Production process of myopia prevention paper

A production process and anti-myopia technology, which is applied in the field of papermaking, can solve the problems of large environmental pollution of anti-myopia paper, and achieve the effects of saving costs, reducing the amount of addition, and preventing myopia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

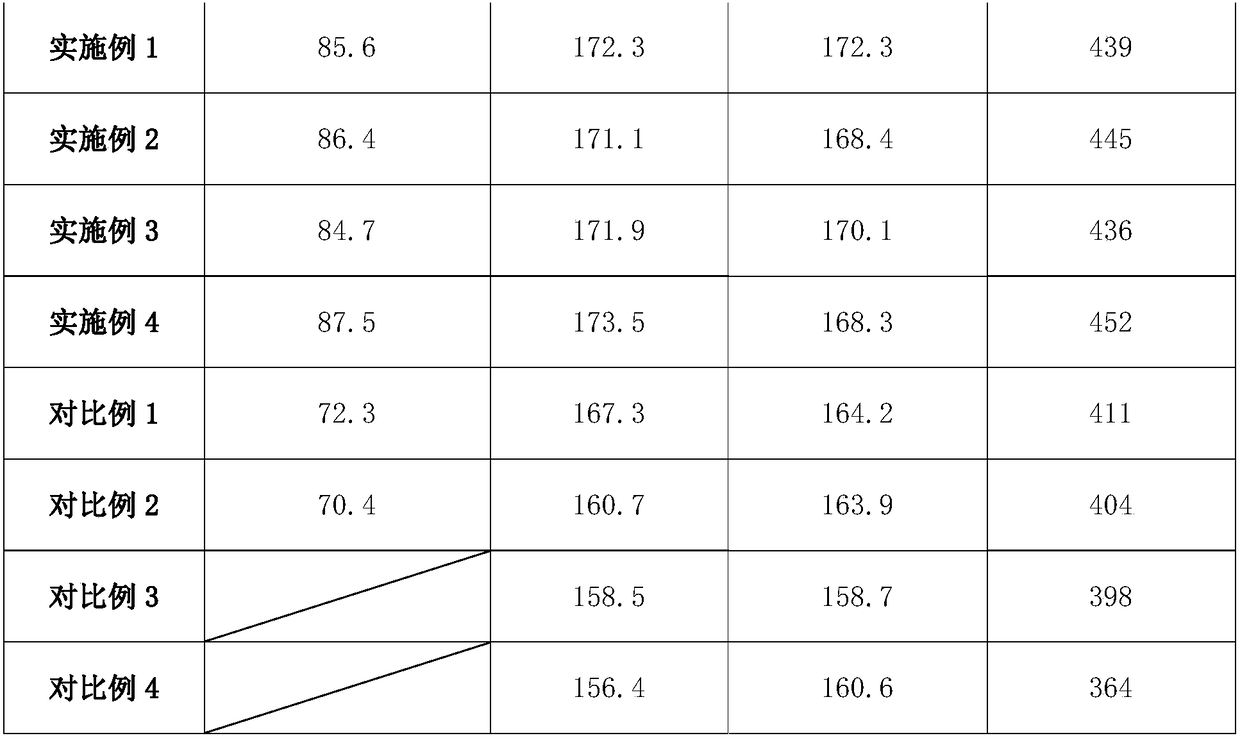

Embodiment 1

[0031] This embodiment discloses a production process of anti-myopia paper, comprising the following steps:

[0032] (1) Prepare the following raw materials in mass parts: 29 parts of rice straw, 16 parts of reed, 12 parts of mulberry bark, 38 parts of Cizhu, 4.2 parts of boric acid, 8 parts of sizing agent, 3.6 parts of silicon micropowder, 5.3 parts of talcum powder, 6 parts of earth, 0.12 parts of magnesium oxide, 0.02 parts of magnesium hydroxide, 1.5 parts of aluminum hydroxide, and 7.5 parts of phosphoric acid.

[0033](2) Preparation of slurry: select the stalks of straw and reed, tie them into water and soak them in water, take them out when the grass color changes from yellow to light yellow, then soak them in milk of lime, and steam them for 10 hours; take them out and wash away the residual alkali, then The first slurry is obtained by mechanical pulping. Cut mulberry bark and Cizhu into wood blocks with a thickness of 0.45 cm, and then soak them in 10% sodium hypoc...

Embodiment 2

[0041] This embodiment discloses a production process of anti-myopia paper, comprising the following steps:

[0042] (1) Prepare the following raw materials in parts by mass: 31 parts of straw, 19 parts of reed, 14 parts of mulberry bark, 39 parts of Cizhu, 4.9 parts of boric acid, 9 parts of sizing agent, 4 parts of silicon micropowder, 6.4 parts of talcum powder, 7 parts of earth, 0.18 parts of magnesium oxide, 0.025 parts of magnesium hydroxide, 1.7 parts of aluminum hydroxide, and 8 parts of phosphoric acid.

[0043] (2) Preparation of slurry: select the stalks of straw and reed, tie them into water and soak them in water, take them out when the grass color changes from yellow to light yellow, then soak them in milk of lime, and steam them for 10 hours; take them out and wash away the residual alkali, then The first slurry is obtained by mechanical pulping. Cut mulberry bark and Cizhu into wood blocks with a thickness of 0.5 cm, and then soak them in a 12% sodium hypochlo...

Embodiment 3

[0051] This embodiment discloses a production process of anti-myopia paper, comprising the following steps:

[0052] (1) Prepare the following raw materials in parts by mass: 34 parts of straw, 23 parts of reed, 15 parts of mulberry bark, 44 parts of Cizhu, 5.4 parts of boric acid, 9 parts of sizing agent, 4.2 parts of silicon micropowder, 8 parts of talcum powder, 8 parts of earth, 0.28 parts of magnesium oxide, 0.03 parts of magnesium hydroxide, 1.9 parts of aluminum hydroxide, and 9 parts of phosphoric acid.

[0053] (2) Preparation of slurry: select the stalks of straw and reed, tie them into water and soak them in water, take them out when the grass color changes from yellow to light yellow, then soak them in milk of lime and steam them for 11 hours; take them out and wash away the residual alkali, then The first slurry is obtained by mechanical pulping. Cut mulberry bark and Cizhu into wood blocks with a thickness of 0.6 cm, and then soak them in 14% sodium hypochlorite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com