Shot-blasting machine

A technology of shot blasting device and lifting device, which is applied to the processing device of used abrasives, abrasive jetting machine tools, abrasives, etc., and can solve the problems of saving space and other disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

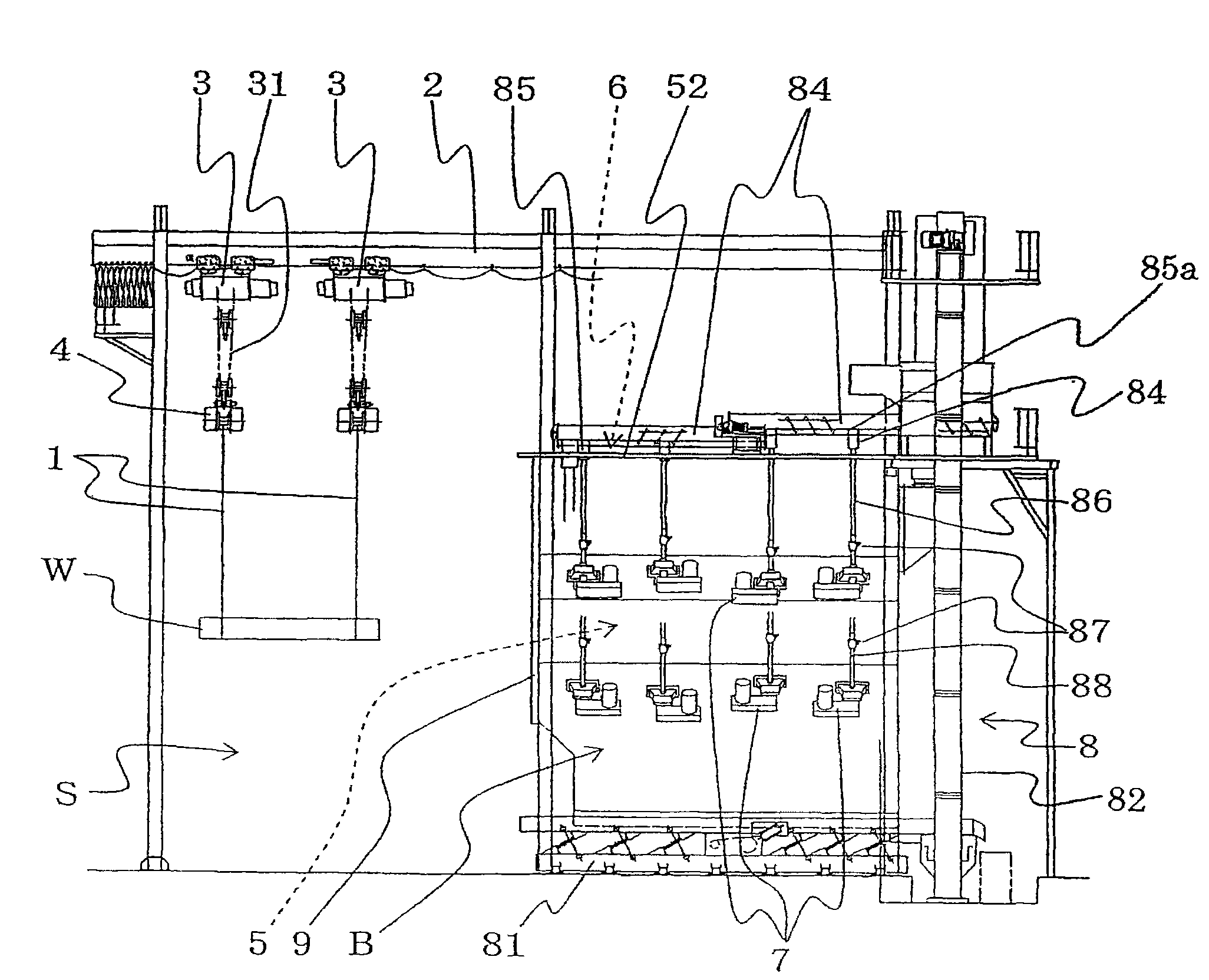

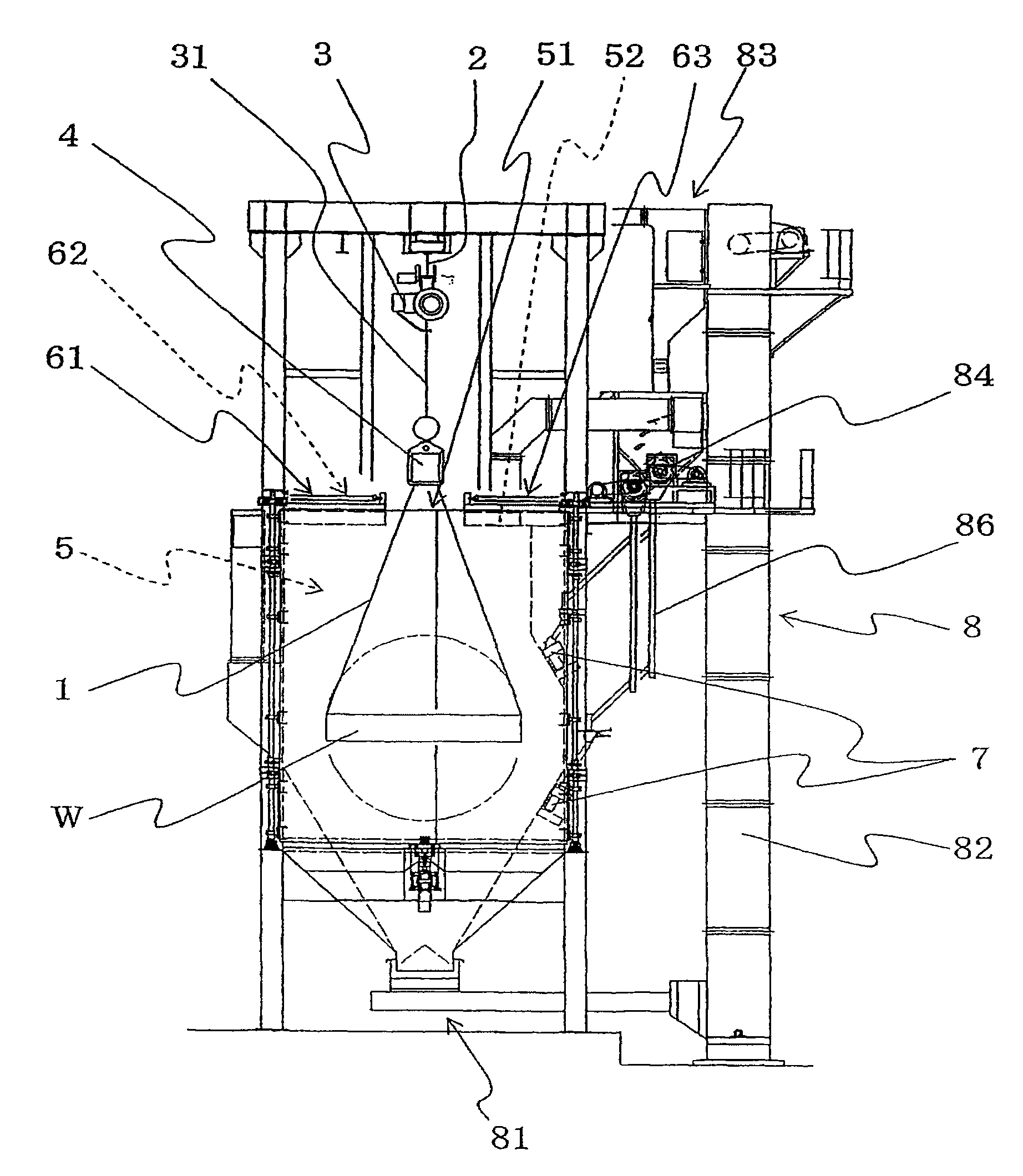

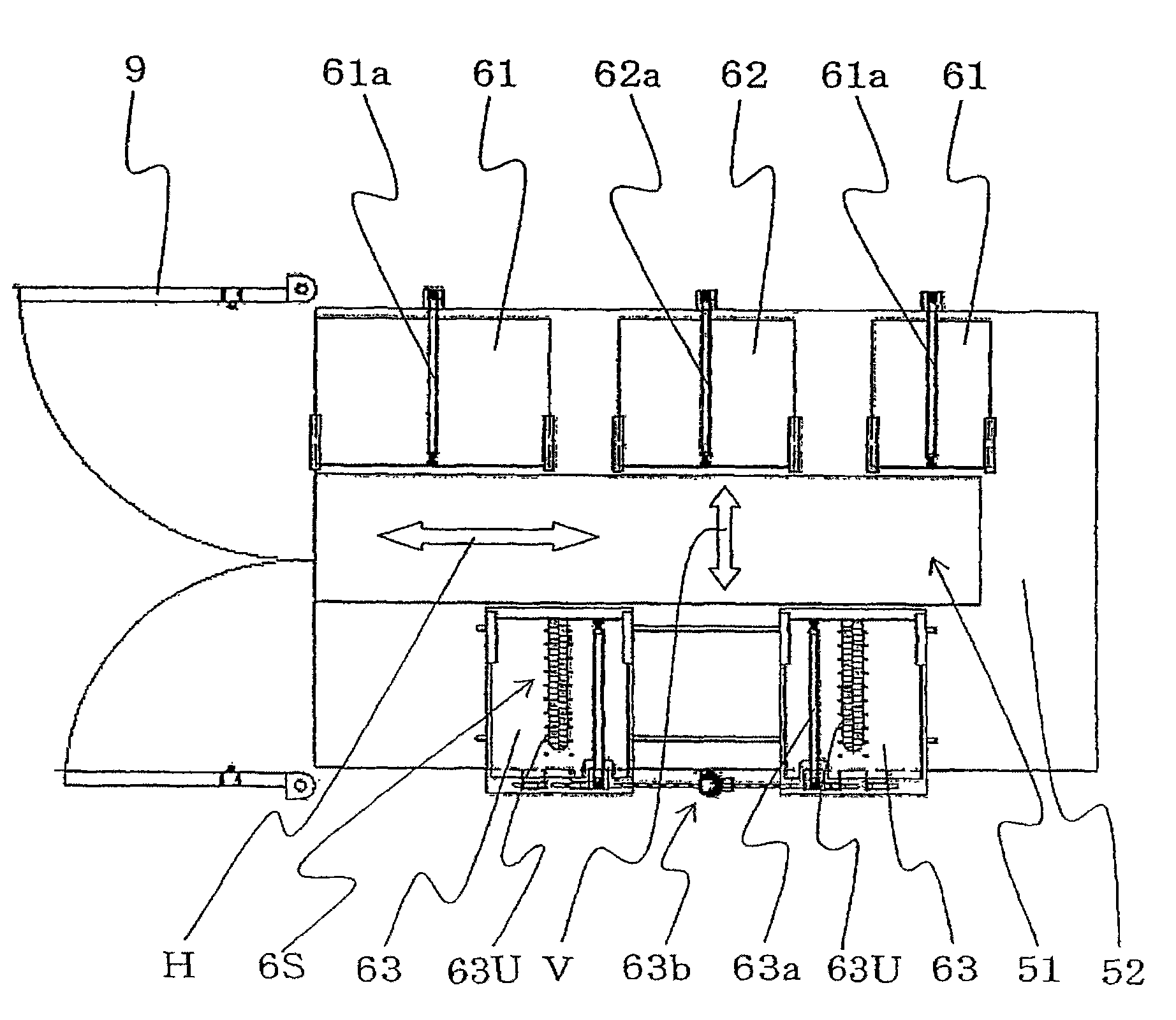

[0018] Such as figure 1 , figure 2 with image 3 A horizontal rail 2 is provided on the upper part of the shot blasting device in the illustrated embodiment, and the rail 2 can bear the load caused by the suspension of the workpiece W. The track 2 extends from above a working area S to above an enclosure B, which is the area where the workpiece W is wound on and released from a chain sling 1, the The enclosure B defines a projection chamber 5.

[0019] The rail 2 is provided with two elevators 3 (vertical moving devices) that can move along the rail 2, and the elevator 3 can also be moved vertically by, for example, a steel wire 31. Suspended on each steel wire 31 of each elevator 3 is a reversing machine 4. The reversing machine 4 includes a chain sling 1 which is an annular member formed by a chain connected end to end, and a sending mechanism for sending out the chain sling 31. The length of the chain sling 1 is such that at least part of the circumference of the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com