Full-automatic angle steel processing device and method

A processing device and fully automatic technology, applied in the field of angle steel processing, can solve the problems of poor factory efficiency and low angle steel production and processing efficiency, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

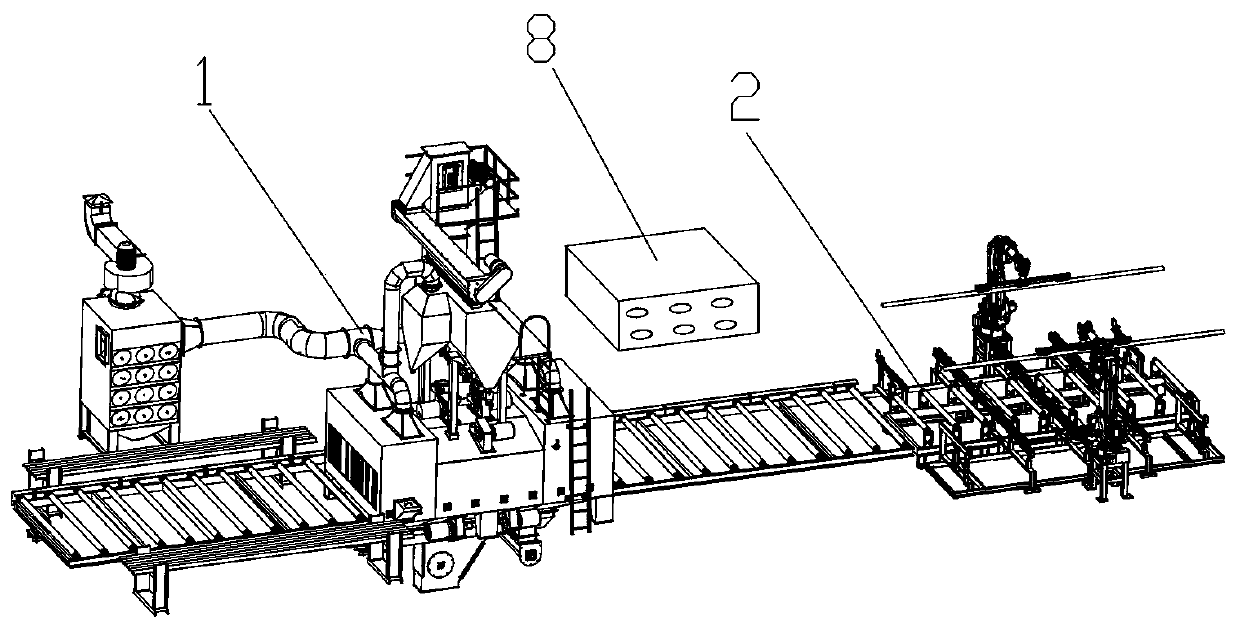

[0063] Such as Figure 1-22 As shown, a kind of automatic angle steel processing device provided in this embodiment includes:

[0064] A shot blasting machine 1 is used to process the oxide layer on the surface of the angle steel;

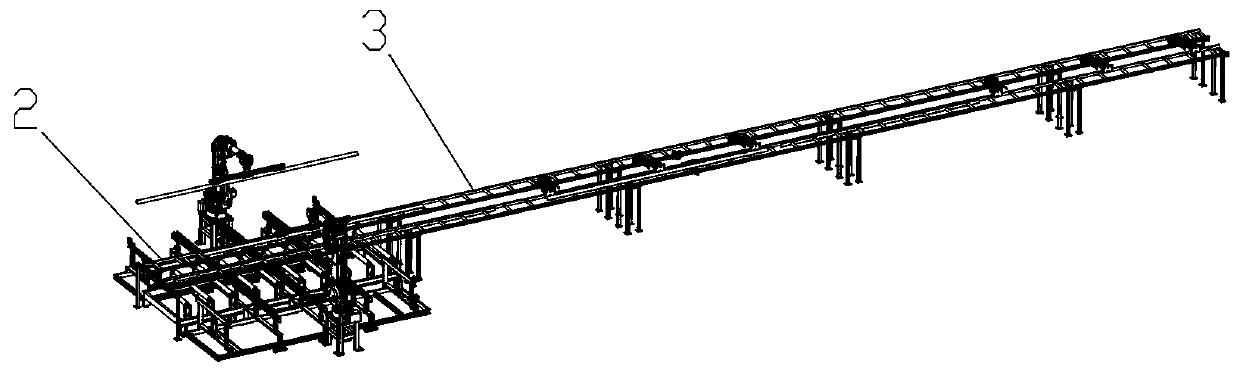

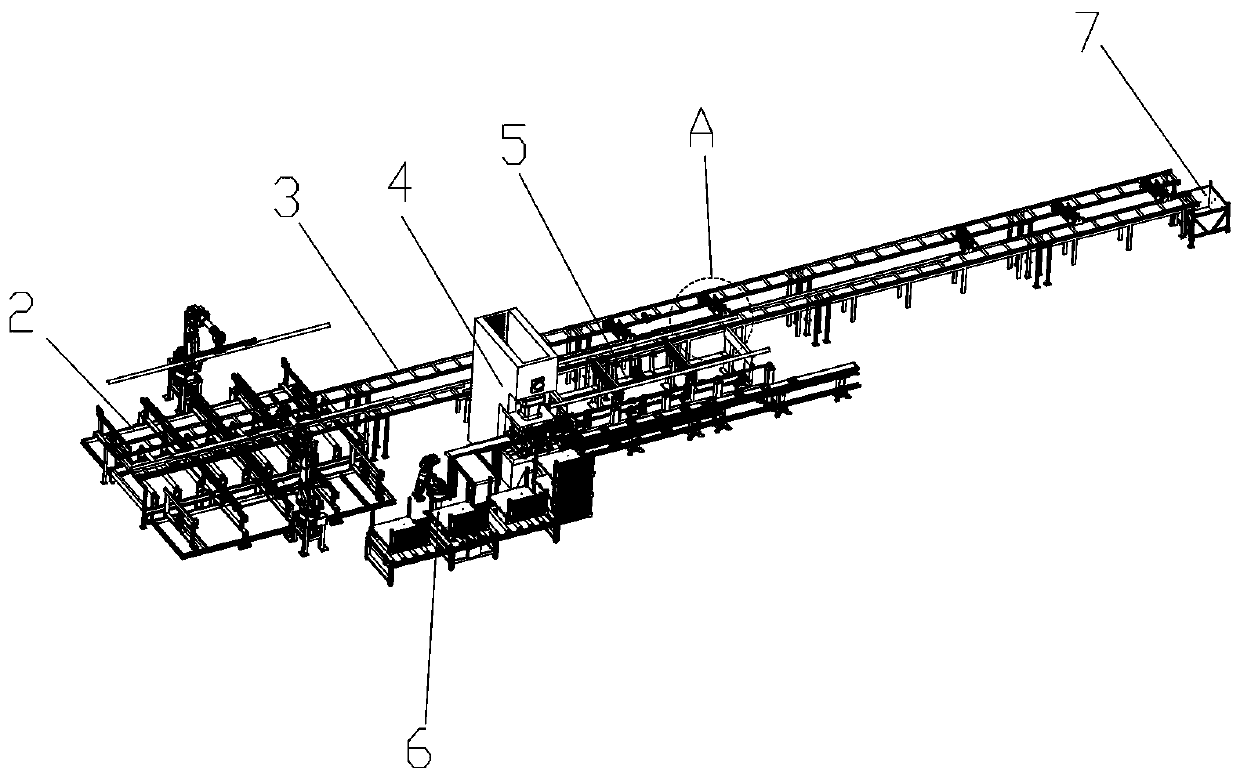

[0065] A diversion platform 2 connected with the shot blasting machine 1, used to divert different types of angle steel;

[0066] Two processing conveyor belts 3 are used to transport the angle steel of the distribution platform 2;

[0067] There are two punching and cutting integrated molds 4 on the side of each processing conveyor belt 3, which are used for angle steel cutting to length and side punching;

[0068] Four stamping conveying mechanisms 5 are used to convey the angle steel on the processing conveyor belt 3 to the corresponding punching integrated mold 4;

[0069] Four stacking mechanisms 6 are used for sorting and stacking the angle steel processed by the corresponding punching integrated mold 4;

[0070] A waste material collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com