Low-temperature micro-abrasive-material air jet flow processing machine tool

A technology for processing machine tools and material gas, which is applied in the direction of abrasive jetting machine tools, abrasive materials, metal processing equipment, etc. It can solve the problems of difficult recovery of abrasive materials and blockage of jet nozzles, etc., and achieves simple structure, continuous adjustment of jet pressure, and operation to prevent liquid nitrogen frostbite personnel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

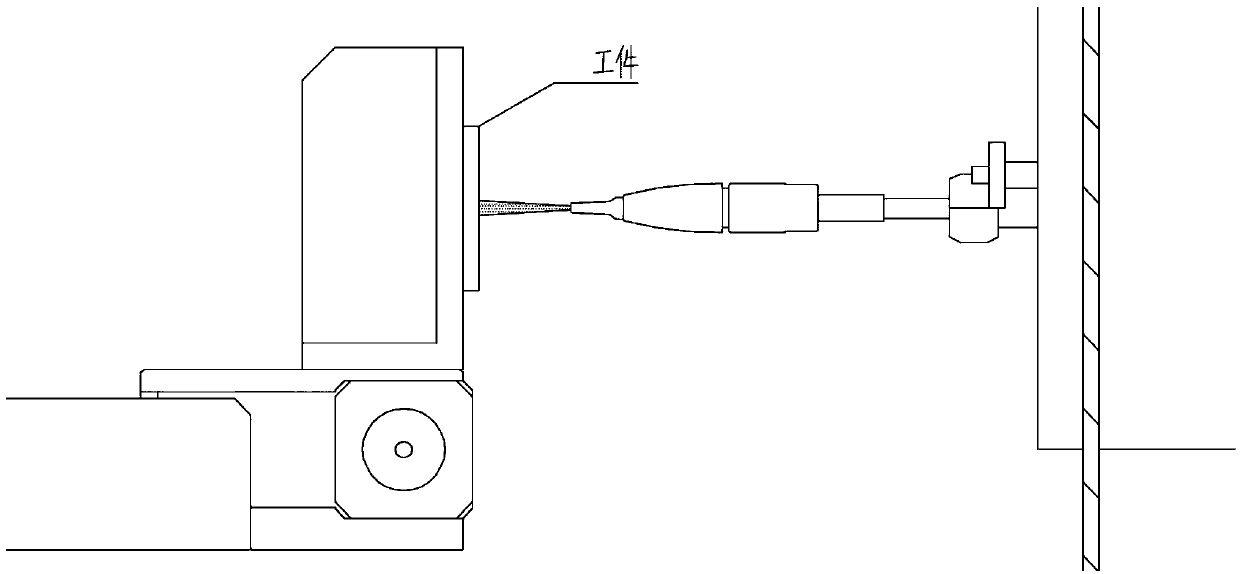

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as Figure 1-2 shown.

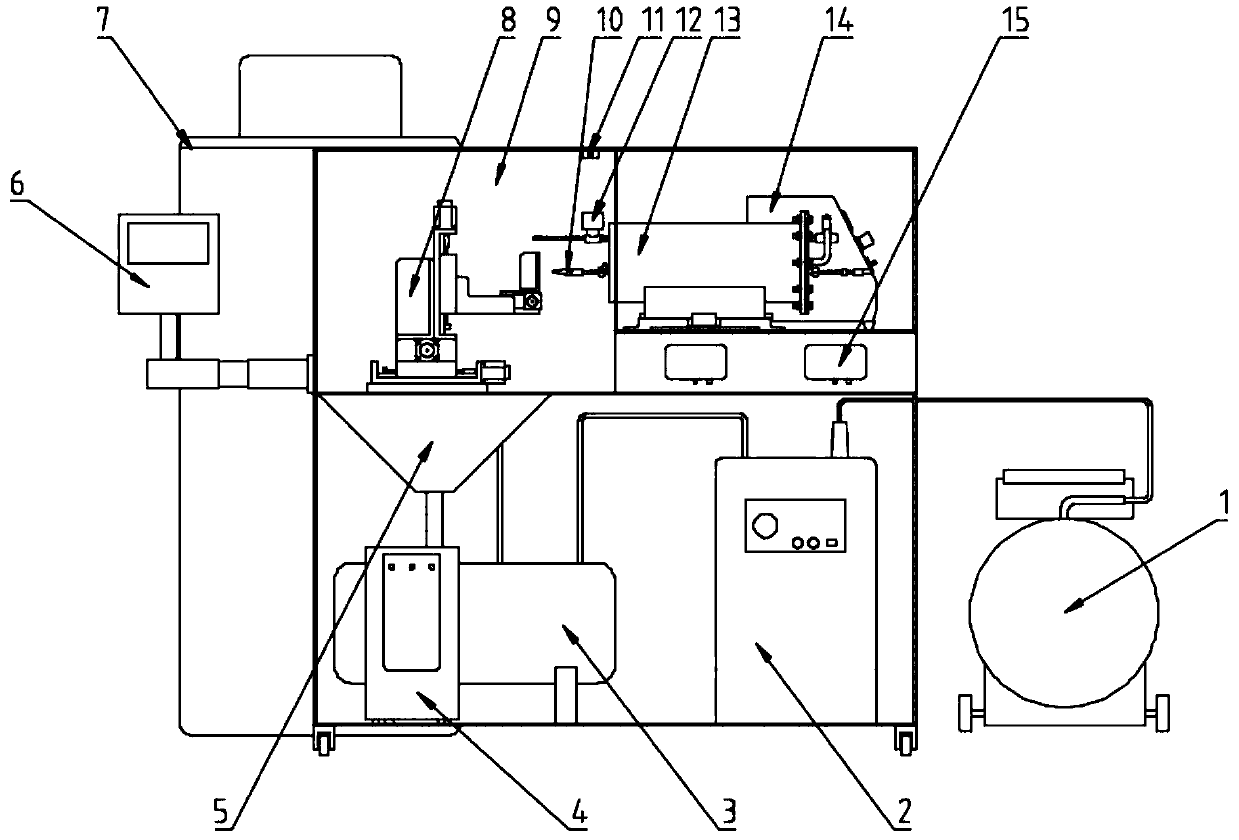

[0030] A low-temperature micro-abrasive air-jet processing machine tool, including a micro-abrasive air-jet generation part, a cooling part, a processing part, an abrasive recovery part, and a controller part, such as figure 1 As shown; the micro-abrasive air jet generation part mainly includes an air compressor 1, an air dryer 2, an air storage tank 3 and a sandblasting machine 14, and the air storage tank 3 is used to keep the injected low-temperature micro-abrasive air jet at one Stable pressure, the sand blasting machine 14 can realize the pressure and flow adjustment of the jet, the air outlet of the air compressor 1 is connected with the air inlet of the air dryer 2, the air outlet of the air dryer 2 is connected with the air inlet of the air storage tank 3 While being connected, it is connected with the processing chamber 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com