Handle-free frame type solid wood composite kitchen cabinet door sheet and manufacturing method thereof

A technology of solid wood composite and solid wood panels, which is applied in the direction of door leaves, windows/doors, manufacturing tools, etc., can solve problems such as cracking of door panels, achieve the effects of preventing glue overflow, saving paint costs, and saving wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

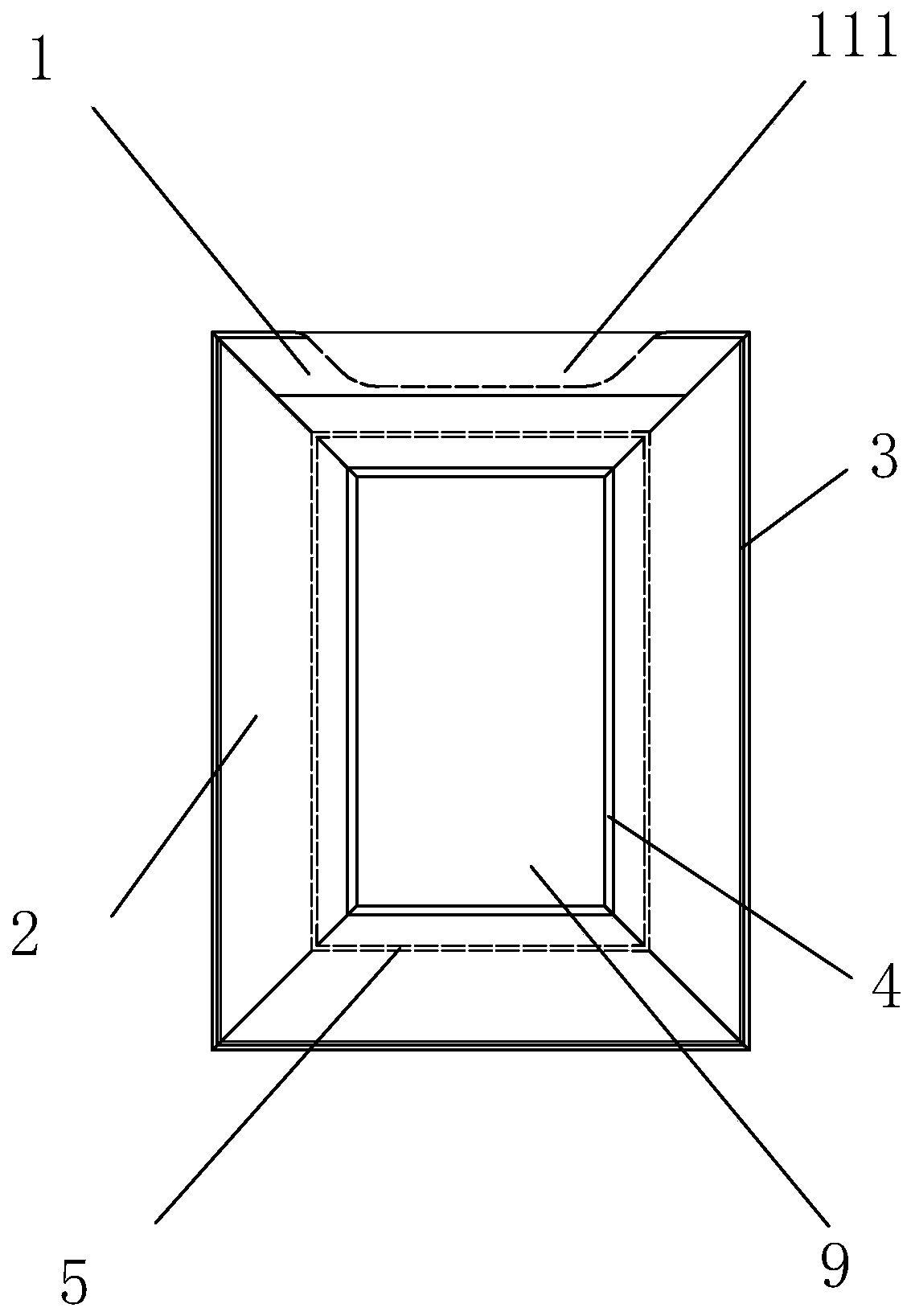

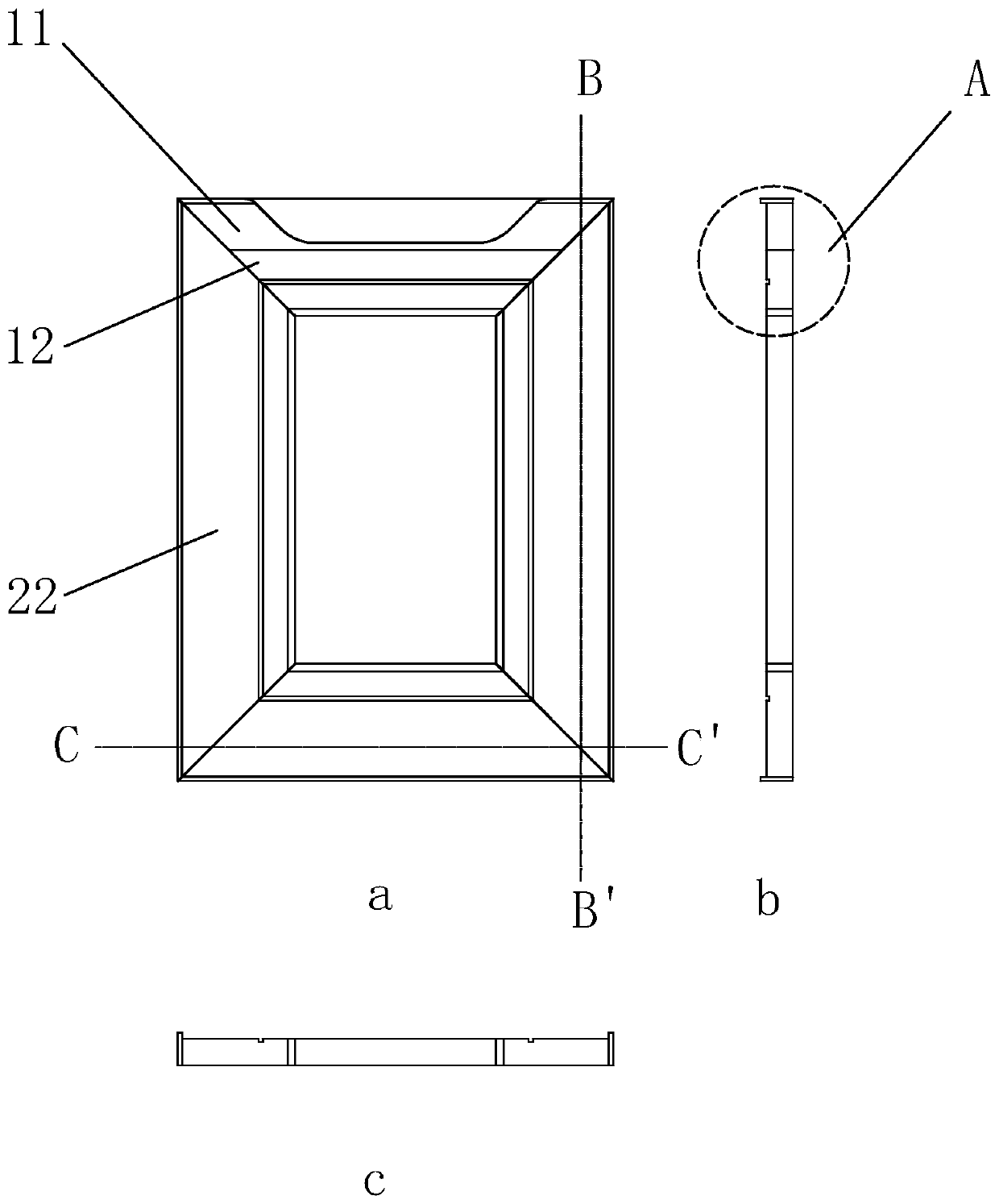

[0042] like Figures 1 to 8 , a handle-free frame type solid wood composite kitchen cabinet door panel of this embodiment includes a door frame and a door core panel 9, the door frame is attached to the door core panel 9; the door core panel 9 includes glass, acrylic, anti-folding Special, slate material.

[0043] The door frame is formed by splicing four frames. The frame in this embodiment is a 45° oblique frame, the two ends of the frame are respectively provided with tenons 61 and mortise 62, and the four frames are spliced by a tenon structure. In order to ensure the stability of the frame, glue is applied to the splicing part, the tenon 61 is provided with a thread 63 , and the mortice 62 is provided with a convex ring matching the thread 63 .

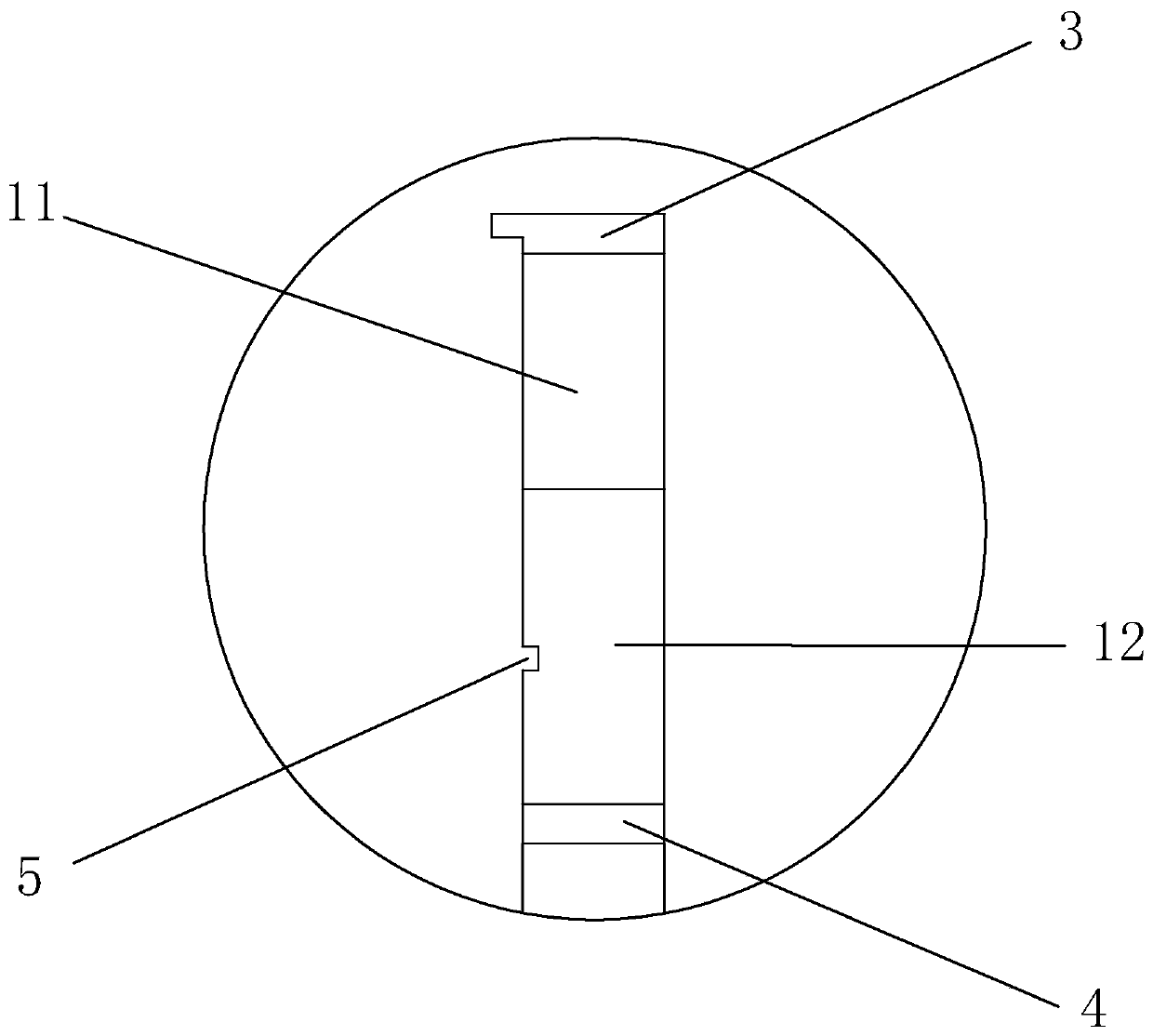

[0044] The frame includes a handle frame 1 arranged on the top, and three non-handle frames 2 arranged on the left, right and bottom; the handle frame 1 includes a solid wood slat 11 and a first multi-layer board substrate 12,...

Embodiment 2

[0062] like Figure 9 and Figure 10 , a handle-free frame type solid wood composite kitchen cabinet door panel of this embodiment includes a door frame and a door core panel 9, and the door frame is attached to the door core panel 9;

[0063] The door frame includes a handle frame 1 and a multi-layer board 8; the handle frame 1 includes a solid wood slat 11, and the solid wood slat 11 is provided with a handle shape 111; one side of the multi-layer board 8 is connected to the solid wood slat 11. Splicing, and the exposed outer side of the multi-layer board 8 is covered with an outer solid wood edge strip 3, and the outer solid wood edge strip 3 covers the frame and the side wall of the door core board 9 at the same time; the door core board 9 is provided with The groove 91 that the handle shape 111 is adapted to.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com