Shoe lining production process

A production process and technology for shoe linings, which are applied in the fields of biochemical fiber treatment, bleaching products, textiles and papermaking, etc., can solve the problems of affecting the grade and price of shoes, short service life of shoe linings, and low stiffness of shoe linings, and achieve calendering. Good effect, stable size, not easy to degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

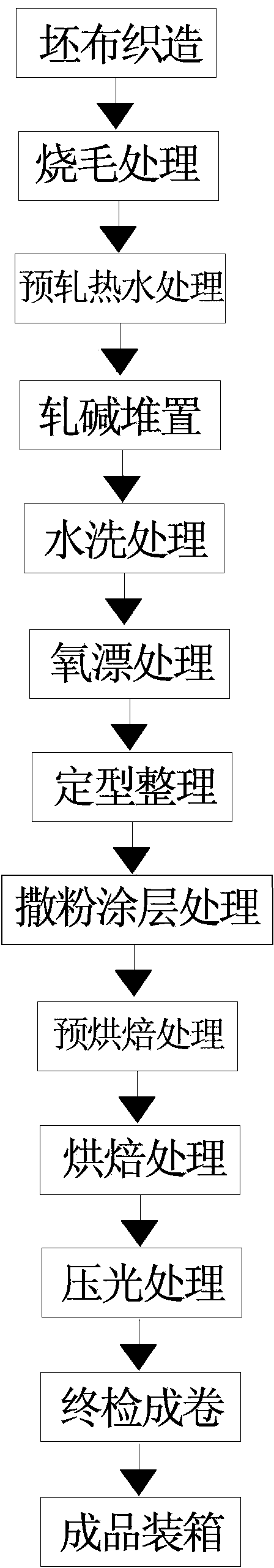

[0028] refer to figure 1 , a kind of shoe liner production process of the present invention, comprises the following steps successively:

[0029] A) Gray fabric weaving: The warp and weft yarns of the woven base fabric are 28Tex×28Tex cotton yarns woven on a rapier loom with 228 threads / 10cm×236 threads / 10cm to form shoe lining gray fabric;

[0030] B) singeing treatment: singeing the shoe lining gray cloth, the temperature is 57 ° C;

[0031] C) pre-rolling hot water treatment: the padding hot water treatment is performed on the shoe lining gray cloth that has undergone B) singeing treatment, and the temperature of the padding hot water is 63 ° C;

[0032] D) Alkali rolling and stacking: the shoe lining gray cloth that has completed C) pre-rolling hot water treatment is treated with light lye (NaOH) by padding, and then stacked for 2.7 hours;

[0033] E) washing treatment: carry out desizing and washing to the shoe liner gray cloth that finished D) rolling and alkali stacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com