Medical degradable polyester asymmetric membrane and preparation method thereof

A technology for degrading polyester and asymmetric membranes, applied in medical science, surgery, etc., can solve the problems of high production cost, easy mutual peeling, low connectivity rate between pores, etc., and achieves short production cycle, low production cost, and simple process. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 0.1 g of L-polylactic acid PLLA with a number average molecular weight of 500,000 in 10 ml of methylene chloride to form a polymer solution. Weigh 0.5g of sodium carbonate (50-300μm) and mix it with the prepared polymer solution. After stirring evenly, perform ultrasonic defoaming treatment (1000Hz, 5min), and pour the solution into a polytetrafluoroethylene mold (4cm×8cm×0.5cm ), then sink the mold into a container containing 0.1N hydrochloric acid solution, keep it at about 4°C for about 1 hour, remove the mold in water, take out the film, rinse with running water, soak the film in distilled water until silver nitrate detects that there is no precipitation in the water, Freeze-dry to obtain PLLA asymmetric barrier membrane.

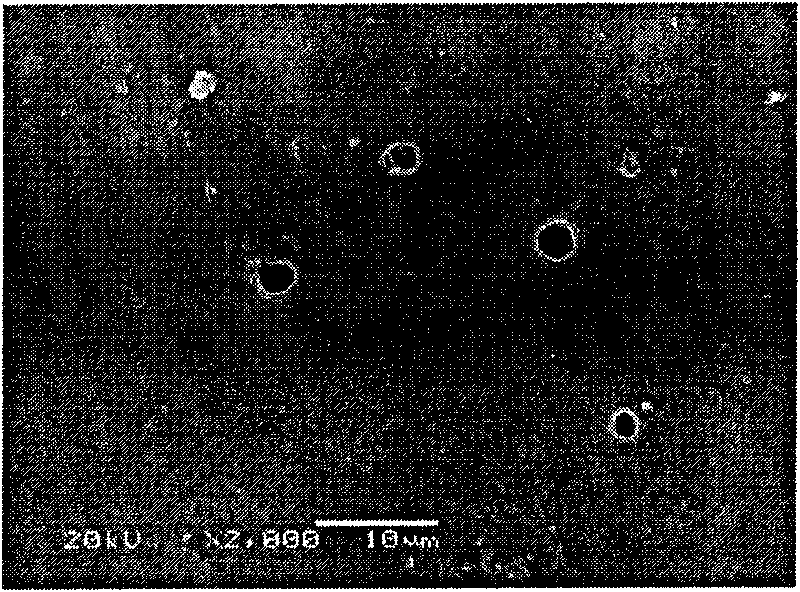

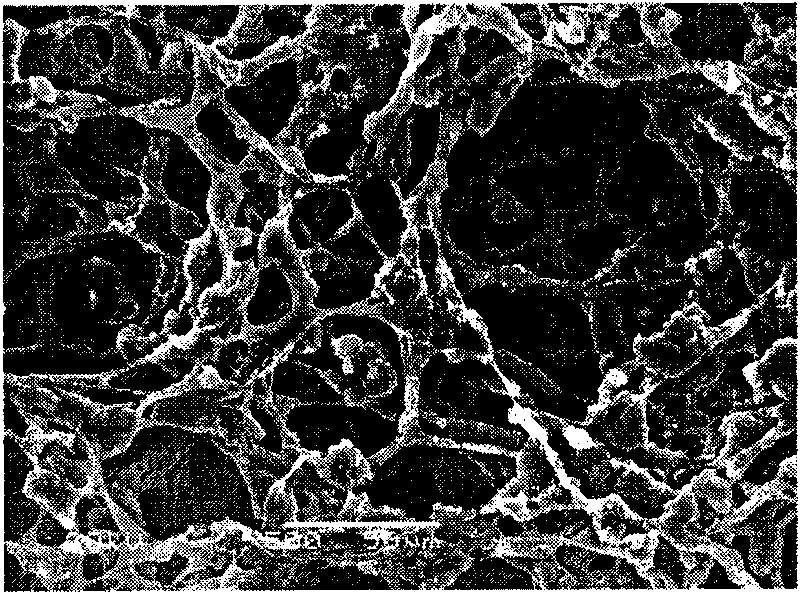

[0025] According to the scanning electron microscope, the average thickness of the film is 0.45mm, and the dense layer has micropores with a pore size of 0.5-5μm; the porous layer has a pore size of 50-300μm, and the pores are connected ...

Embodiment 2

[0027] Dissolve 2.5 g of D, L-type polylactic acid PDLLA with a number average molecular weight of 50,000 in 10 ml of chloroform to form a polymer solution. Weigh 10g of ammonium bicarbonate (50-600μm) and mix it with the prepared polymer solution. After stirring evenly, perform ultrasonic defoaming treatment (500Hz, 10min), and pour the solution into a polytetrafluoroethylene mold (4cm×8cm×0.5cm ), then submerge the mold into a container filled with distilled water, keep it at about 100°C for about 12 minutes, remove the mold in water, take out the film, rinse with running water, soak the film in distilled water until neutral, and freeze-dry to obtain the PDLLA asymmetric barrier film.

[0028] According to the scanning electron microscope, the average thickness of the membrane is 0.6mm, and the dense layer has micropores with a pore diameter of 0.5-5μm; the porous layer has a pore diameter of 50-600μm, and the pores are connected to each other; the membrane is soft and can be...

Embodiment 3

[0030] 1.0 g of PGA with a number average molecular weight of 100,000 was dissolved in 10 ml of N,N-dimethylformamide to form a polymer solution. Weigh 5g of ammonium carbonate (50-600μm) and mix it with the prepared polymer solution. After stirring evenly, perform ultrasonic defoaming treatment (1000Hz, 3min), and pour the solution into a polytetrafluoroethylene mold (4cm×8cm×0.5cm) Then submerge the mold into a container filled with distilled water, keep it at about 75°C for about 15 minutes, remove the mold in water, take out the film, rinse with running water, soak the film in distilled water until neutral, and freeze-dry to obtain the PGA asymmetric barrier film .

[0031] According to the scanning electron microscope, the average thickness of the film is 0.5mm. The dense layer has micropores with a pore size of 0.5-5μm; the porous layer has a pore size of 50-600μm, and the pores are connected to each other; The elongation rate is 5-8%, and the shape remains unchanged fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com