316L stainless steel and preparation method thereof

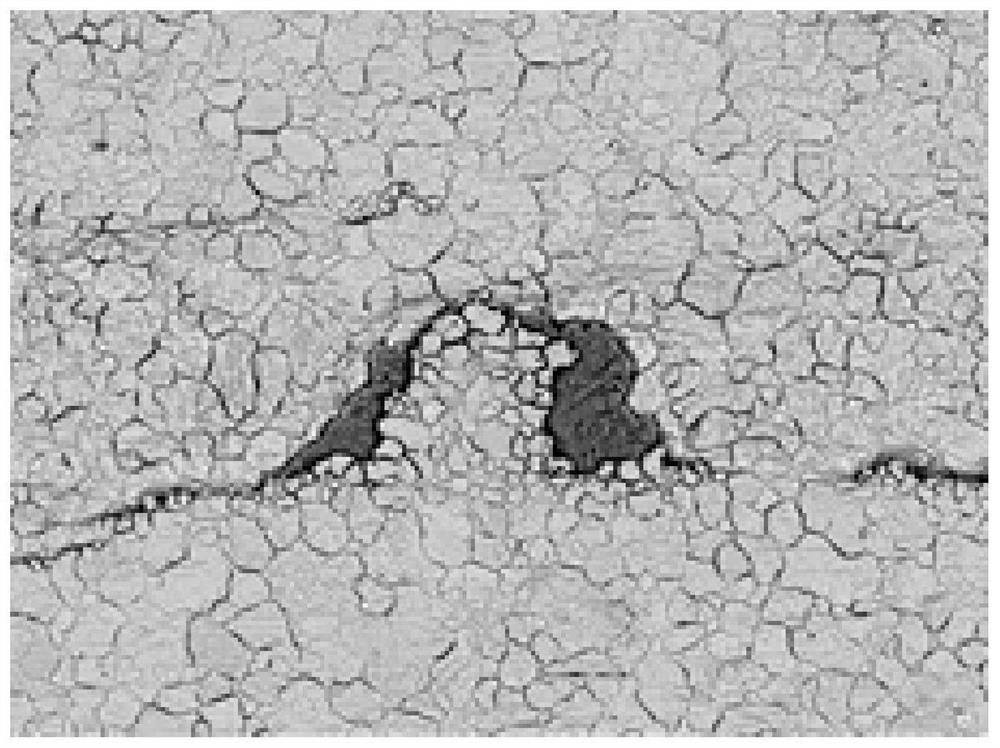

A technology of stainless steel and tons of steel, which is applied in the field of preparation of 316L stainless steel, can solve the problems of stainless steel plasticity decline, cracks, increase, etc., and achieve the effect of improving high temperature plasticity and calendering performance, low alkalinity, and ensuring desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

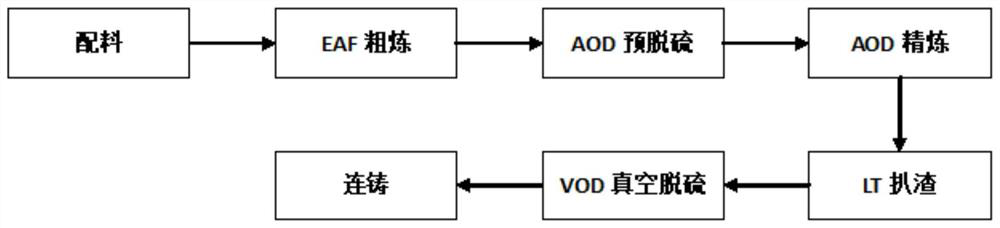

[0033] This embodiment provides a kind of 316L stainless steel, which is prepared through the following steps, and the specific process is as follows figure 1 Shown:

[0034] The temperature of the EAF soup (EAF raw materials are generally waste stainless steel, ferrochrome, nickel cold wash, lime) is 1540°C. After the molten soup is loaded into the transfer ladle, it enters the slag removal station for slag removal. After the slag removal is complete, the molten soup is loaded into the AOD refining furnace body.

[0035] After the start of AOD refining, pre-desulfurization treatment is carried out first, fluorite: 4kg / ton of steel is added in sequence, lime is added in batches of 3 times: a total of 20kg / ton of steel, silicon carbide: 5kg / ton of steel, bottom blowing and stirring for 20 minutes, pre- After the desulfurization is completed, S≤500ppm, reduce the desulfurization pressure in the later stage of AOD.

[0036] After the AOD pre-desulfurization treatment, oxygen bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com