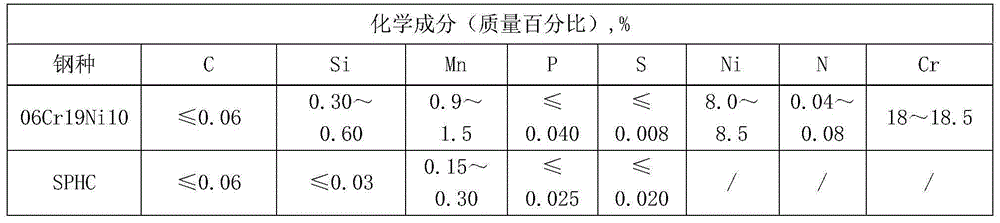

[0036] Specifications (thickness*width) of steel strip to be annealed and pickled: 2.95×1240mm.

[0037] Anneal and pickle as follows:

[0038] Welding: The steel coils are uncoiled, straightened and cut and then sent to a MIG argon arc welding machine for welding, with a welding current of 135A and a welding speed of 600mm / min.

[0039] Annealing temperature: P3 plate temperature 1057 ℃, TV value 130.

[0040] Mechanical descaling: the reduction of the scale breaker, the bending roller is 70mm, the straightening roller is 75mm, and the shot blasting machine has 2 sets of 16 blasting heads, and the blasting head current is 100A.

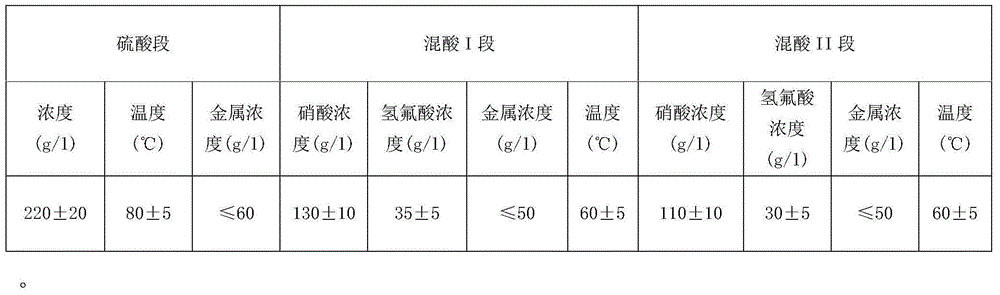

[0041] Pickling temperature and concentration control: sulfuric acid section: concentration 237.1 g / l, metal concentration 46.2 g / l, temperature 81 °C; mixed acid section I: nitric acid concentration 132.5 g / l, hydrofluoric acid concentration 38.3 g / l, metal concentration 46.5 g / l, temperature 57.9 °C; mixed acid stage II: nitric acid concentration...

Embodiment 2

[0044] Specification of pickling strip to be annealed (thickness * width): 3.0×1240mm.

[0045] Anneal and pickle as follows:

[0046] Welding: The steel coils are uncoiled, straightened and cut and then sent to a MIG argon arc welding machine for welding, with a welding current of 150A and a welding speed of 550mm / min.

[0047] Annealing temperature: P3 plate temperature 1051 ℃, TV value 125.

[0048] Mechanical descaling: the reduction of the scale breaker, the bending roller is 75mm, the straightening roller is 80mm, the shot blasting machine has 2 sets of 16 blasting heads, and the blasting head current is 100A.

[0049] Sulfuric acid section: concentration 218.4g / l, metal concentration 47.5 g / l, temperature 80℃; Mixed acid section I: nitric acid concentration 130.8 g / l, hydrofluoric acid concentration 36.1g / l, metal concentration 47.9 g / l, temperature 58.0℃ ; Mixed acid stage II: nitric acid concentration 109.7 g / l, hydrofluoric acid concentration 30.4 g / l, metal concen...

Embodiment 3

[0052] Specification of pickling strip to be annealed (thickness*width): 3.75×1240mm.

[0053]Anneal and pickle as follows:

[0054] Welding: The steel coils are uncoiled, straightened and cut and then sent to a MIG argon arc welding machine for welding with a welding current of 175A and a welding speed of 500mm / min.

[0055] Annealing temperature: P3 plate temperature 1048 ℃, TV value 112.

[0056] Mechanical descaling: the reduction of the scale breaker, the bending roller is 80mm, the straightening roller is 85mm, the shot blasting machine has 2 sets of 16 blasting heads, and the blasting head current is 95A.

[0057] Sulfuric acid section: concentration 210.5g / l, metal concentration 45.1 g / l, temperature 80℃; Mixed acid section I: nitric acid concentration 122.6 g / l, hydrofluoric acid concentration 33.5 g / l, metal concentration 41.9 g / l, temperature 57.5℃ ; Mixed acid stage II: nitric acid concentration 109.8 g / l, hydrofluoric acid concentration 28.4 g / l, metal concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com