Self-temperature limiting heat tracing belt with dual-layer resin conductor and manufacturing method thereof

A self-limiting temperature heating cable and heating cable technology, applied in the direction of coating, heating element material, heating element shape, etc. Improve the effect of driving productivity and product quality, performance innovation, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

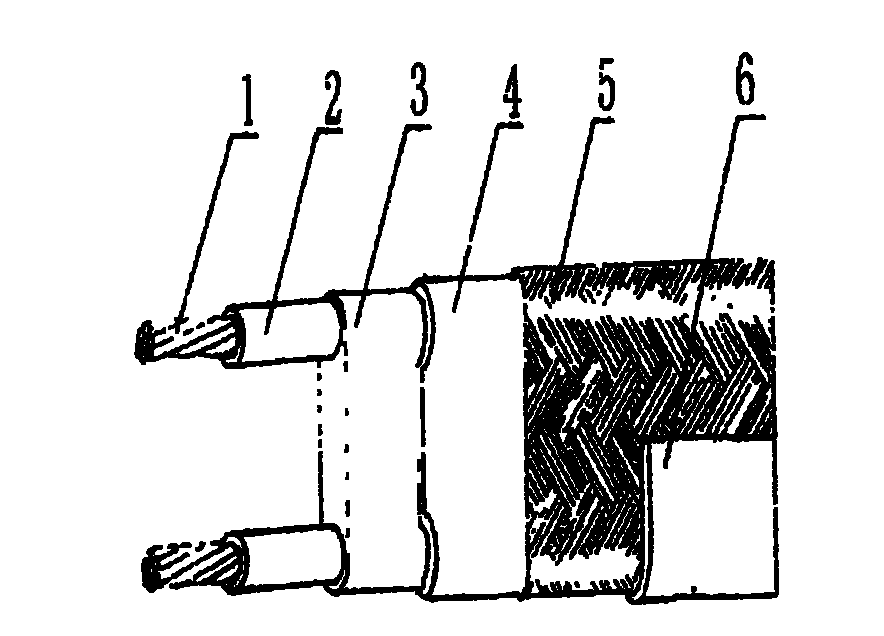

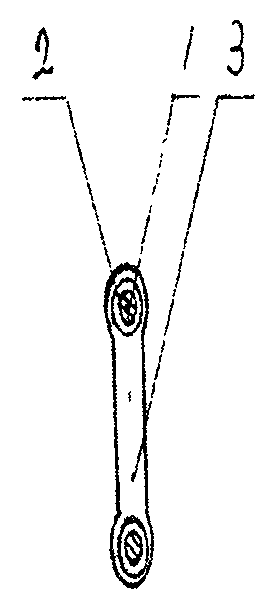

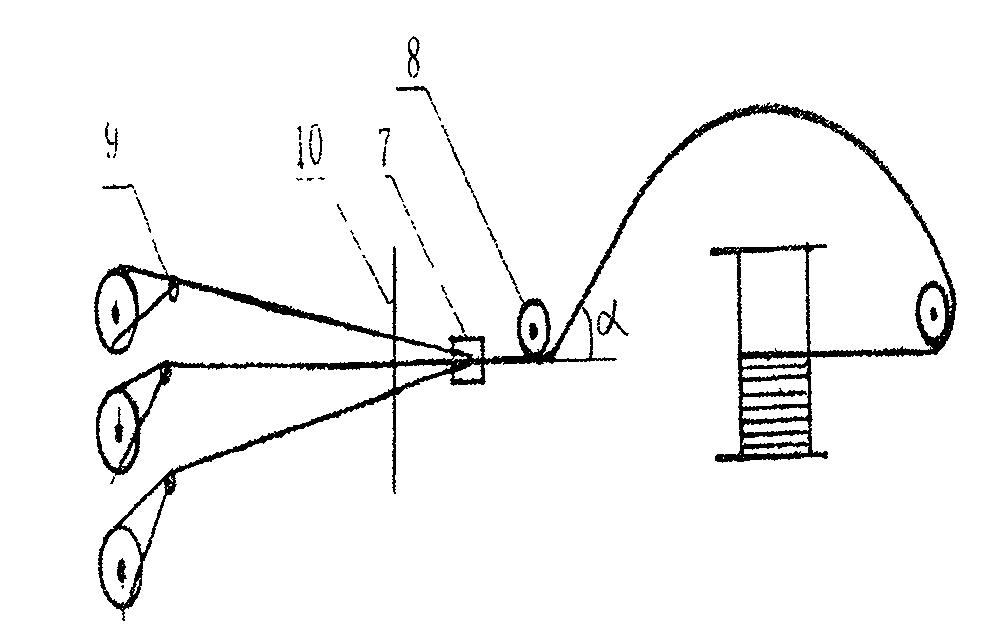

[0063] A self-limiting temperature heating cable with a double-layer resin conductor, the heating cable includes two parallel conductive metal electrodes 1, each metal conductive electrode 1 is coated with a layer of resin conductor layer 2, and the two metal conductive electrodes 1 are coated with a resin conductor layer 2. The conductive electrode 1 is in close contact with the heating body 3 through the resin conductor layer 2 to form a parallel circuit. The heating body 3 is covered with an insulating layer 4, and there is a layer of sheath 6 outside the insulating layer 4. The thickness of the insulating layer 4 is 0.5mm, a shielding layer 5 is provided between the insulating layer 4 and the sheath 6, and the shielding layer 5 is made of tinned copper wire or aluminum-magnesium alloy wire. The resin conductor layer 2 is made of a high Made of molecular resin conductive material, the formula of resin conductor layer 2 is as follows by weight: 100 parts of high-density polye...

Embodiment 2

[0077] A self-limiting temperature heating cable with a double-layer resin conductor, the heating cable includes two parallel conductive metal electrodes 1, each metal conductive electrode 1 is coated with a layer of resin conductor layer 2, and the two metal conductive electrodes 1 are coated with a resin conductor layer 2. The conductive electrode 1 is in close contact with the heating body 3 through the resin conductor layer 2 to form a parallel circuit. The heating body 3 is covered with an insulating layer 4, and there is a layer of sheath 6 outside the insulating layer 4. The thickness of the insulating layer 4 is 0.7mm, a shielding layer 5 is provided between the insulating layer 4 and the sheath 6, the shielding layer 5 is made of tinned copper wire or aluminum-magnesium alloy wire, and the resin conductor layer 2 is made of a 0.2mm thick Made of molecular resin conductive material, the formula of resin conductor layer 2 is as follows by weight: 100 parts of low-density...

Embodiment 3

[0089] A self-limiting temperature heating cable with a double-layer resin conductor, the heating cable includes two parallel conductive metal electrodes 1, each metal conductive electrode 1 is coated with a layer of resin conductor layer 2, and the two metal conductive electrodes 1 are coated with a resin conductor layer 2. The conductive electrode 1 is in close contact with the heating body 3 through the resin conductor layer 2 to form a parallel circuit. The heating body 3 is covered with an insulating layer 4, and there is a layer of sheath 6 outside the insulating layer 4. The thickness of the insulating layer 4 is 0.6mm, a shielding layer 5 is provided between the insulating layer 4 and the sheath 6, the shielding layer 5 is made of tinned copper wire or aluminum-magnesium alloy wire, and the resin conductor layer 2 is made of a 0.2mm thick Made of molecular resin conductive material, the formula of resin conductor layer 2 is as follows by weight: 100 parts of high-densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com