A method for preparing perovskite solar cells based on two-dimensional material graphene phase carbon nitride

A technology of olefinic carbon nitride and solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., to achieve the effects of simple and easy to obtain, slow down volatilization, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: use g -C 3 N 4 Preparation of perovskite solar cells by doping perovskite precursor solution:

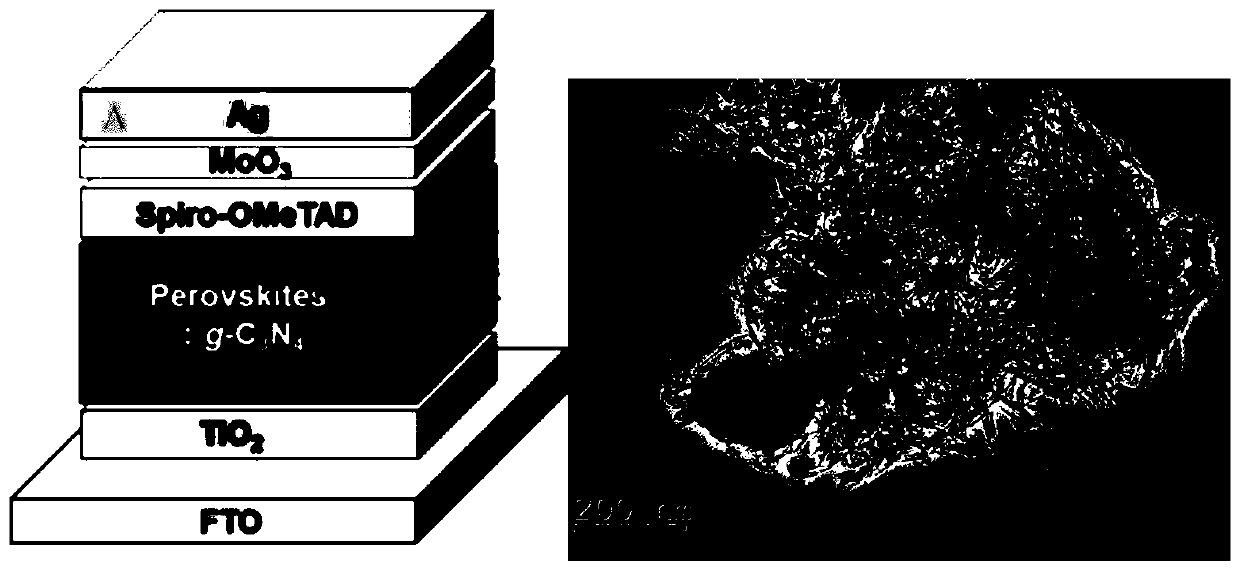

[0033] The device structure of the battery is: FTO / TiO 2 / Perovskite layer (Perovskite) / Spiro-OMeTAD / MoO 3 / Ag

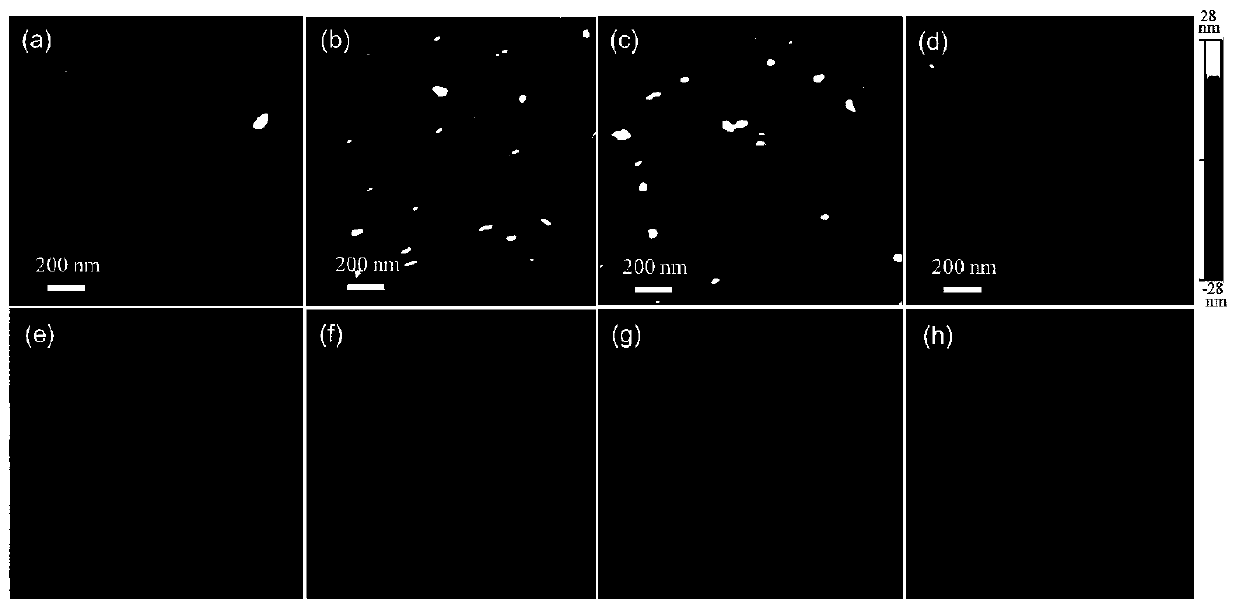

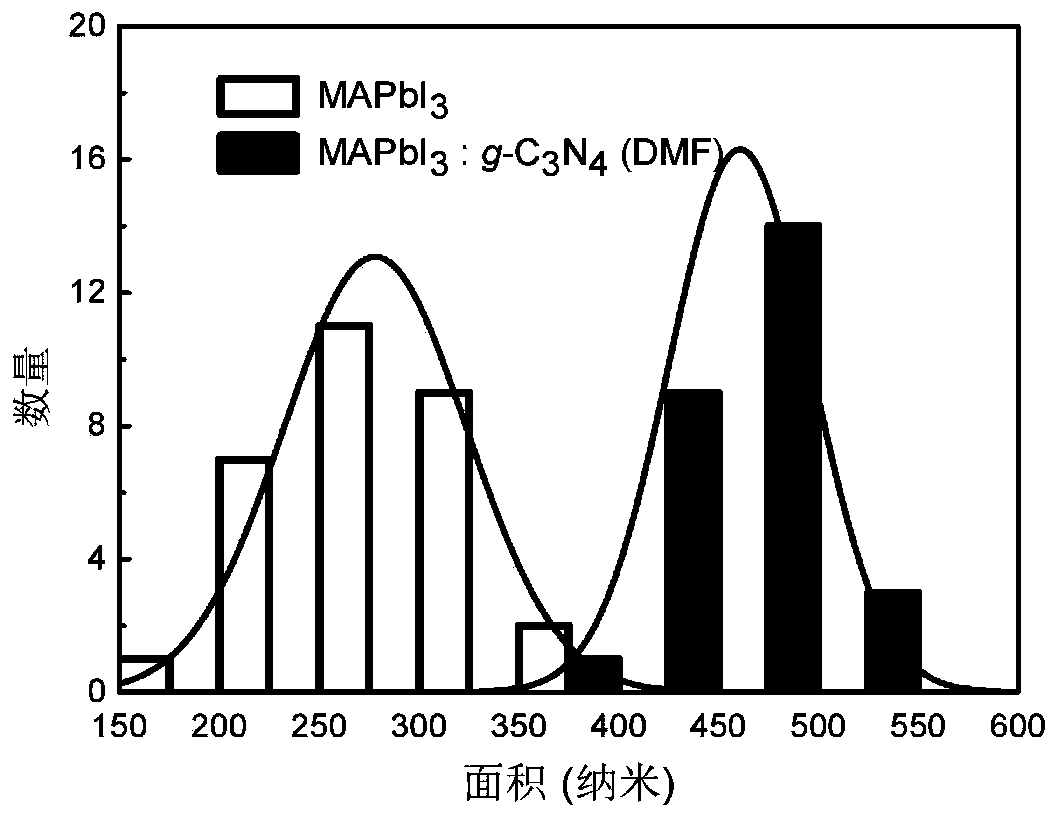

[0034] The preparation method of perovskite precursor solution in this example is as follows: g -C 3 N 4 Different solvents are used to configure the precursor additives. The solvents used are DMF, DMSO, and ethanol respectively. The precursor additives are added to the perovskite precursor solution according to a certain doping ratio. The preparation method of the perovskite precursor is as follows: MAI with PbI 2 The molar ratio is 1:1, that is, 1 mole is weighed and added to 1 ml of mixed solvent DMSO and GBL, and the volume ratio of DMSO and GBL in the mixed solvent is 3:7. The amount of precursor additive added is 30 μL, each solvent configuration g -C 3 N 4 The doping mass fractions were 0.30 wt%, 0.60 wt%, 1.20 wt%, respectively. ...

Embodiment 2

[0040] Embodiment 2: with doping g -C 3 N 4 The perovskite precursor solution of the precursor additive is prepared into a perovskite solar cell:

[0041] The device structure of the battery is: FTO / TiO 2 / Perovskite / Spiro-OMeTAD / MoO 3 / Ag

[0042] The preparation method of the perovskite precursor solution in this example is as follows: the configuration g -C 3 N 4 The solvents DMF, DMSO, and ethanol used in the precursor additives were added to the perovskite precursor solution in the same amount as in Example 1 (the amount of the solvent was 30 μL) to prepare a perovskite solar cell device.

[0043] The preparation process of perovskite solar cells:

[0044] (1) The processing method of the substrate is the same as in Example 1, and the deposited TiO 2 The FTO substrate was placed in an ozone machine for 25 minutes of ozone treatment, and then taken out and transferred to the glove box. The perovskite precursor solutions doped and undoped with DMF, DMSO, and ethano...

Embodiment 3

[0048] Embodiment 3: use g -C 3 N 4 (Under the same doping ratio, different configuration solvent conditions) the preparation process of doping perovskite precursor solution to prepare perovskite solar cells:

[0049] The device structure of the battery is: FTO / TiO 2 / Perovskite / Spiro-OMeTAD / MoO 3 / Ag

[0050] The preparation method of perovskite precursor solution in this example is as follows: g -C 3 N 4 Use different solvents to prepare precursor additives. The solvents used are DMF, DMSO, and ethanol respectively. Add calcium Devices are prepared in the titanium ore precursor solution;

[0051] The formation process of the perovskite layer:

[0052] (1) The processing method of the substrate is the same as in Example 1, and the deposited TiO 2 The FTO substrate was placed in an ozone machine for 25 minutes of ozone treatment, and then it was taken out and transferred to the glove box. The doped and undoped perovskite materials were respectively formed on the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com