Calendering film coating machine for multifunctional fabric

A multi-functional film coating machine technology, applied in the processing of textile materials, fabric surface trimming, and processing of textile material carriers, etc., can solve the problems of poor adhesion of functional coatings, cumbersome procedures, time-consuming and labor-intensive processes, etc., to ensure adhesion and process Simple, Adhesive Improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

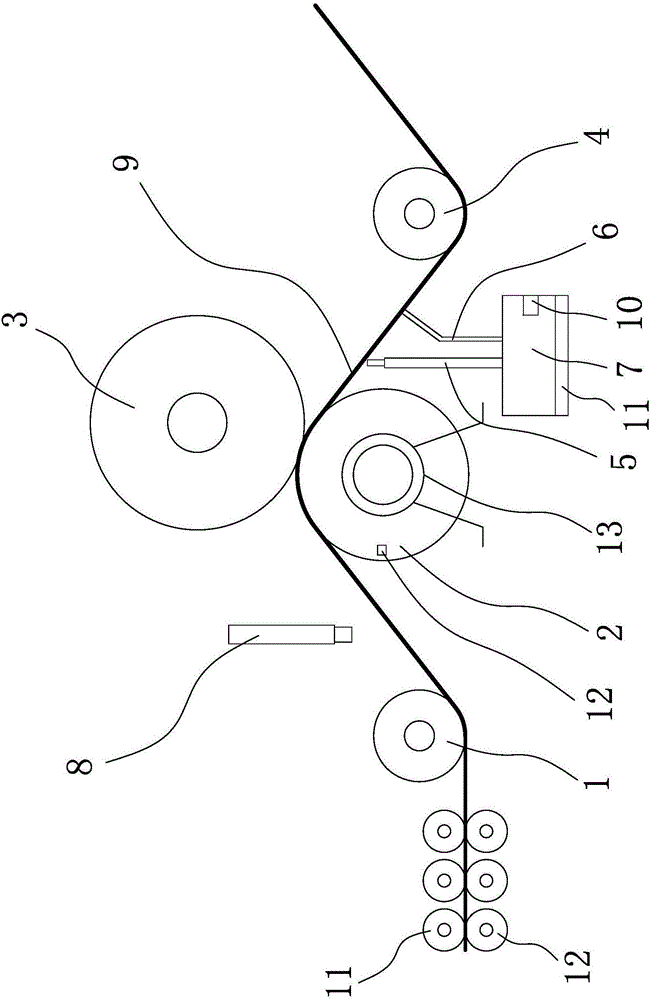

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0021] refer to figure 1 , the present embodiment is a calender coating machine for multi-functional fabrics, comprising a cloth feeding roller 1, a hard hot roller 2, a soft rolling roller 3, a cloth discharging roller 4, a hot blower 7, and several pairs of The upper pressing roller 11 and the lower pressing roller 12 are set, the hard hot roller 2 is made of metal material, and the hard hot roller 2 has an electric heater built in, the soft roller 3 is made of plastic or rubber, the cloth feeding roller 1 and the cloth outlet Roller 4 is respectively positioned at the both sides of hard hot roll 2, and soft roll 3 is positioned at the top of hard hot roll 2 or leans to the oblique top of one side of cloth outlet roll 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com