Environmental protecting multifunctional coating and its preparing method

An environmentally friendly and multifunctional technology, applied in conductive coatings, coatings, etc., can solve the problems of poor flame resistance, large expansion coefficient, and low hardness, and achieve the effects of simple preparation process, improved heat resistance, and improved brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

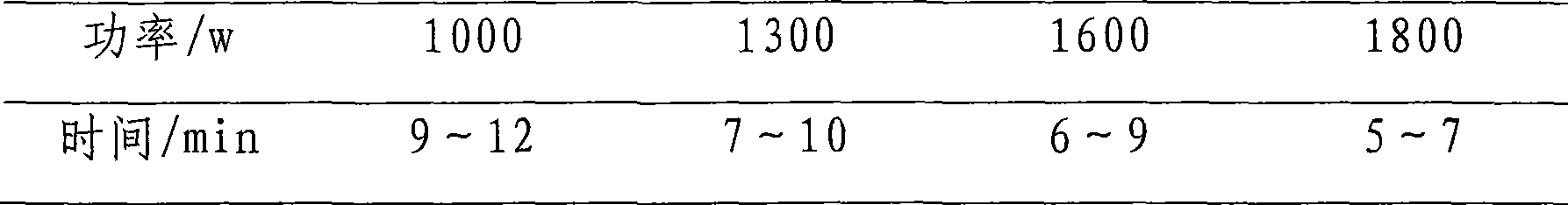

[0016] According to the following table for batching, after batching, mixing, ball milling, stirring, and natural drying to obtain the product.

[0017] Raw materials and process parameters Example 1 Example 2 Example 3 Example 4 Example 5 Silicone resin 10 15 10 11 10 Silica sol 25 20 20 20 20 silver oxide 40 40 45 40 42 Copper oxide 1 1 2.7 1 1 iron oxide 2.7 1 1 5 1 Nickel oxide 1 1 1 2.7 1 spodumene 20 0 0 20 24.6 cordierite 0 21.7 20 0 0 sodium tripolyphosphate 0.1 0.1 0 0.1 0 Hexametaphosphate 0 0 0.1 0 0.1 Polyvinyl alcohol (PVA) 0.05 0.05 0.1 0.1 0.1 SDBS 0.05 0.05 0.05 0.05 0.1 tributyl phosphate 0.1 0.1 0.05 0.05 0.1 Ball milling time (hours) 25 26 24 24 25 Particle size after ball milling 44μm 41μm 43μm 43μm 44μm Spray thickness 200μm 220μm 250μm 270μm 280μm

[0018] According t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com