Device for polishing and cooling plastic tapes from gas nozzles

A plastic belt and slot technology, applied in the field of plastic belts, can solve the problems of inapplicability to manufacture plastic films with high transparency, good cooling effect, inapplicability, etc., and achieve good calendering effect, outstanding cooling effect, and good film characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

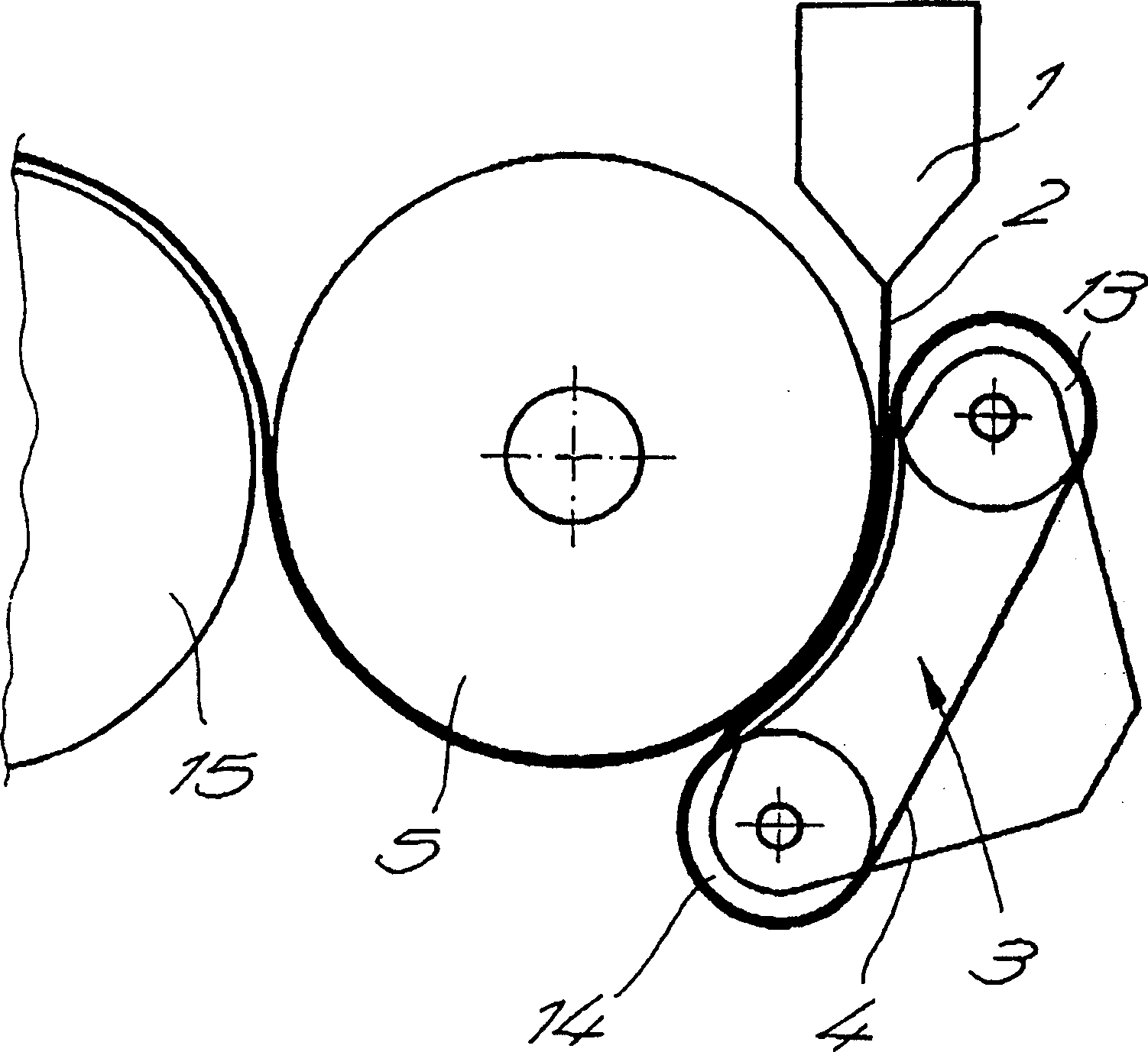

[0020] figure 1 A device known from the prior art is shown in . In this case, the plastic strip 2 emerging from the slot nozzle 1 is guided through a calendering device 3 . The calendering unit 3 comprises a chilled calender roll 5 and an endless belt 4'. The endless belt 4 ′ rests against the plastic belt 2 along a part of the circumference of the calender roll 5 . To cool the endless belt 4 ′ or the plastic belt 2 , the endless belt 4 ′ is guided by cooling rollers 13 , 14 . Furthermore, the plastic strip 2 emerging from the calendering nip and the cooling nip between the calendering roll 5 and the endless belt 4' embraces the calendering roll 5 and is then guided through another calendering nip where it passes through the calendering roll 5 Formed between another cooling calender roll 15.

[0021] The cooling effect achieved with known devices is not entirely satisfactory. The endless belt 4 ′ is first cooled on cooling rollers 13 before it comes into contact with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com