Method and device for after-finishing of various textiles and non woven fabrics through plasma treatment technology

A technology of textile fabrics and non-woven fabrics, applied in the direction of ultrasonic/sonic fiber treatment, etc., can solve the problems of affecting quality, color fading and degumming, etc., and achieve the effects of not easy degumming, improving color fastness, and coating equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

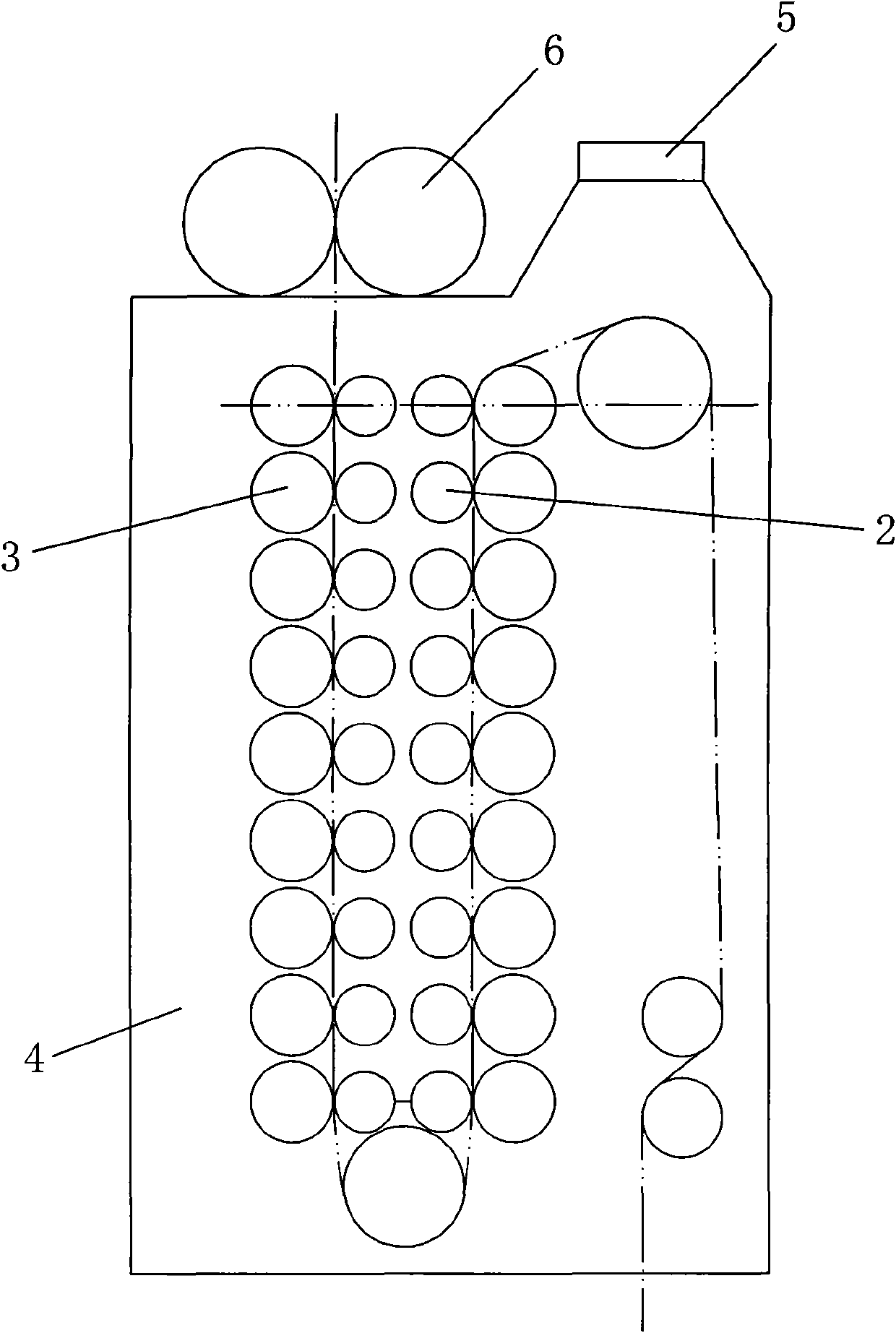

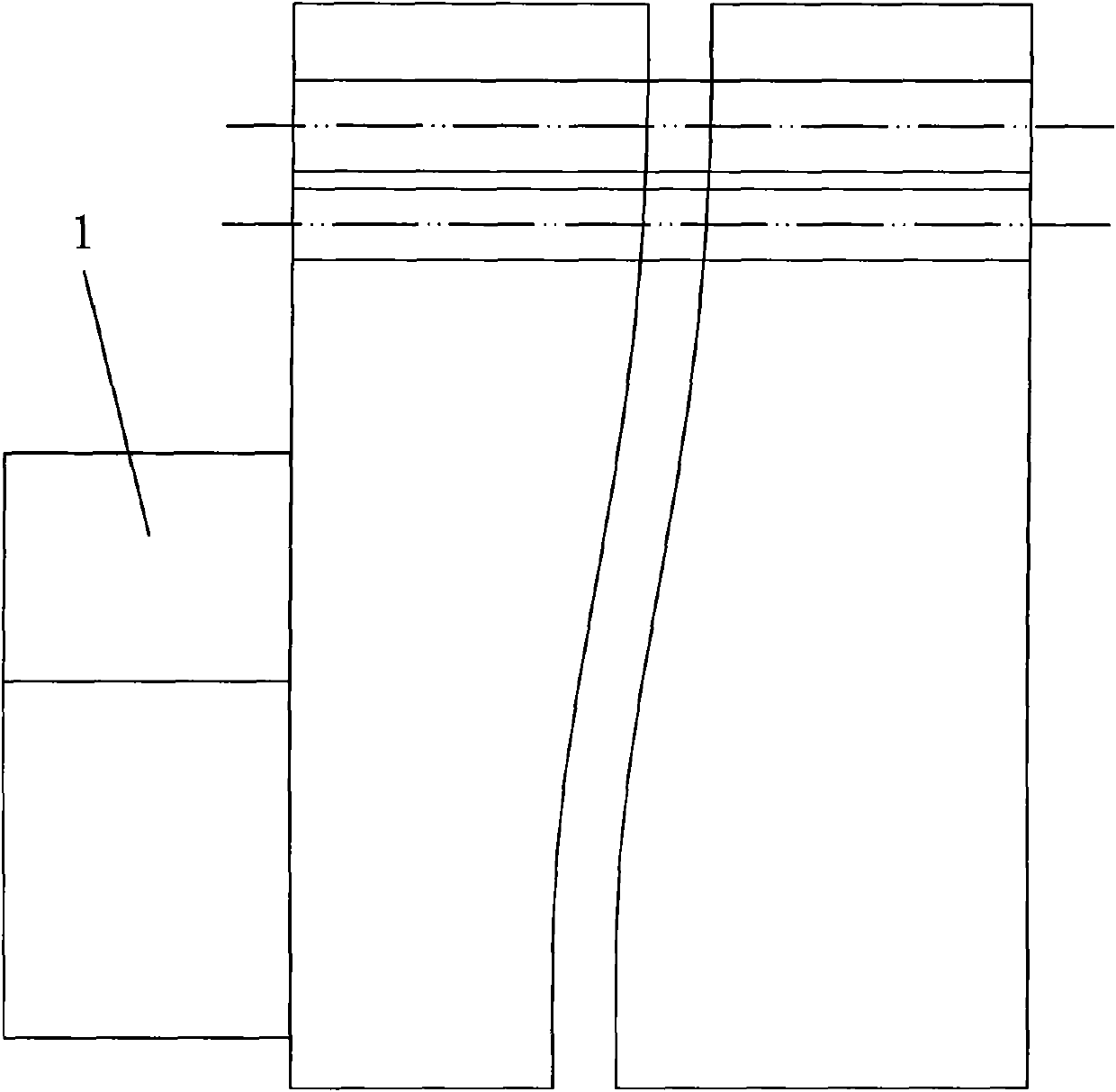

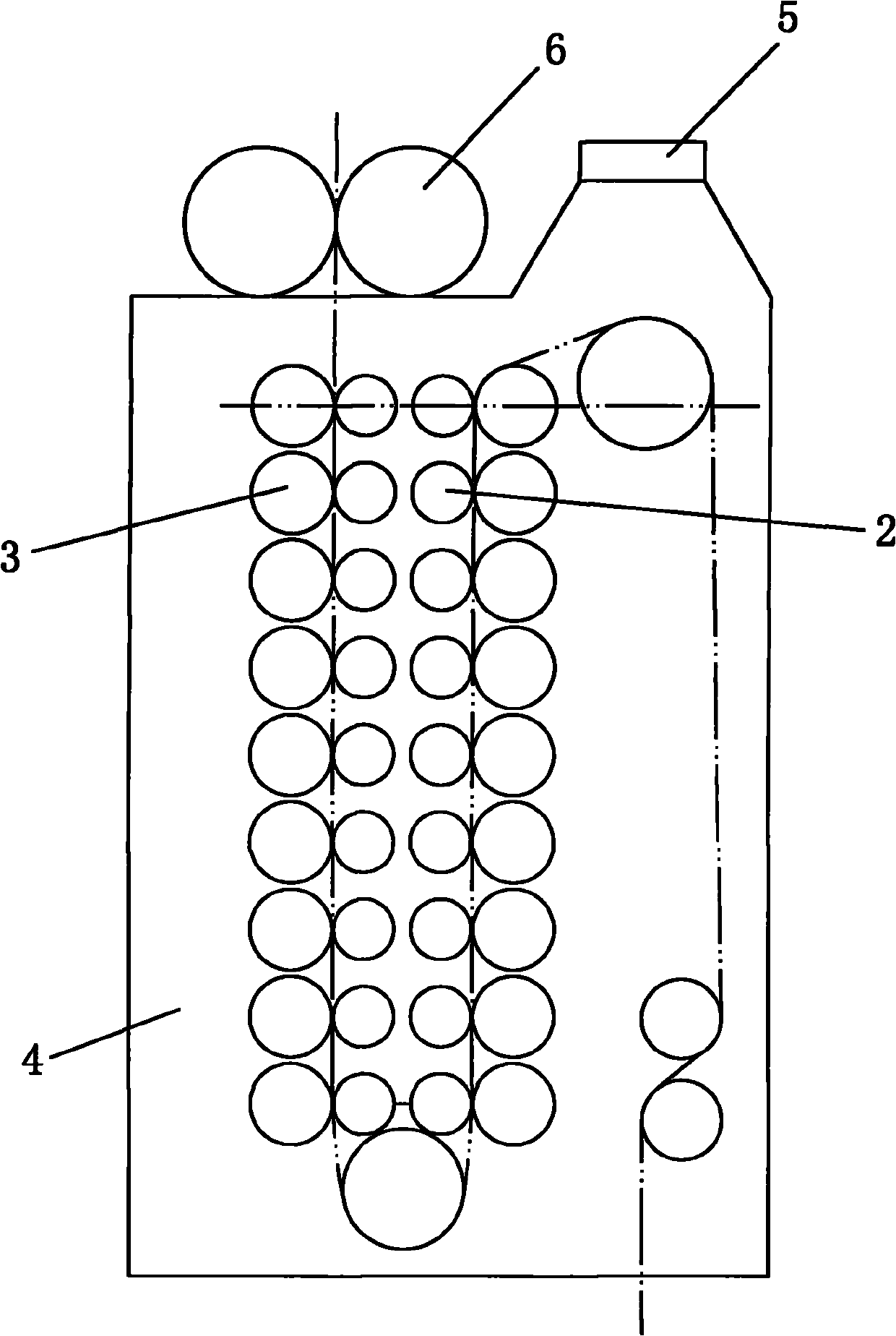

[0014] like figure 1 The equipment for the plasma treatment technology of various textile fabrics and non-woven fabrics shown includes an electric control box 1 connected to the outside, and the electric control box 1 controls a plasma generator discharge channel 2 to various textile fabrics. And non-woven fabrics for discharge treatment. Roller rotating electrodes 3 are arranged on both sides of the discharge channel 2 of the plasma generator. The roller rotating electrodes 3 are fixed on a frame 4 that can be equipped with a suspension bridge to form a set of processing systems. An ozone absorber 5 and a set of clamping rollers 6 are also connected above the discharge channel 2 of the plasma generator.

[0015] The method of plasma treatment technology for finishing various textile fabrics and non-woven fabrics is as follows: various textile fabrics and non-woven fabrics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com