Self-temperature limiting heat tracing belt and manufacturing method thereof

A self-limiting temperature heating cable, heating cable technology, applied in the direction of heating element material, heating element shape, ohmic resistance heating parts, etc., can solve the problem of self-limiting temperature heating cable starting current, unstable performance, heating cable burning problems, to achieve the effect of improving productivity and product quality, performance innovation, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

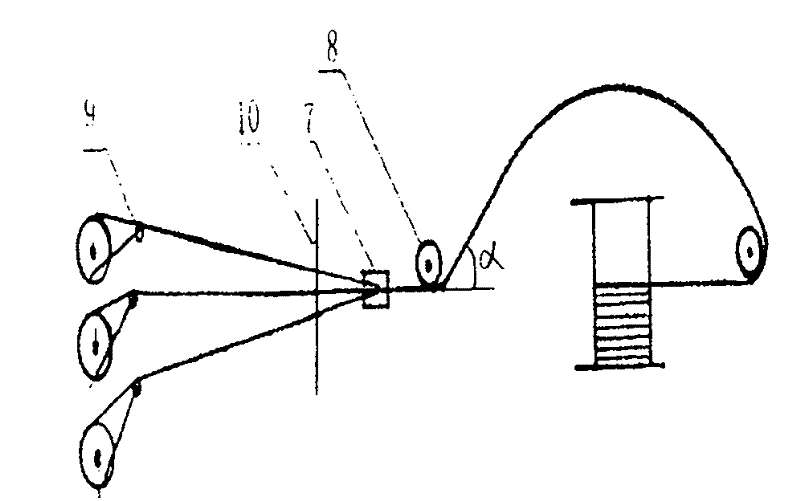

[0049] A kind of preparation method of self-limiting temperature tracing tape is characterized in that: the method is carried out according to the following steps:

[0050] A. Preparation of metal conductive electrodes: using a wire harness machine to twist equal tension stranded wires as metal conductive electrodes 1;

[0051] B. Material selection and preparation of the resin conductor layer: take each raw material for use in the following proportions: 100 parts of low-density polyethylene or high-density polyethylene, 5-12 parts of PE-EVA three-layer anti-aging composite shed film, 40 parts of acetylene carbon black ~45 parts, 0.6~0.8 parts of triallyl isocyanurate, 0.3~0.5 parts of octadecyl (3.5-di-tert-butyl-4-hydroxyphenyl) propionate, bis-thiodipropionate 0.2-0.5 part of dodecyl ester, 0.2-0.3 part of zinc stearate.

[0052] After drying low-density polyethylene or high-density polyethylene at 60-80 ℃ for 2-6 hours, it can effectively prevent the problem of rough surf...

Embodiment 1

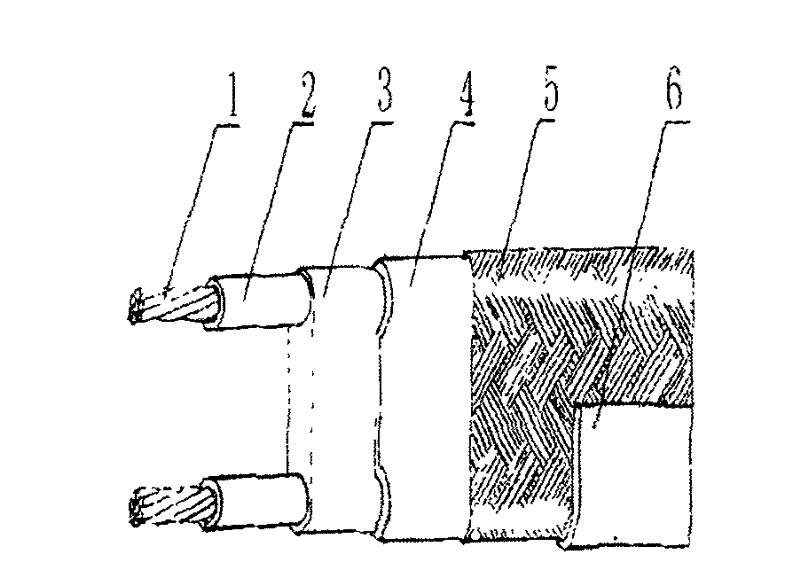

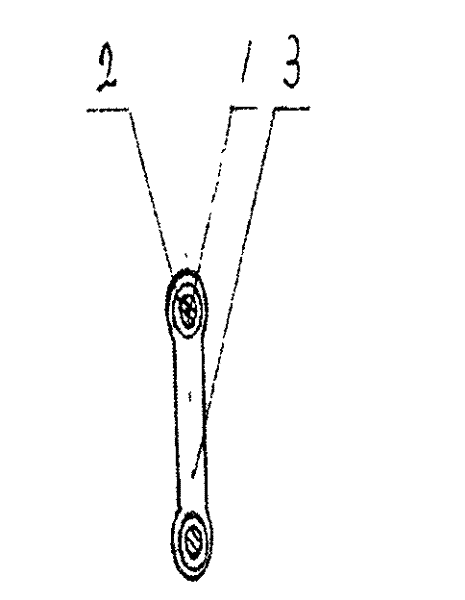

[0063]A self-limiting temperature heating cable, the heating cable includes two power transmission metal conductive electrodes 1 arranged in parallel, each metal conductive electrode 1 is covered with a resin conductor layer 2, and the two metal conductive electrodes 1 pass through the resin conductor. The layer 2 is in close contact with the heating body 3 to form a parallel circuit. The heating body 3 is covered with an insulating layer 4, and there is a layer of sheath 6 on the outside of the insulating layer 4. The thickness of the insulating layer 4 is 0.5mm. A shielding layer 5 is arranged between the layer 4 and the sheath 6. The shielding layer 5 is made of tinned copper wire or aluminum-magnesium alloy wire. The resin conductor layer 2 is made of a polymer resin conductive material with a thickness of 0.1 mm. , the resin conductor layer 2 formula is as follows by weight: 100 parts of high-density polyethylene (HDPE), 5 parts of PE-EVA three-layer anti-aging composite s...

Embodiment 2

[0077] A self-limiting temperature heating cable, the heating cable includes two power transmission metal conductive electrodes 1 arranged in parallel, each metal conductive electrode 1 is covered with a resin conductor layer 2, and the two metal conductive electrodes 1 pass through the resin conductor. The layer 2 is in close contact with the heating element 3 to form a parallel circuit. The heating element 3 is covered with an insulating layer 4, and there is a layer of sheath 6 on the outside of the insulating layer 4. The thickness of the insulating layer 4 is 0.7mm. A shielding layer 5 is arranged between the layer 4 and the sheath 6. The shielding layer 5 is made of tinned copper wire or aluminum-magnesium alloy wire. The resin conductor layer 2 is made of a polymer resin conductive material with a thickness of 0.2 mm. , the resin conductor layer 2 formula is as follows by weight: 100 parts of low-density polyethylene, 10 parts of PE-EVA three-layer anti-aging composite s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com