Large steel structure lifting method and large steel structure lifting apparatus

A lifting device and steel structure technology, applied to cranes and other directions, can solve problems such as poor carrying capacity, danger, and difficulty in unloading, and achieve the effects of reduced section size, reasonable force, and ingenious angle design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

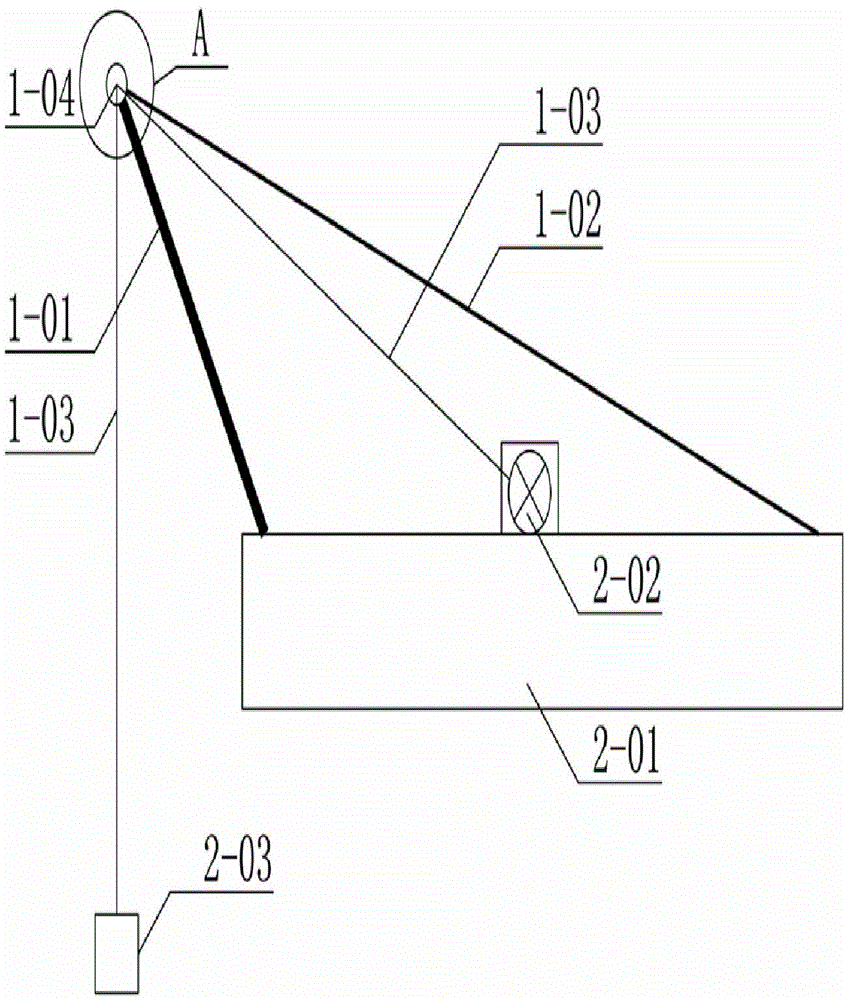

[0058] Example 1: as Figure 5 and Image 6 As shown, it is a non-retractable boom, including a boom 5-01, the lower end of which is hinged on the high-level floor 5-06, and a pneumatic cylinder 5-02, one end of which is hinged on the high-level floor 5-06, and the other end is hinged on the ceiling Bottom boom 5-01, the upper end of the boom 5-01 is connected to the sling 5-03 through a pulley, and the lower end of the sling is tied to the item 5-040 The ordinary boom is supported by a pneumatic cylinder, and the boom is lifted up by the pneumatic cylinder Realize the horizontal movement of goods. like Figure 5 As shown, the pneumatic cylinder is generally connected to the middle or one-third of the boom, and the distance between the connection position of the pneumatic cylinder and the support and the connection position of the boom and the support is generally one-third of the boom. ] When the cargo is 2 tons, it is known through force analysis and calculation that the ...

example 2

[0059] Example 2: as Figure 7 and Figure 8 As shown, it is another non-retractable boom, including a boom 5-01, which is fixed on the high-level floor 5-06 through two supports, and the other end extends out of the floor to form a hoisting end, and the suspending rope 5 is connected through a pulley. -03 Lift cargo 5-04. When lifting the goods for unloading, it is necessary to use manpower to pull the goods to the unloading platform 5-05.

[0060] When the weight is still 2 tons, the calculated manpower varies greatly with the length of the sling and the position of the person. The manpower is about 3kN to 8.5kN, which is equivalent to an equivalent mass of 306kg to 867kg.

example 3

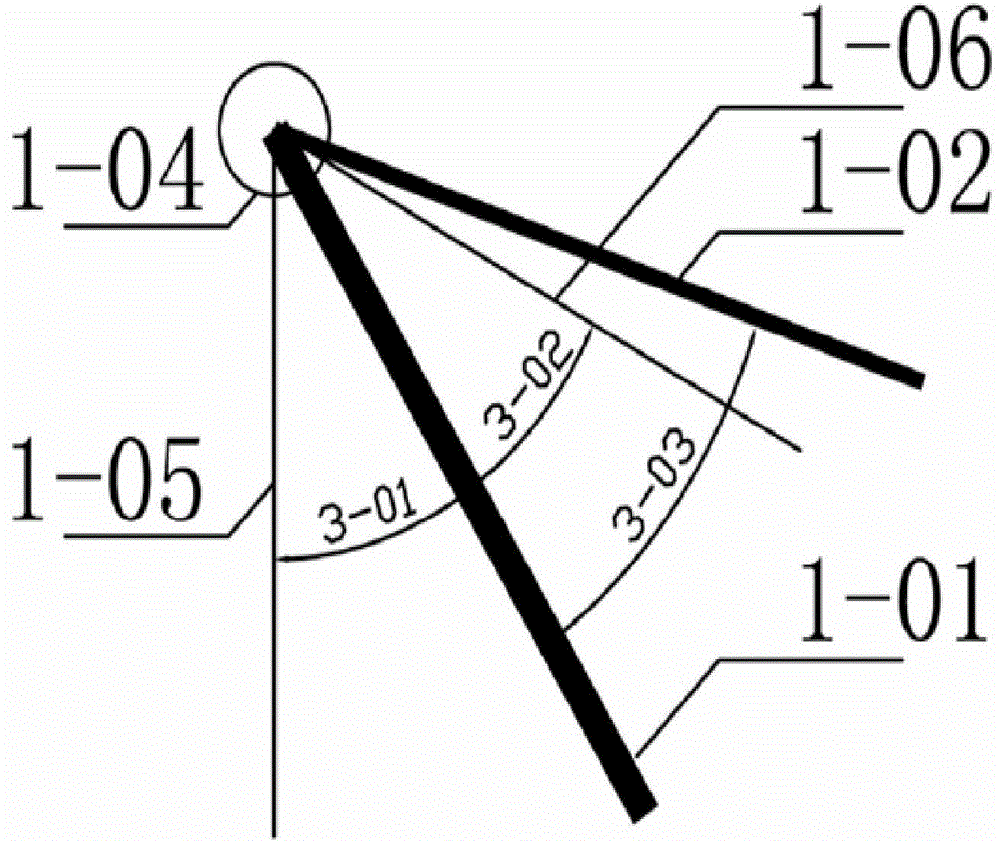

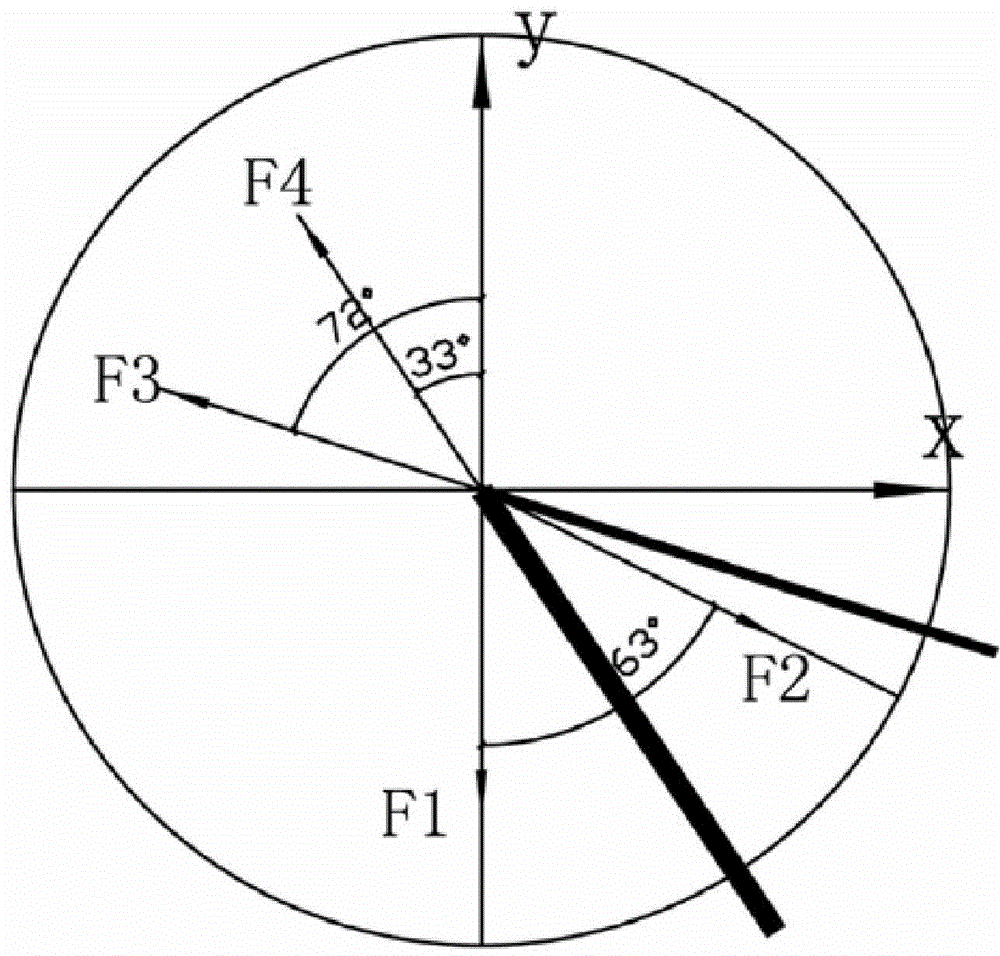

[0061] Example 3: Using the hoisting device provided by the present invention in the context of the project, using the hoisting method provided by the present invention, such as Figure 9 and Figure 10 As shown in the figure, after lifting the cargo, a vertical force is applied on the wind rope 1-02. Through any method and mechanical calculation, the axial force on the wind rope is about 1 / 40-1 / 10 compared with the gravity of the goods, while When the vertical force is applied to the wind rope, it can be calculated by mechanical method that the vertical force is about 10 / 1-1 / 5 of the axial force of the wind rope.

[0062] ] By calculation, when the weight of the cargo is 2 tons, the axial force of the wind rope is about 0.26kN, and the load applied by the person is 0.06kN, which is equivalent to 6.1kg.

[0063] It can be seen from the above three examples that the lifting weight is both 2 tons. The external force required for unloading in Example 1 is 45kN, and the equivalen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com