Method for preparing silver nanowire array by using capillary wetting effect

A technology of silver nanowires and wetting effect is applied in the field of preparing silver nanowire arrays, which can solve the problems of poor adhesion of target substrates, complicated preparation process of silver nanowire arrays, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

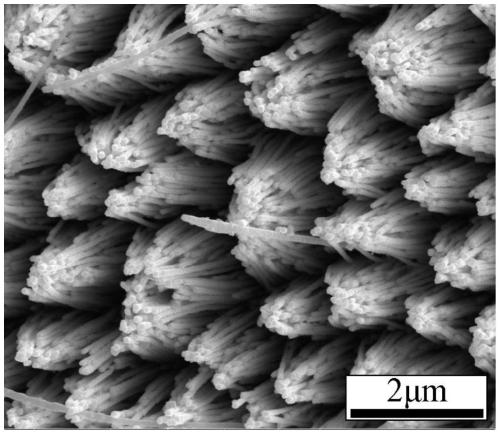

[0024] Specific embodiment 1: This embodiment is a method for preparing silver nanowire arrays by using capillary wetting, specifically according to the following steps:

[0025] 1. Mixed powder: Put Ag powder and CuO powder together into a ball mill jar, add absolute ethanol to completely submerge Ag powder and CuO powder, wet mix ball mill in planetary ball mill for 6h~12h, then take it out, and put it at 90℃~95 Dry in a water bath at ℃ to obtain Ag-CuO mixed powder, and then use a tablet mold to make Ag-CuO mixed powder into Ag-CuO sheets under the pressure of a hydraulic press; the mole of CuO in the Ag-CuO mixed powder The score is 1% to 8%;

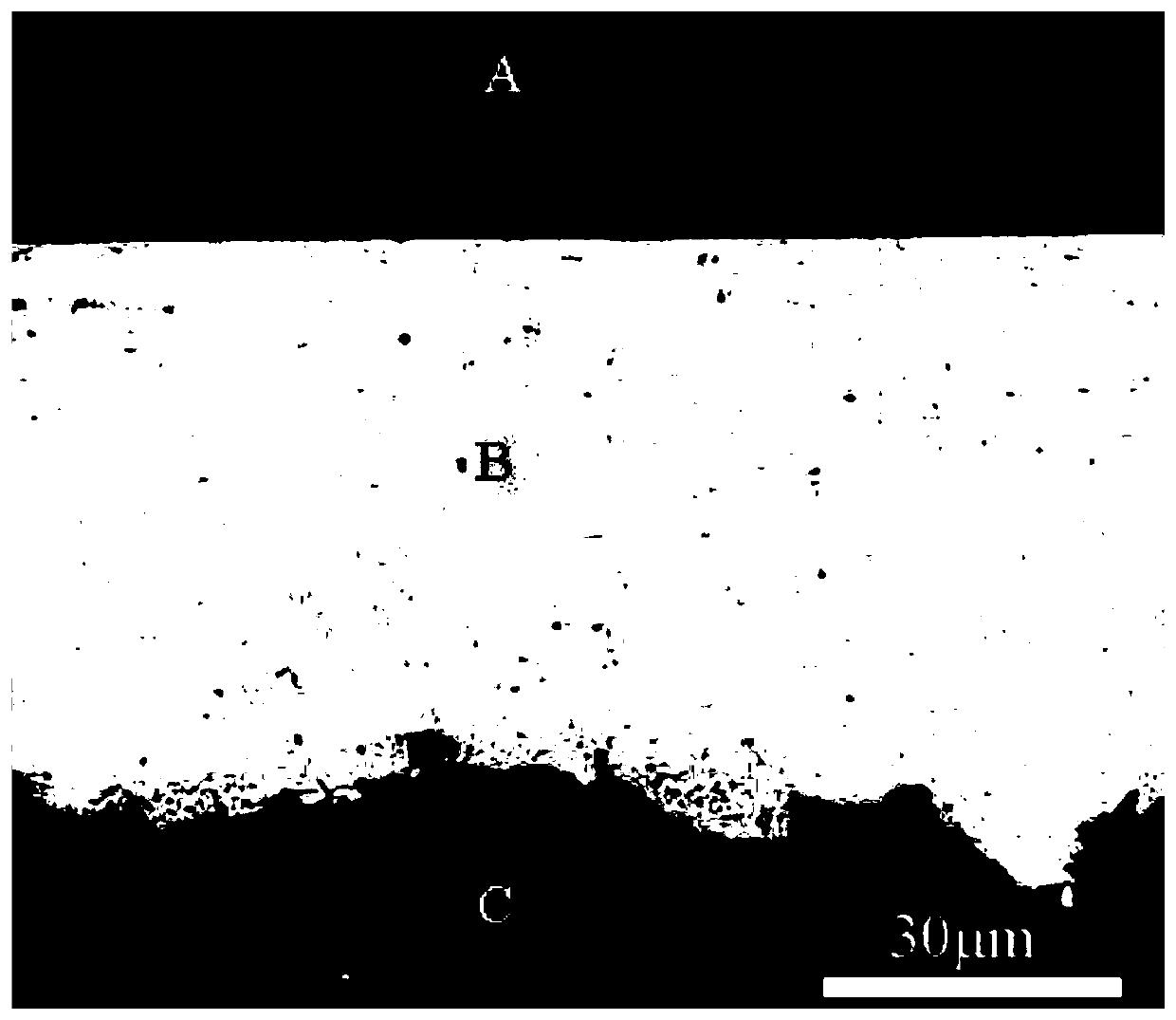

[0026] 2. Heating: polish the base material, and then ultrasonically clean it with absolute ethanol for 5-10 min; rinse the anodized aluminum template in absolute ethanol, and dry it naturally; wash the base material and the Ag- The CuO sheet and the dried anodized aluminum template were stacked together from bottom to top, placed ...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment is different from Embodiment 1 in that the mole fraction of CuO in the Ag-CuO mixed powder described in step 1 is 1%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the base material described in step two is a high-temperature stable ceramic material, specifically Al 2 o 3 or BSCF, BCFN or BCFZ. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com