All hydraulic subarea controllable middle-high super plating press

A super calender, full hydraulic technology, applied in the direction of calender, paper machine, textile and paper making, etc., can solve the problems of damage to calender roller, reduce production efficiency, affect equipment work, etc., achieve fast and stable braking, The effect of reducing production cost and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

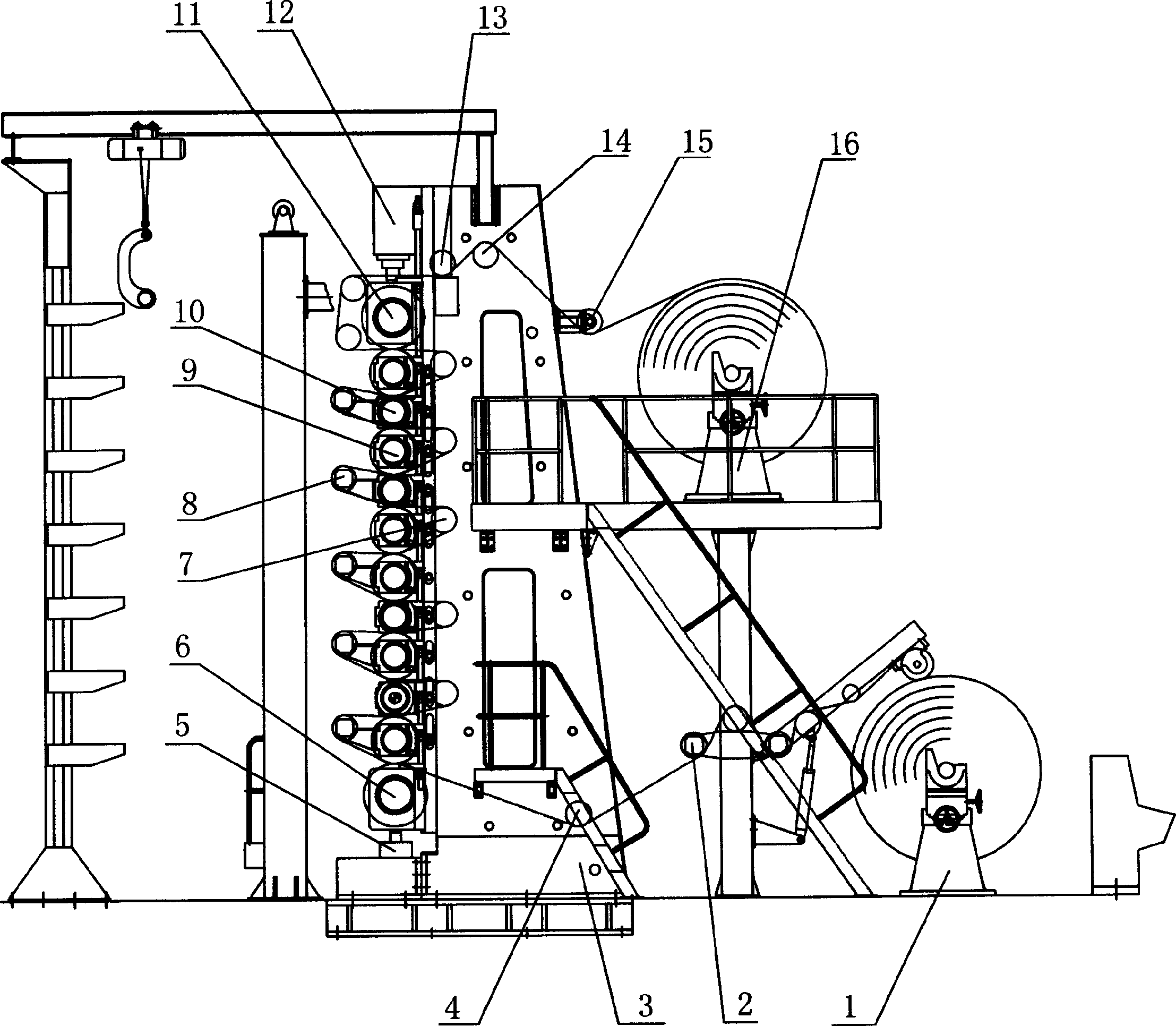

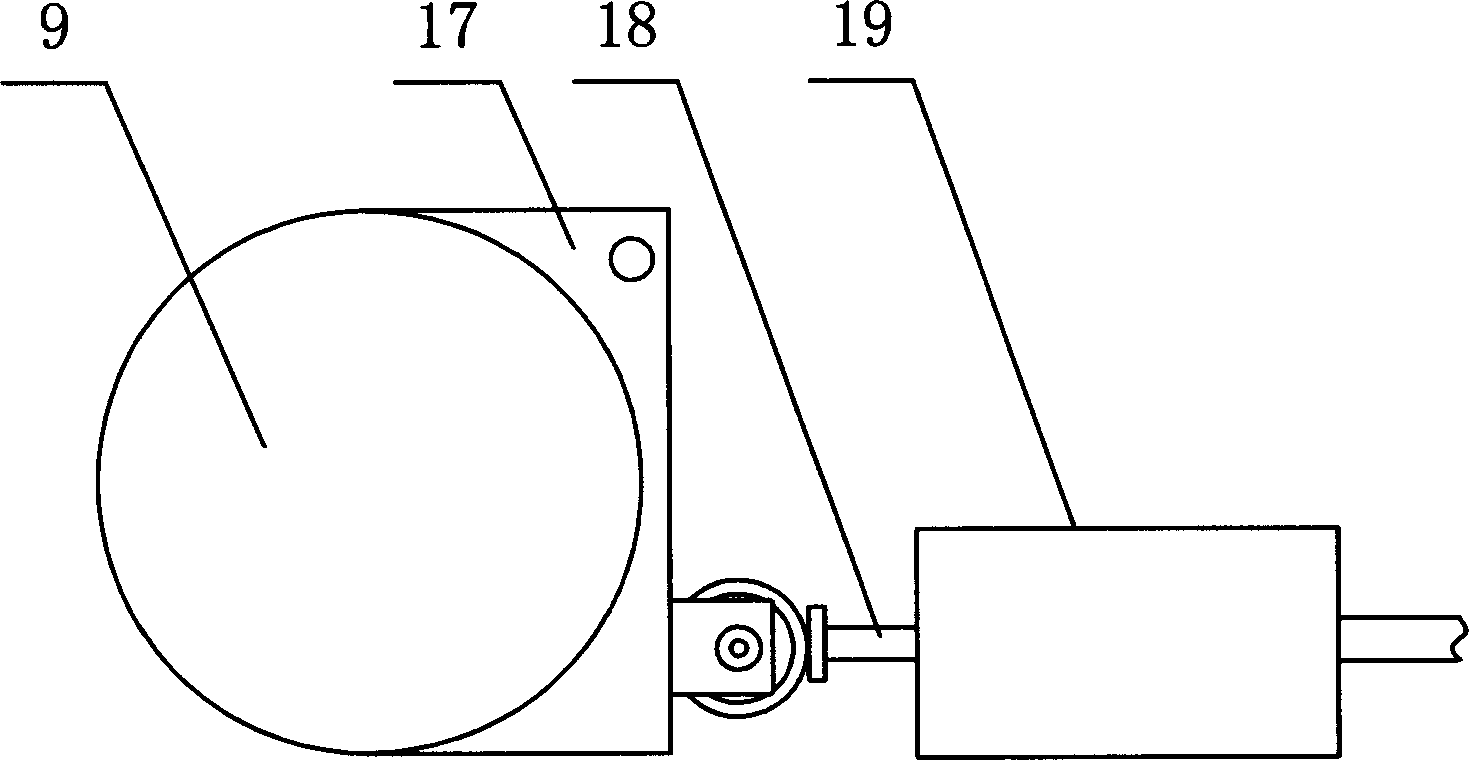

[0017] Such as figure 1 As shown, the reel of the semi-finished paper to be calendered is placed on the support 16, and the rollers are slowly rotated according to the normal procedure of the prior art, and the paper is slowly fed into the roller through the guide rollers 15, 14 and 13 in turn. Between the pressure rollers, and from top to bottom in order to pass through between the pressure rollers, and finally the paper is rolled onto the winding drum through the guide rollers 4 and 2 arranged in front of the winding drum. After the rewinding reel completes the rewinding work to the paper, it is controlled and started by the master control device provided outside the frame 3 respectively. figure 2 As shown, the hydraulic cylinder 19 fixed on the frame 3 works, and the hydraulic cylinder 19 works to push the push block 17 hinged on the frame and matched with the calender roll 9 through the push rod 18, and the push block 17 then pushes the calender roll 9 Move up, so that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com