Machining method of three-layer clad steel plate

A processing method and layer compounding technology, which is applied in the processing field of three-layer composite steel plate, can solve the problems of affecting the airtightness of the seal, difficult connection, inability to adapt to the high temperature environment of the heating furnace, etc., and achieve the effect of eliminating waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

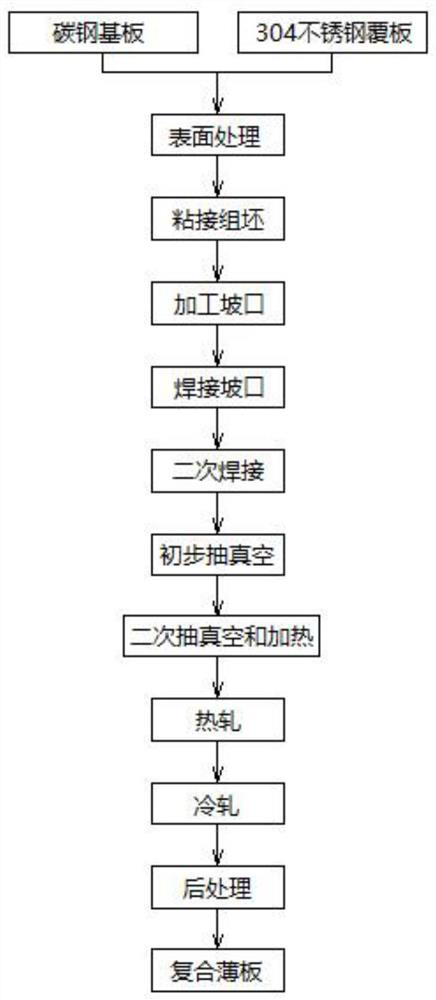

[0039] see figure 1 , one substrate is made of carbon steel plate, and the two cladding plates are made of stainless steel plate. The specific processing steps are as follows:

[0040] S1. Surface treatment: Surface treatment is carried out on the surface to be bonded of the substrate and the surface to be bonded of the cover plate, that is, the two sides of the substrate and one side of the cover plate respectively, and the surface to be bonded of the substrate and the surface to be bonded of the cover plate are removed. Sticky sand and scale.

[0041] Specifically, the substrate is sent into the shot blasting machine, and the shot blasting device of the shot blasting machine throws projectiles (steel balls) at high speed, impacts the two sides of the substrate respectively, and removes the sticky sand and scale on both sides until the surface is clean and free of rust. ; Send the cladding plate into the shot blasting machine, and the shot blaster of the shot blasting machin...

Embodiment 2

[0056] see figure 1 , one substrate is made of carbon steel plate, and the two cladding plates are made of stainless steel plate. The specific processing steps are as follows:

[0057] S1. Surface treatment: Surface treatment is carried out on the surface to be bonded of the substrate and the surface to be bonded of the cover plate, that is, the two sides of the substrate and one side of the cover plate respectively, and the surface to be bonded of the substrate and the surface to be bonded of the cover plate are removed. Sticky sand and scale.

[0058] Specifically, the substrate is sent into the shot blasting machine, and the shot blasting device of the shot blasting machine throws projectiles (steel balls) at high speed, impacts the two sides of the substrate respectively, and removes the sticky sand and scale on both sides until the surface is clean and free of rust. ; Send the cladding plate into the shot blasting machine, and the shot blaster of the shot blasting machin...

Embodiment 3

[0073] see figure 1 , one substrate is made of carbon steel plate, and the two cladding plates are made of stainless steel plate. The specific processing steps are as follows:

[0074] S1. Surface treatment: Surface treatment is carried out on the surface to be bonded of the substrate and the surface to be bonded of the cover plate, that is, the two sides of the substrate and one side of the cover plate respectively, and the surface to be bonded of the substrate and the surface to be bonded of the cover plate are removed. Sticky sand and scale.

[0075] Specifically, the substrate is sent into the shot blasting machine, and the shot blasting device of the shot blasting machine throws projectiles (steel balls) at high speed, impacts the two sides of the substrate respectively, and removes the sticky sand and scale on both sides until the surface is clean and free of rust. ; Send the cladding plate into the shot blasting machine, and the shot blaster of the shot blasting machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com