Series constant-power heat tracing tape and manufacturing method thereof

A manufacturing method and heating cable technology, applied in the direction of electric heating devices, ohmic resistance heating, heating element shape, etc., can solve the problems of difficult control of the quality of heating cables, rough manufacturing methods, etc., to facilitate automatic management, low production costs, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

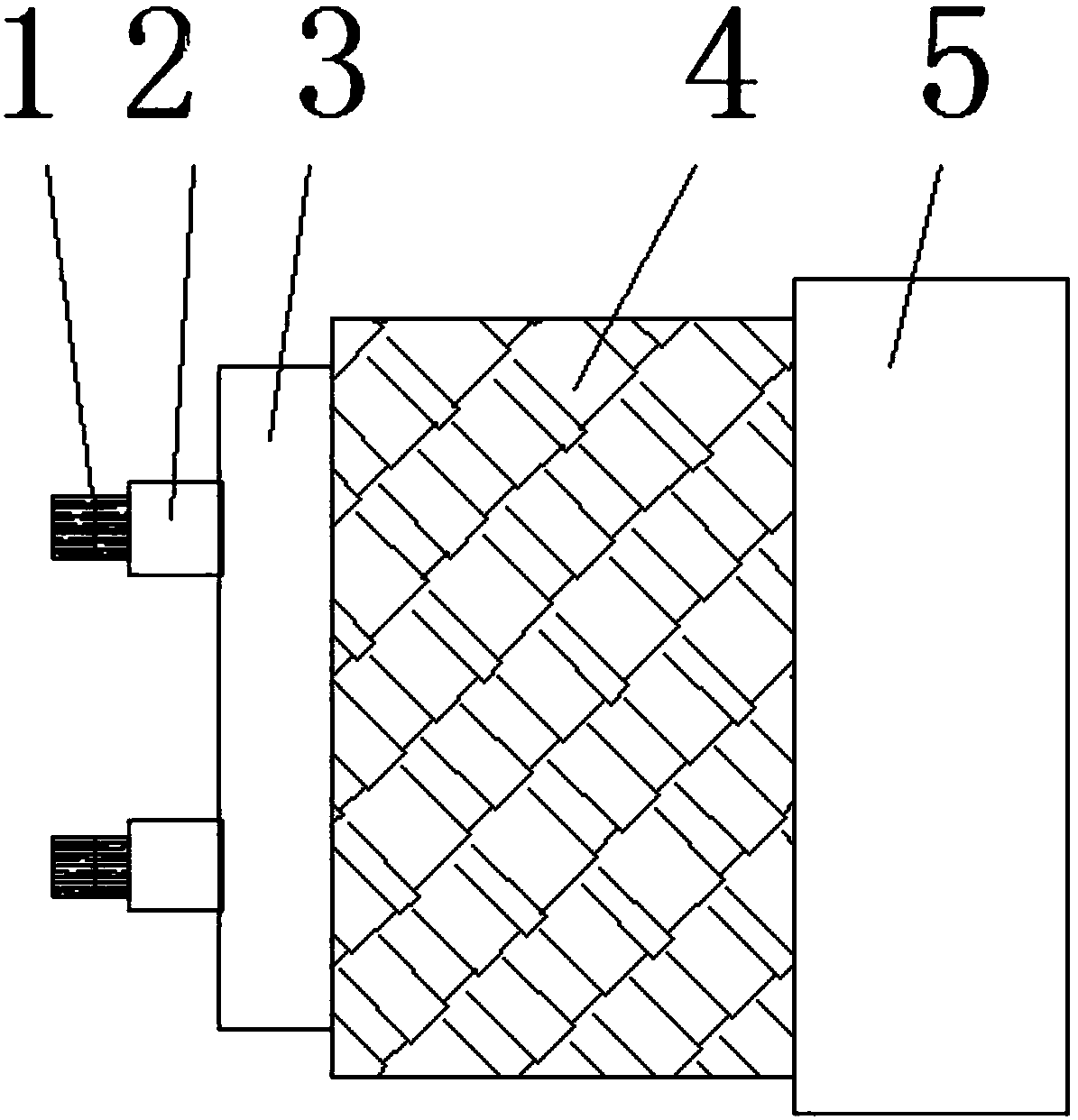

[0032] A series constant power heating cable, including a metal conductive electrode 1, the metal conductive electrode 1 is wrapped with a bus insulating layer 2 and is in close contact with the metal conductive electrode 1 to form a series circuit, and the bus insulating layer 2 is sequentially provided with insulating inner protection Cover 3, metal braided shielding layer 4 and reinforced outer sheath 5.

[0033] In this embodiment, the metal wire electrodes 1 are single-core, double-core or three-core in series.

[0034] A method for manufacturing a series constant power heating cable, comprising the following steps:

[0035] 1) Prepare the metal wire electrode 1: use a beam machine to twist the equal-tension stranded wire as the metal wire e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com