Secondary cable carrot joint capable of thermally shrinking directly

A secondary cable and radish head technology, which is applied in the direction of connection/termination cable equipment, connection insulation, etc., can solve the problems of time-consuming winding insulation tape, affecting the overall performance of the cable, and poor sealing, so as to avoid inconsistent or inconsistent appearance. Beautiful, save time, improve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

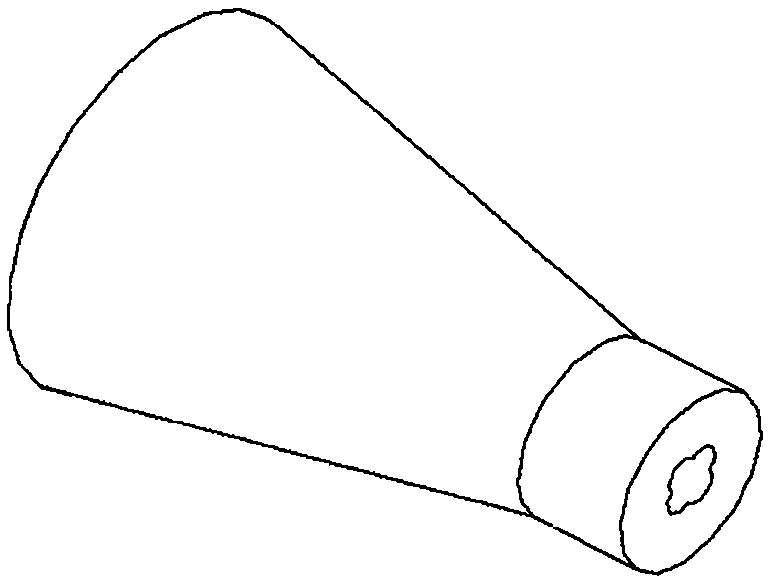

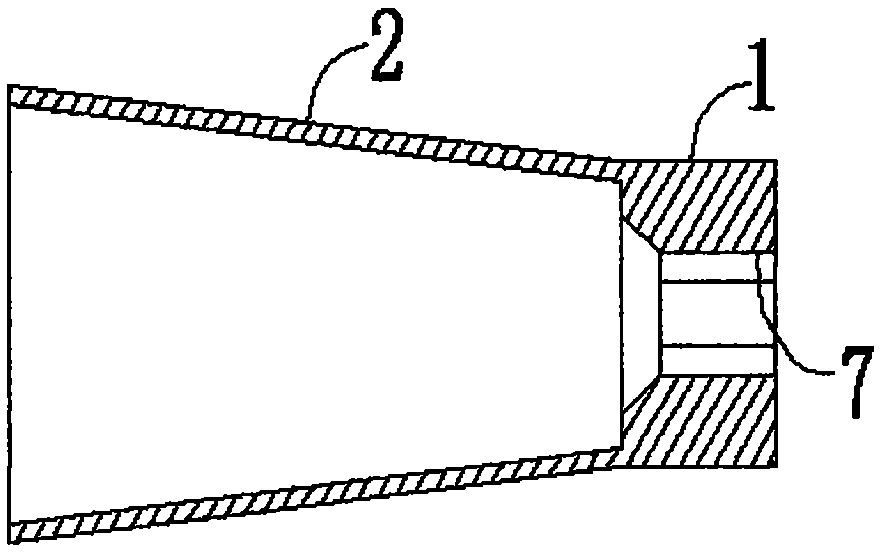

[0022] Such as figure 1 , figure 2 As shown, the present invention provides a direct heat-shrinkable secondary cable radish head, which is characterized in that it includes a radish head main body 1 and a heat-shrinkable sheath 2 .

[0023] Such as figure 2 As shown, the main body 1 of the radish head is cylindrical as a whole, and its central axis is provided with an inlet hole 7, and the inlet side of the inlet hole 7 is provided with an inlet anti-blocking chamfer 6;

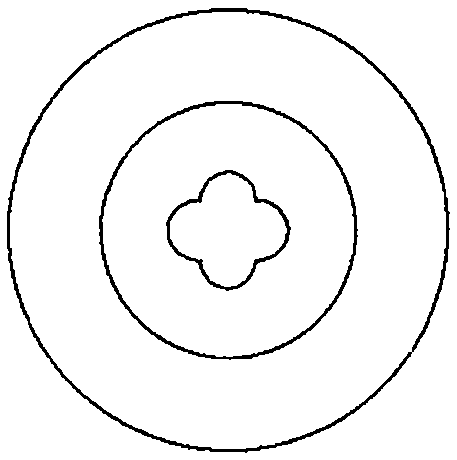

[0024] The shape of the wire inlet hole 7 is corresponding to the outer contour shape of the overall cross-section of the cable core, and the outer dimension of the hole is slightly smaller than the corresponding outer contour dimension of the cable core.

[0025] The heat-shrinkable skirt 2 is made of heat-shrinkable material, which is in the shape of a ring-shaped skirt (that is, in the shape of a vertebral body). One side adjacent to the cable carrot head main body 1 is the skirt waist, and the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com