Steam blasting machine

A technology of steam explosion machine and warehouse explosion, applied in chemical instruments and methods, methods of chemically changing substances by using atmospheric pressure, chemical/physical processes, etc., can solve the problem of limited opening speed of high-pressure valves, reduced energy density, and increased equipment Cost and other issues, to achieve the effect of reducing multi-pillar resistance, speeding up the bursting speed, and uniform heating and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

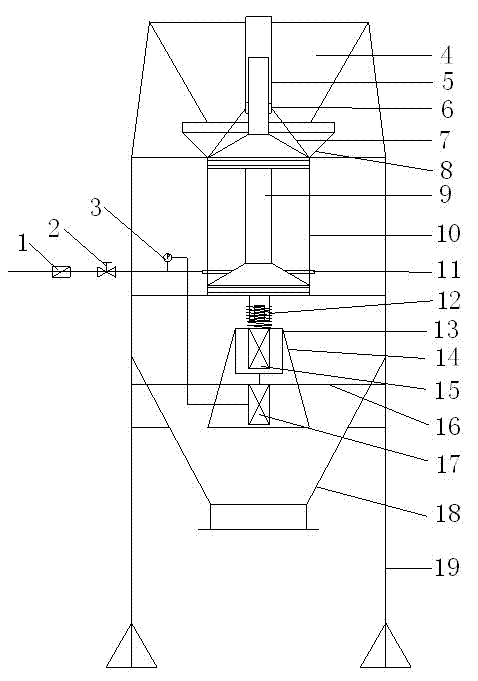

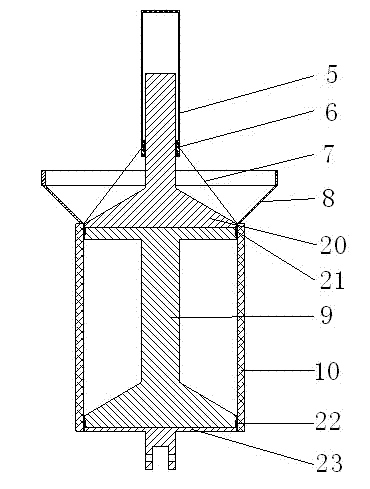

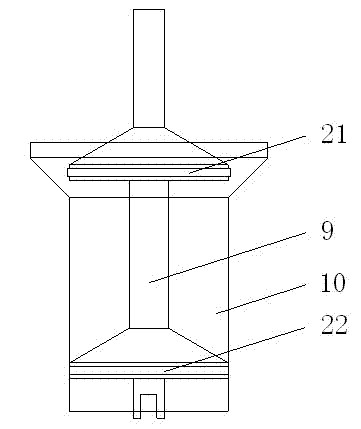

[0035] like Figure 1-4 Shown, the concrete structure of steam explosion machine of the present invention is as follows:

[0036] It includes feed hopper 4, receiving hopper 8, discharge hopper 18, burst chamber 10, sliding sealing disc 9, upper limit shaft 20, lower sealing disc 23, upper sealing ring 21, lower sealing ring 22, cylinder A15, cylinder B17 and Frame 19, described feeding hopper 4 is the conical shape of up big and down small, and its below connects conical receiving hopper 8, and the below of receiving hopper 8 connects blasting bin 10, and discharging hopper 18 is located at the below of blasting bin 10, The discharge hopper is connected with the frame, and the frame 19 supports the discharge hopper 18, and the discharge hopper will collect all the materials that burst into bags.

[0037] Among them: the upper limit shaft is set on the top of the sliding sealing plate and is located in the receiving hopper, which is used to limit the upward movement of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com