Controllable crown roll

A medium and high roller, the same technology, applied in the field of controllable medium and high rollers, can solve the problems of increasing processing costs, affecting work efficiency, inconvenient maintenance, etc., and achieve the effect of reducing the difficulty of maintenance, good supporting effect and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

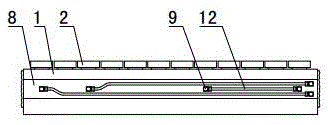

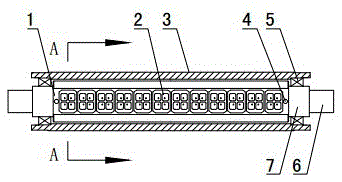

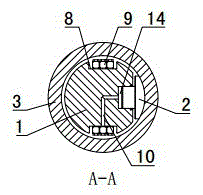

[0032] Figure 1~7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~7 The present invention will be further described.

[0033] A controllable mid-height roll, comprising a mandrel 1 and a cylinder 3 rotatably sleeved outside the mandrel 1, a plurality of static pressure supporting pistons 2 are arranged at intervals on the mandrel 1, and an oil discharge hole 4 is provided on the mandrel 1 , the side of the mandrel 1 is provided with an accommodating groove 8, and an oil inlet hole 10 communicating with the static pressure support piston 2 is opened in the accommodating groove 8, and a transition hole 13 communicating with the end face of the mandrel 1 is opened, and the accommodating groove 8 An oil pipe 12 connecting the transition hole 13 and the oil inlet hole 10 is provided. The side of the mandrel 1 of the controllable middle-high roller is provided with an accommodating groove 8, and the accommodating groove 8 is respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com