Method for manufacturing combination of aluminum alloy and thermoplastic resin

A kind of thermoplastic resin, manufacturing method technology, applied in the manufacturing field of aluminum alloy and thermoplastic resin combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited.

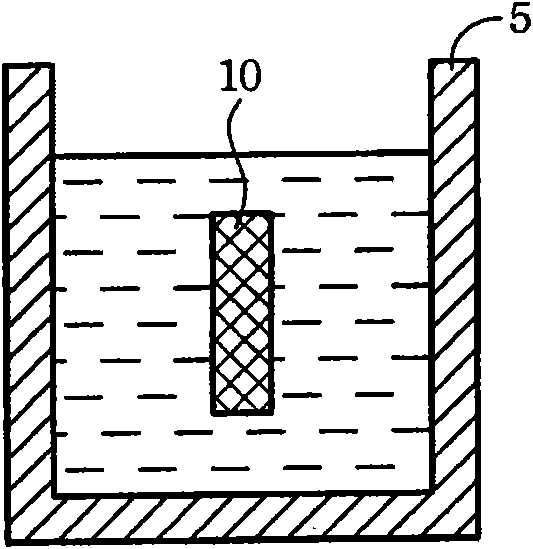

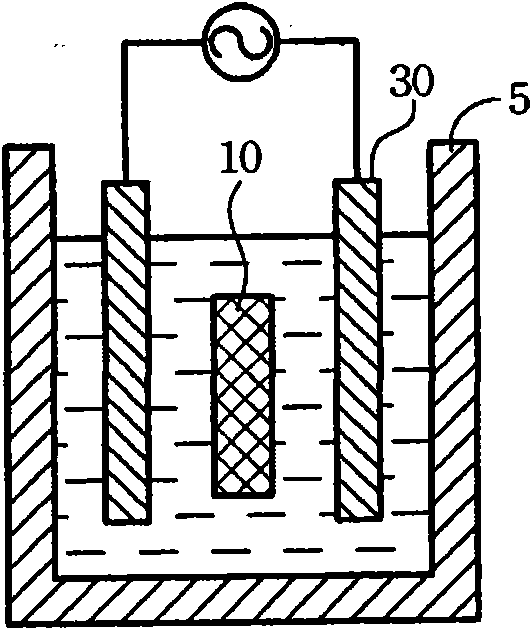

[0037] Please refer to Figure 1a , is a schematic diagram of pretreatment according to a preferred embodiment of the present invention. First of all, 1xxx to 7xxx series aluminum alloys are sliced 10 times before containing NaOH, KOH, NaOH 2 CO 3 The concentration of the solution is about 1-10% molar equivalent, soaking at 20° C. to 60° C. for 10 seconds to 3 minutes to remove grease, dust and dense oxides on the surface of the aluminum alloy.

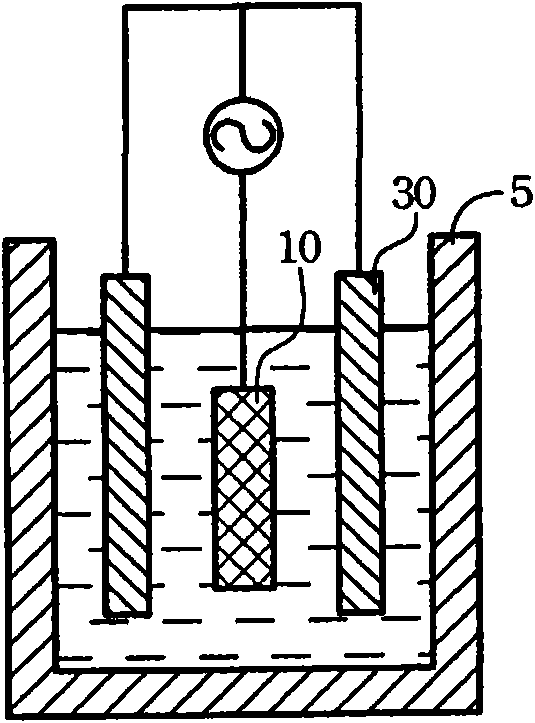

[0038] When the dense oxide on the surface of the aluminum alloy 10 is removed, it is different from soaking in a solution containing amine or amine derivatives in the prior art to form a chemical substance attached to the surface of the aluminum alloy. The method of the present invention is to make the surface of the aluminum alloy 10 larger Staggered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com