Manufacturing and processing method of rectangular section dissimilar metals composite wires

A dissimilar metal, rectangular cross-section technology, used in metal processing equipment, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of difficulty in control, low bonding strength between two metals, uneven thickness of the cladding layer, etc., to achieve the production of finished products. High rate and productivity, strong metallurgical bond, dense coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

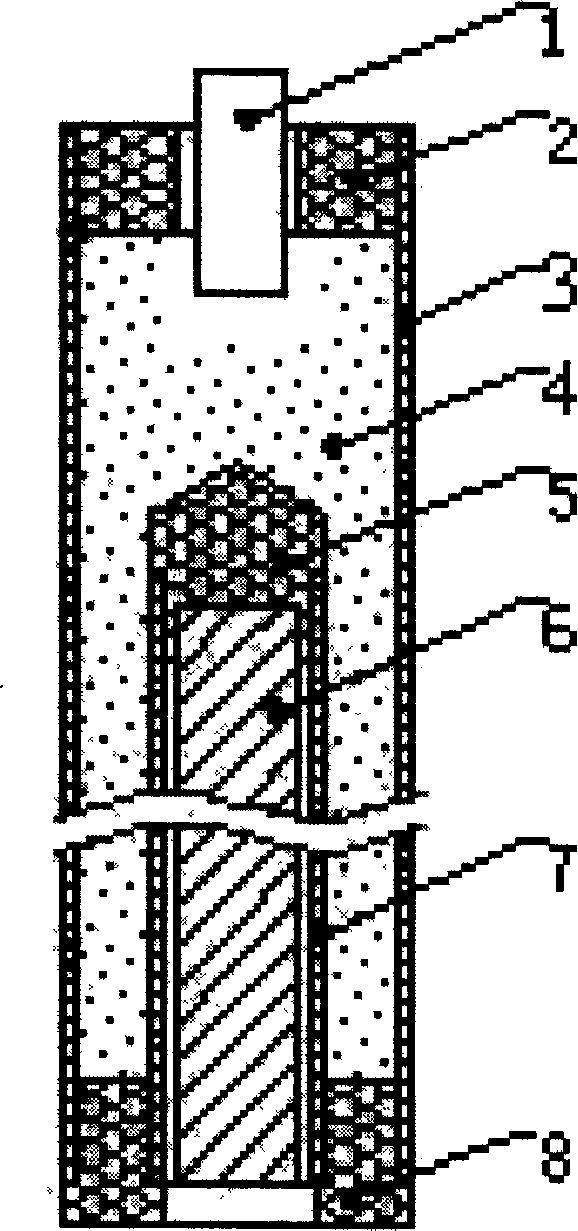

[0021] Referring to the accompanying drawings, this method includes:

[0022] (1), choose the oxygen-free copper tube of wall thickness 1mm as cladding metal tube 7, and carry out degreasing and cleaning to its inner surface, clean and refresh; choose the molybdenum rod that diameter is 5mm to be metal mandrel 6, to its straightening and surface refresh treatments;

[0023] (2), according to the following steps for assembly and positioning:

[0024] a. Assemble the treated molybdenum rod into the oxygen-free copper tube and install it on the bottom positioning device 8, plug the top positioning device 5 on the top of the oxygen-free copper tube and the molybdenum rod, and place the gap between the inner wall of the oxygen-free copper tube and the molybdenum rod There is a gap of 0.5mm between them;

[0025] b. Place the assembled oxygen-free copper tube and molybdenum rod in the cylindrical casing 3, and place the bottom positioning device 8 at the bottom of the cylindrical ...

Embodiment 2

[0031] Referring to accompanying drawing, its preparation method sees embodiment 1, selects the 30CrMnSi steel pipe of wall thickness 1.5mm to be cladding metal pipe, and its inner surface is degreased and cleaned, cleans and refreshes; Choose the T2 copper rod that diameter is 8mm, its Alignment and surface refresh treatment; then install and assemble according to the attached drawings, requiring a 2.5mm explosion gap between the inner wall of the 30CrMnSi steel pipe and the T2 copper rod; use No. 2 rock explosives, the radial explosive thickness is 50mm, and detonate the electric detonator; obtain 30CrMnSi Steel pipe / T2 copper core bimetallic composite billet, the interface shear bonding strength is greater than the T2 copper matrix strength (shear fracture occurs in the copper matrix); annealing at a temperature of 800 ° C - drawing multiple cycles to process to the required diameter Circular composite wire; annealed and cold-rolled to obtain a finished product of rectangula...

Embodiment 3

[0033] Referring to accompanying drawing, its preparation method sees embodiment 1, chooses the pure silver tube of wall thickness 1mm to be coating metal tube 7, and its inner surface is carried out degreasing cleaning; and surface refresh treatment; then install and assemble according to the attached drawings, requiring a 1.5mm explosion gap between the inner wall of the pure silver tube and the pure aluminum rod; use No. 2 rock ammonium antimony / wood powder / NaCl mixed explosive, and the radial explosive thickness is 25mm , detonate the electric detonator; obtain pure silver tube / aluminum core bimetal composite billet; anneal at a temperature of 350°C and draw for multiple cycles to process a circular composite wire with a diameter of Φ0.03mm±0.002mm; anneal, cold-roll A finished product of a rectangular cross-section dissimilar metal composite wire is obtained. Its elongation ≥ 7%; strength σb ≥ 200Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com