Vibration damping composite rubber mat plate used under railway rail and preparation method thereof

A technology of composite rubber and railway rails, which is applied in the field of rubber sheets, can solve the problems of easy falling off, poor adhesion between stainless steel sheets and rubber sheets, etc., and achieve the effects of good bonding, aesthetics, and not easy to degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

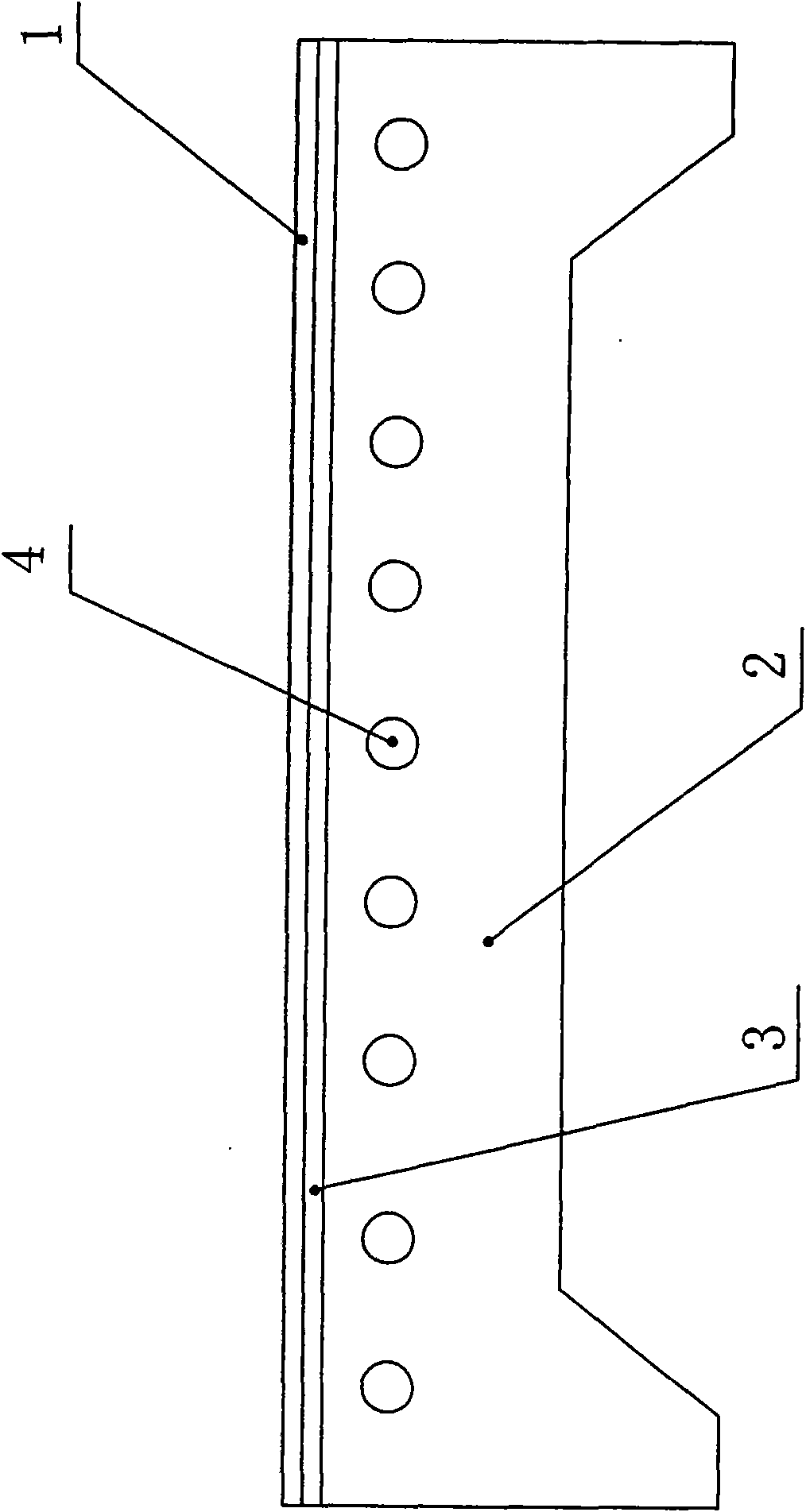

[0020] Such as figure 1 As shown, the present invention welds a reticulated metal plate 3 on the bottom surface of the stainless steel plate 1, and then forms the stainless steel plate 1 and the rubber plate 2, so that the stainless steel plate 1 and the reticulated metal plate 3 are jointly connected to the upper surface of the rubber plate 2 to form Rubber backing. The upper surface of the molded rubber plate 2 can be bonded to the bottom surface of the stainless steel plate 1 through the mesh of the mesh metal plate 3, thereby greatly improving the bonding strength between the stainless steel plate 1 and the rubber plate 2, which cannot be peeled off manually. During the peeling test, the stainless steel plate 1 and the rubber plate 2 were respectively pulled from both sides of the rubber backing plate by external force, the rubber backing plate was pulle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com