Ion implantation of cupper, nickel as pretreatment technique for electroless copper on surface of ceramics

A technology of ion implantation and ceramic surface, which is applied in the field of ion implantation of copper and nickel as a pretreatment process for electroless copper plating on ceramic surfaces. The surface of the copper layer is easy to oxidize and other problems, so as to achieve the effect of good appearance, improved plating efficiency and small porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

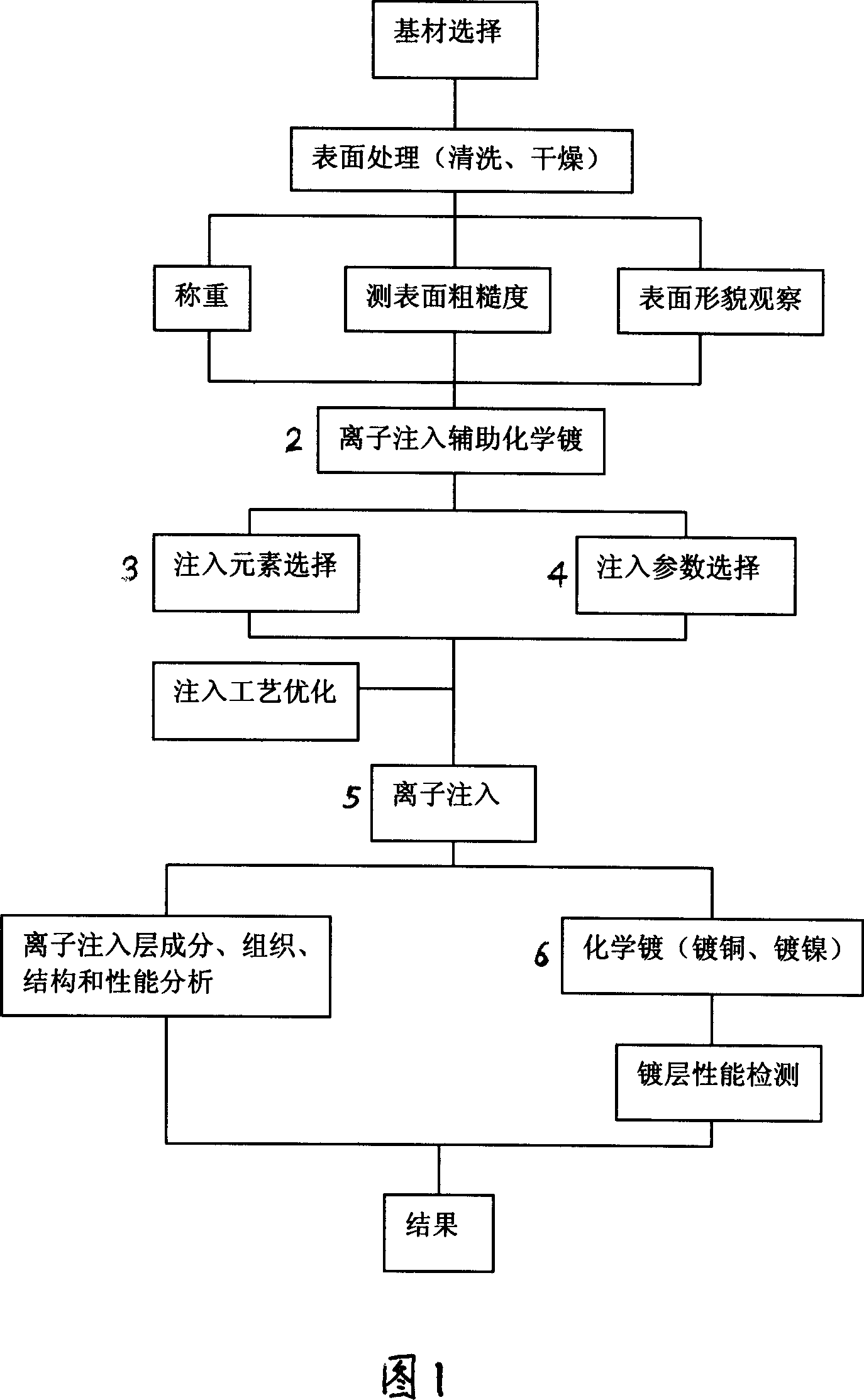

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: select Al for use 2 o 3 Ceramic, Al 2 o 3 Clean the ceramic surface, degrease and remove the dirt attached to the surface; then measure the surface roughness; the prepared ceramics are ion implanted in the ion implantation equipment; the selected ion implantation element is Cu, and the implantation parameters are: implantation energy 17KeV, Injection dose 3.6×10e 17 ions / cm 2 ; Place the injected ceramics in the electroless plating solution for direct electroless copper plating. The electroless copper plating is a conventional electroless copper plating process in the prior art, omitted.

[0027] Combining the two technologies of ion implantation and electroless plating, ion implantation is used to replace the existing chemical pretreatment process in the sense of electroless plating to complete the plating of the metal film on the ceramic surface. The ion implantation equipment is a multifunctional ion implantation enhancement equipment, which is a ...

Embodiment 3

[0029] Example 3: The element selected for ion implantation is copper, and the range of implantation parameters is: implantation energy 10KeV, implantation dose 4.2×10e 17 ions / cm 2 ; The injected ceramics are placed in the electroless plating solution for direct electroless iron plating. Others are the same as embodiment 1, omitted.

Embodiment 4

[0030] Example 4: The element selected for ion implantation is nickel, and the range of implantation parameters is: implantation energy 10KeV, implantation dose 4.2×10e 17 ions / cm 2 ; The injected ceramics are placed in the electroless plating solution for direct electroless iron plating. Others are the same as embodiment 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com