Portable ultrasonic calendering tool

A calendering knife, portable technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment and other directions, can solve the problems of large damage to the guide rail of the machine tool transmission mechanism, damage to the accuracy and life of the machine tool, and difficulty in mastering the rolling process. , to achieve the effect of easy replacement of the calendering head, saving coolant, and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

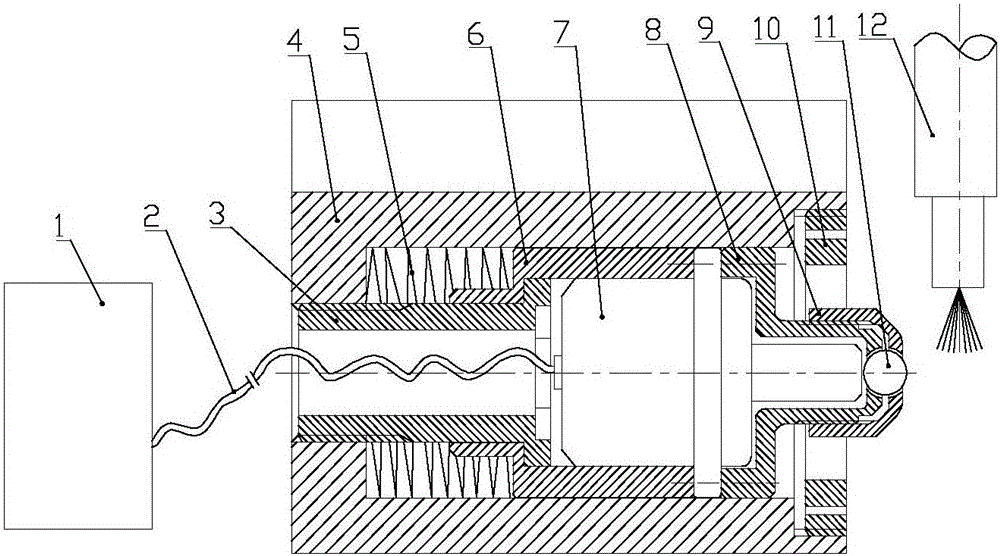

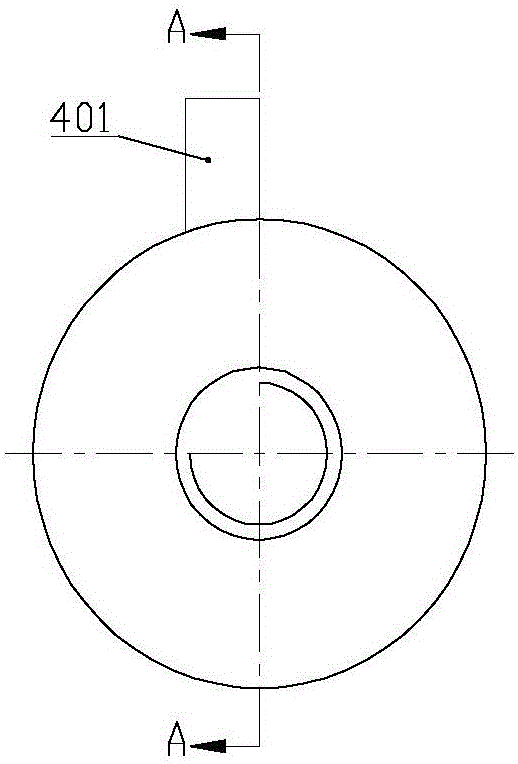

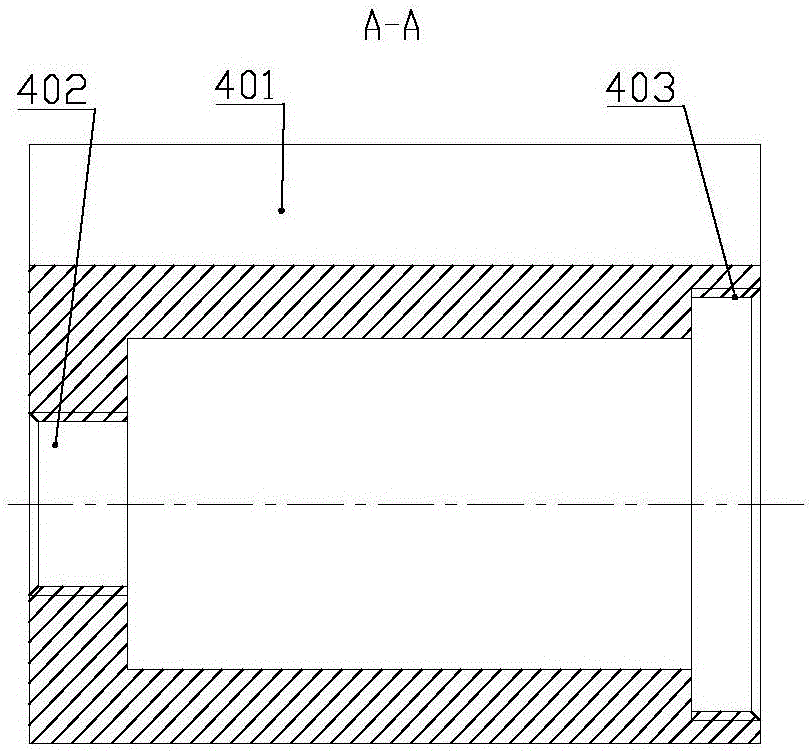

[0026] Such as Figure 1 to Figure 3 , Image 6 , Figure 7 As shown, the portable ultrasonic calender includes an outer sleeve 4, an inner sleeve 6, an ultrasonic transducer 7, a rolling element 11, and an oil mist lubrication device 12. The outer sleeve 4 and the inner sleeve 6 are cylindrical cylinders with one end open, and the outer wall of the outer sleeve 4 A clamping block 401 is provided on the upper part of the outer sleeve 4, a threaded hole 402 is provided at the center of the bottom of the cylinder body; the inner sleeve 6 is provided with a central hole at the center of the cylinder bottom, and the inner sleeve 6 is placed in the outer sleeve 4 with the open end facing outwards. There is a gap between the outer circumference and the inner wall of the cylindrical cavity of the outer sleeve 4. A spring 5 is arranged between the bottom of the outer sleeve 4 and the bottom of the inner sleeve 6; the inner sleeve 6 is placed in the outer sleeve 4 to form an elastic expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com