Movable intelligent shot blasting machine for plane

A technology of planar movement and shot blasting machine, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, buildings, etc., to achieve the effect of facilitating maintenance and replacement, simple structure, and avoiding dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific embodiments.

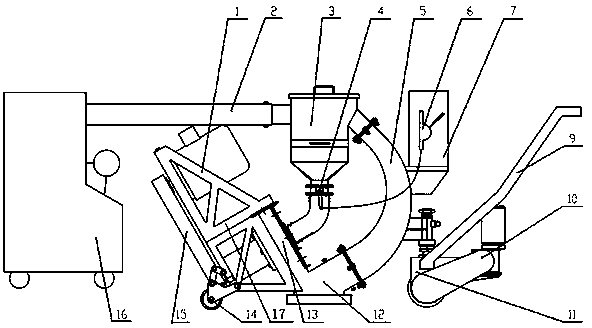

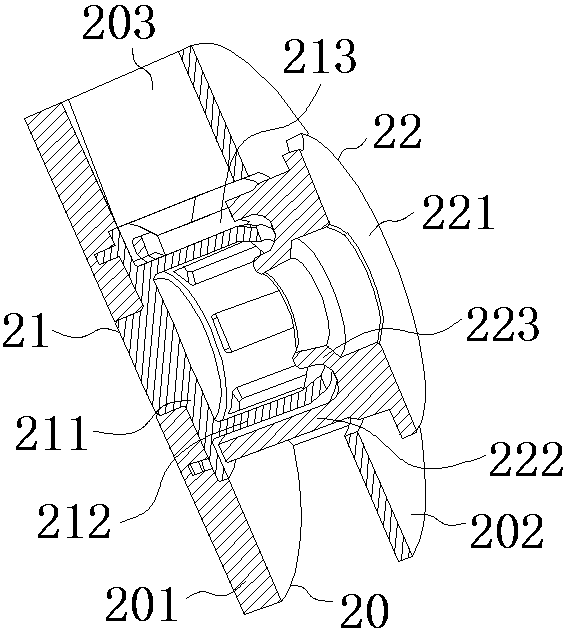

[0023] Such as figure 1 and figure 2 Shown: a plane mobile intelligent shot blasting machine, including a frame 17 and a shot blasting device arranged on the frame 17, a circulation system and a walking system, the shot blasting device includes a shot blasting motor 1, which is sequentially connected by transmission, Transmission device 15 and shot blasting device 13; Described circulatory system comprises the high-pressure rebound chamber 12 that is connected with each other and forms circulation path, recovery pipeline 5, separation bin 3 and described blast device 13; Described high-pressure rebound chamber 12 is positioned at The shot blaster 13 is obliquely below and has an inlet connected to the shot blasting port of the shot blaster 13 in a straight line, and an outlet connected to the lower end of the recovery pipe 5. The high-pressure rebound chamber al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com