Multi-layer structure with internal embedded circuit and non-contact laser processing method thereof

A laser processing method and multi-layer structure technology, applied in metal processing equipment, laser welding equipment, welding equipment, etc., can solve problems such as large deformation of stamps, difficulty in micro-electrode transfer alignment, electrode fracture, etc., to reduce process costs , to avoid the effect of difficult microelectrode alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

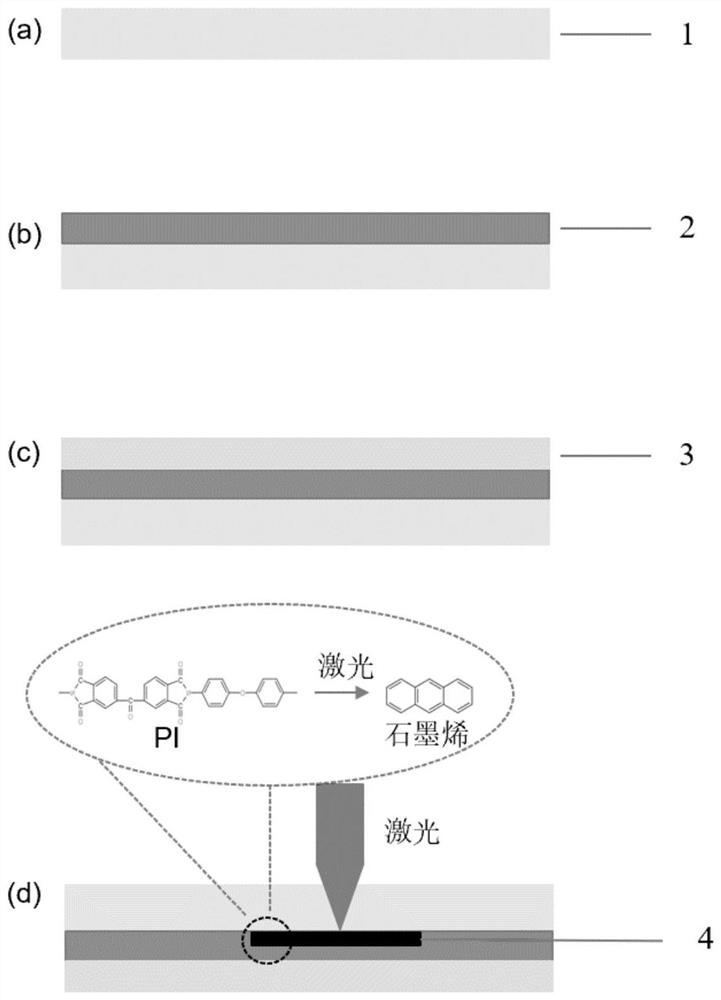

[0038] The preparation method for preparing a composite film of a multilayer interconnected conductive circuit (abbreviated as a composite film of a multilayer interconnected conductive circuit) comprises the following steps:

[0039] First, a light-absorbing polymer layer is prepared on a substrate in the manner described above to obtain a two-layer structure; then, a mask having a single hole is attached to the surface of a two-layer light-absorbing polymer layer, and After depositing a layer of light-absorbing polymer material on the film, the mask is removed to ensure that only the position corresponding to the single hole is deposited with light-absorbing polymer material, and then cured to form a light-absorbing polymer connecting column. Next, prepare an encapsulation layer on the surface of the light-absorbing polymer layer on which the light-absorbing polymer connection posts are formed (the encapsulation layer mainly plays the role of bonding the upper and lower two-l...

Embodiment 1

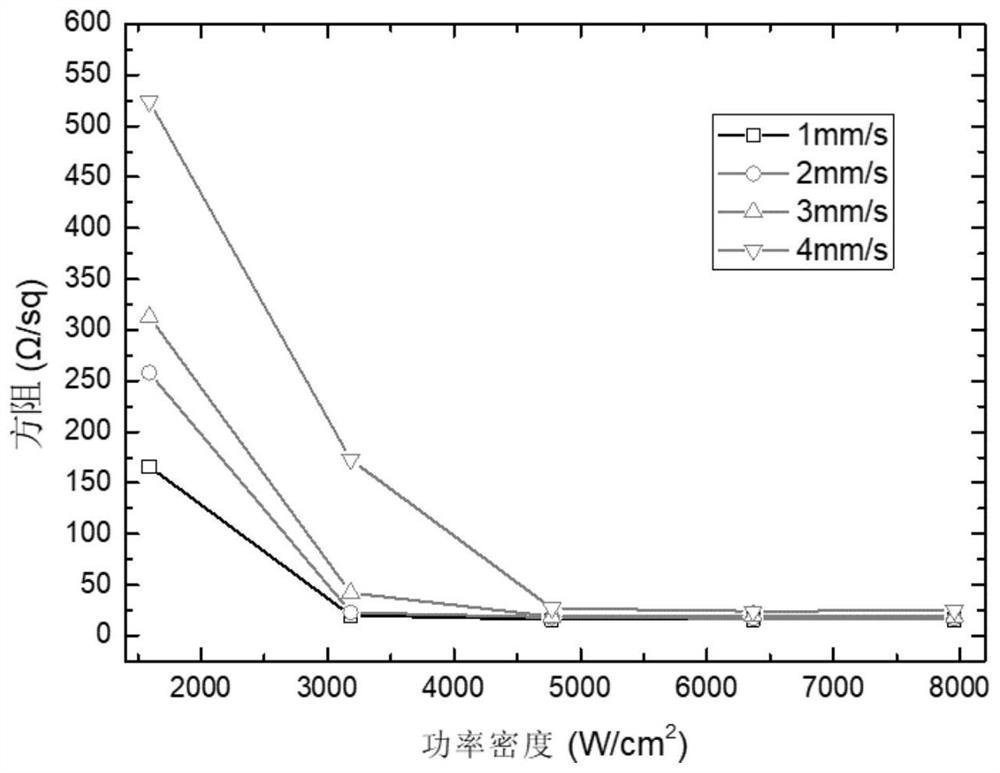

[0050] For a single-layer strain sensor, first spin-coat a layer of PI on the cleaned quartz glass sheet and place two thin wires on the edge, and then continue to use the spin-coating process on the obtained quartz glass / The surface of the PI film is then spin-coated with a layer of epoxy resin film; after that, the obtained film sample is placed on the XY motion platform of the laser test bench, and the height and horizontal position of the XY motion platform are adjusted so that the laser spot is located at the center of the film sample. At the position of one of the thin wires, the two ends of the laser scanning pattern overlap with the two thin wires; then, adjust the energy density and scanning speed of the laser, and the laser irradiates the light-absorbing polymer inside the interlayer through the laser transparent substrate material on the top On the surface, the irradiated polymer will absorb the energy of photons to undergo photothermal or photochemical decompositio...

Embodiment 2

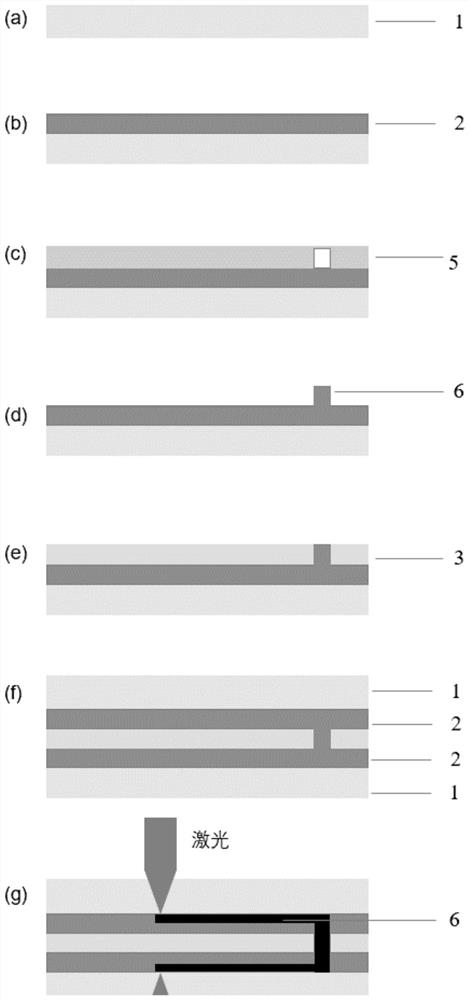

[0059] see figure 2 , the laser processing method of the multilayer structure embedded with multilayer interconnected planar inductors and planar capacitors provided by Embodiment 2 of the present invention mainly includes the following steps:

[0060] (1) Adopting the method in the laser embedded processing single-layer patterned conductive circuit step (1) to clean the quartz glass and the method of spin coating in the step (2) to prepare two samples of quartz glass / PI;

[0061] (2) Paste a mask with a single hole on the PI surface of one of the samples, spin coat a layer of PI on the surface, tear off the mask to ensure that only the single hole contains PI, and then cure to obtain light-absorbing polymerization Connect column 6.

[0062] (3) Prepare epoxy resin by the method in step (3) of laser embedded processing single-layer patterned conductive circuit, then spin-coat a layer of epoxy resin on the surface of quartz glass / PI sample, and prepare in step (1) Another piec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com