Cookware with high wear resistance and manufacturing method of cookware

A technology of high wear resistance and pots and pans, applied in special materials for cooking utensils, kitchen utensils, cooking utensils, etc., can solve the problems of high production cost, increased non-stick protective layer covering ability, poor wear resistance, etc. Enhance the effect of anti-shovel and anti-scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

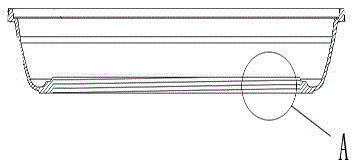

[0030] Embodiment 1 A method for preparing a cooking pot with high wear resistance comprises the following steps:

[0031] 1) The pot body is die-cast;

[0032] 2) Metalworking; CNC lathes;

[0033] 3) Refining; polishing;

[0034] 4) Degreasing the pot surface, degreasing machine after treatment, and high temperature sintering to remove oxides;

[0035] 5) Clean the pot body, clean the pot body with pure water, 3% alcohol solution, and oil-dissolving agent, and dry it;

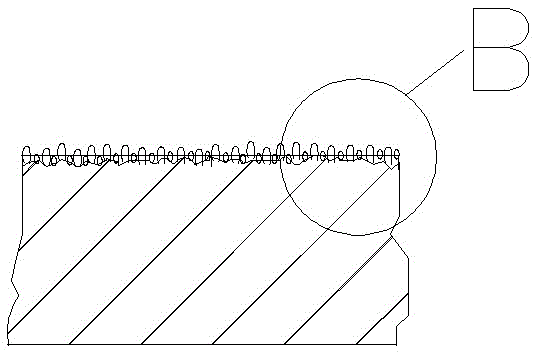

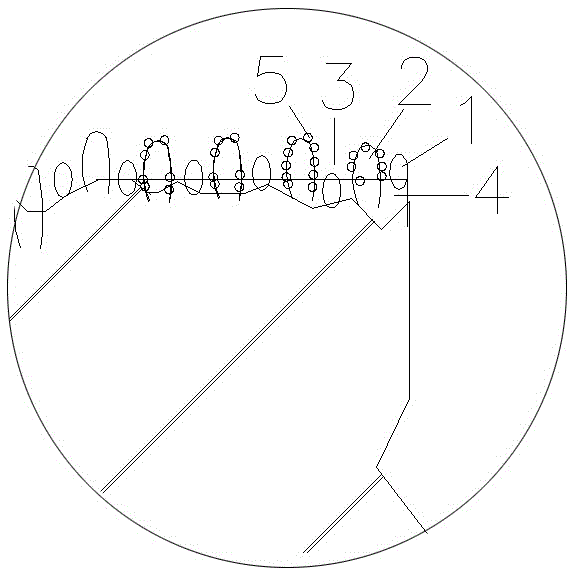

[0036]6) Ensure that the base material of the pot body is clean, dust-free and oil-free before spraying; preheat and sinter, and heat the base material of the pot body to 310-430 degrees. (about 6 catties), 45-60 corundum is sandblasted on the surface of the pot to further roughen the surface of the pot body, and the roughness reaches Ra (2-6) microns;

[0037] 7) Secondary spraying: The pot body after cleaning again is uploaded to the spraying machine, and the ingredients are sprayed material; the sprayed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com