Novel method for modifying graphene with polymer

A graphene and polymer technology, applied in the field of surface modification and dispersion of graphene, can solve the problems of easy damage, weakened transmission, unstable composite structure, etc., and achieves the effect of strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

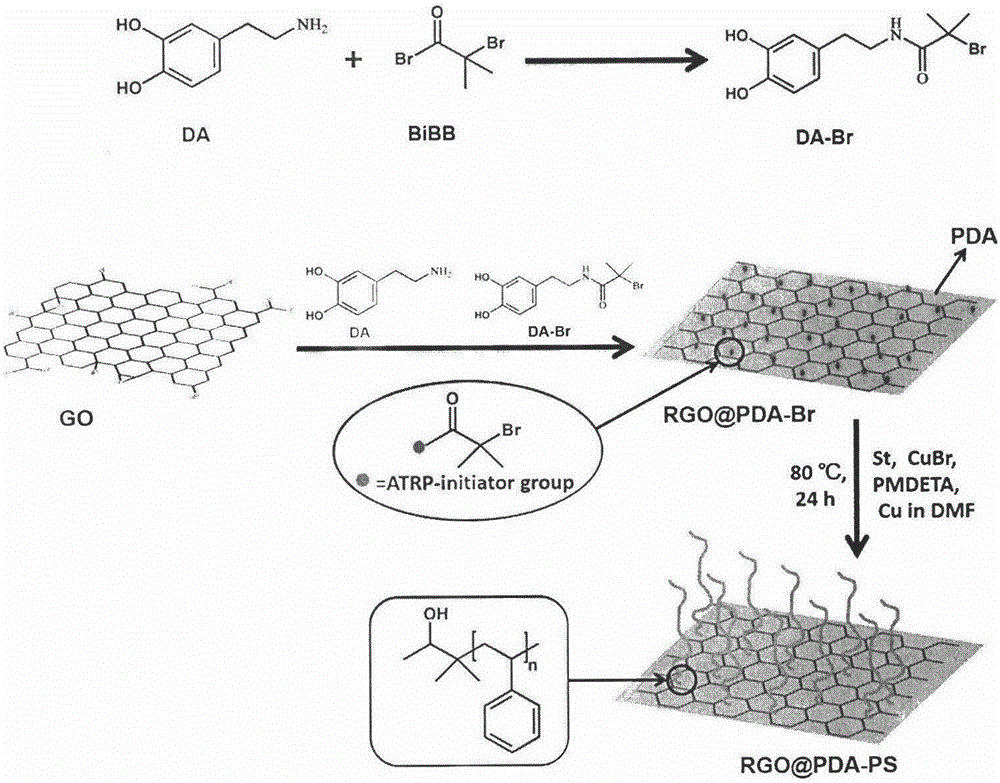

[0022] The first step is to weigh 0.4g dopamine (DA) and dissolve it in 10mL DMF, and add 2-bromo-2-methylpropionyl bromide (BiBB) and triethylamine (TEA) in an equimolar amount to BiBB, and the molar ratio of BiBB to dopamine 1:1, through N 2 Oxygen was removed for 15 minutes, and stirred for 12 hours in an ice-water bath.

[0023] The second step is to weigh 0.1g of graphene oxide (GO), add 50mL of water, ultrasonically disperse for 30min, add it into the reaction system, and stir at room temperature for 12h. After the reaction is completed, the product is centrifuged and washed with deionized water until the supernatant is colorless, and the obtained solid is dispersed in deionized water again, and freeze-dried to obtain the macromolecular initiator RGOPDA-Br.

[0024] The third step is to dissolve 40 mg of initiator RGOPDA-Br in 4 mL of DMF and ultrasonically disperse for 1 h, add 4 mL of styrene (St), 110 μL of initiator ligand N, N, N', N, 'N"-pentamethyldiethylene Bas...

Embodiment 2

[0026] In the first step, weigh 0.4g DA and dissolve it in 10mL DMF, add BiBB and TEA in an equimolar amount to BiBB, the molar ratio of BiBB to DA is 2:1, pass N 2 Oxygen was removed for 15 minutes, and stirred for 12 hours in an ice-water bath.

[0027] The second step is to weigh 0.1gGO, add 50mL water, ultrasonically disperse for 30min, add it to the reaction system, and stir at room temperature for 12h. After the reaction is completed, the product is centrifuged and washed with deionized water until the supernatant is colorless, and the obtained solid is dispersed in deionized water again, and freeze-dried to obtain the macromolecular initiator RGOPDA-Br.

[0028] The third step is to dissolve 40 mg of initiator RGOPDA-Br in 4 mL of DMF and ultrasonically disperse for 1 h, add 4 mL of St, 110 μL of initiator ligand PMDETA, 30 mg of CuBr, and copper wire, remove water and oxygen in the system by freezing and thawing pump circulation, and place React in an oil bath at 90°C...

Embodiment 3

[0030] In the first step, weigh 0.4g DA and dissolve it in 10mL DMF, add BiBB and TEA in an equimolar amount to BiBB, the molar ratio of BiBB to DA is 2:1, pass N 2 Oxygen was removed for 15 minutes, and stirred for 12 hours in an ice-water bath.

[0031] The second step is to weigh 0.1gGO, add 50mL water, ultrasonically disperse for 30min, add it to the reaction system, and stir at room temperature for 12h. After the reaction is completed, the product is centrifuged and washed with deionized water until the supernatant is colorless, and the obtained solid is dispersed in deionized water again, and freeze-dried to obtain the macromolecular initiator RGOPDA-Br.

[0032] The third step is to dissolve 40mg of initiator RGOPDA-Br in 4mL of DMF and ultrasonically disperse for 1h, add 4mL of tert-butyl acrylate (tBA), 110μL of initiator ligand PMDETA, 30mg of CuBr, and copper wire, and remove it from the system by freezing and thawing pump circulation. water and oxygen, placed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com