PLA composite fiber filament and making process and application thereof

A composite fiber and manufacturing process technology, which is applied in the field of composite fiber filaments, can solve the problems of easy breakage and poor flexibility, and achieve the effects of not easy breakage, strong flexibility, and obvious cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

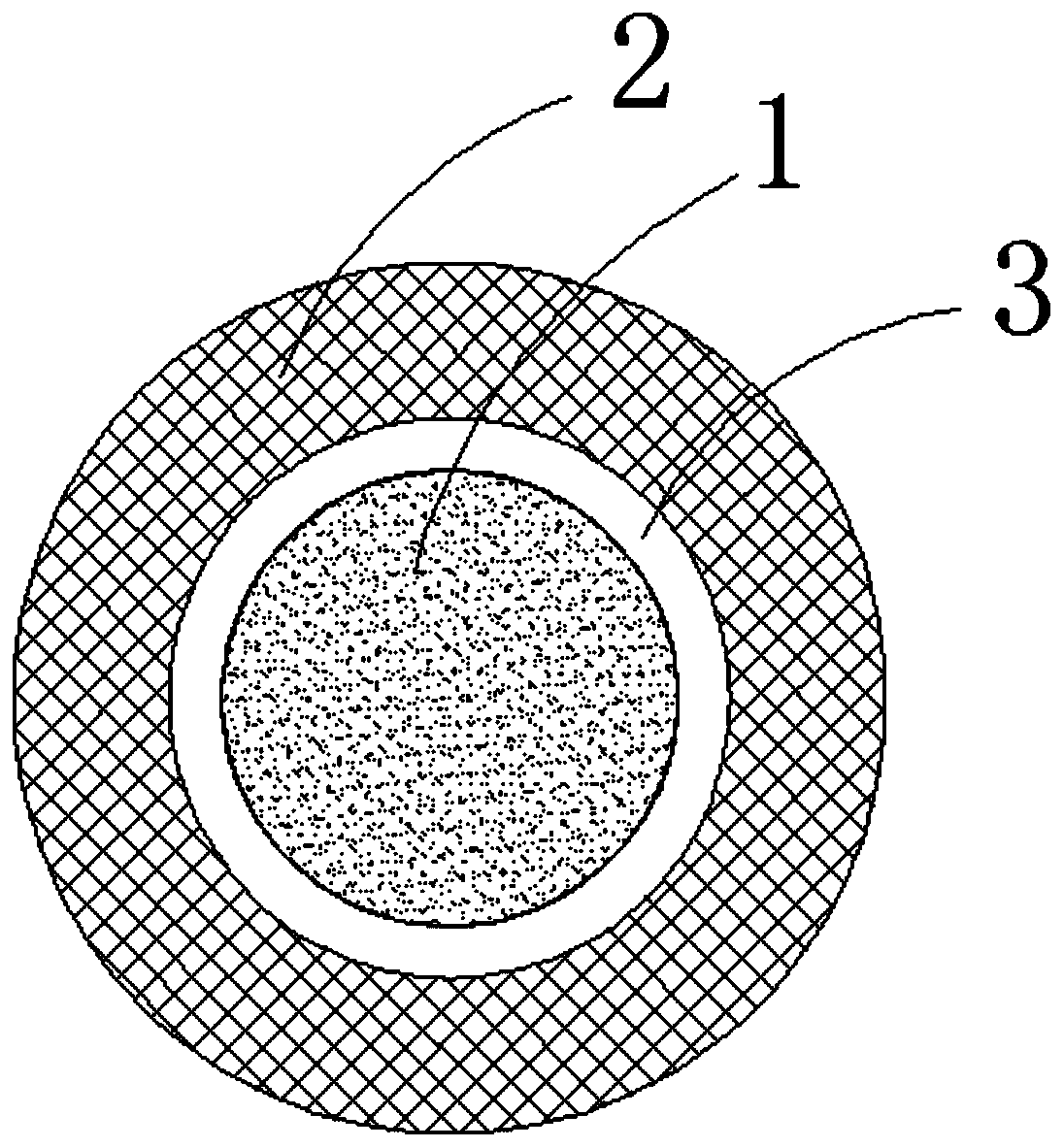

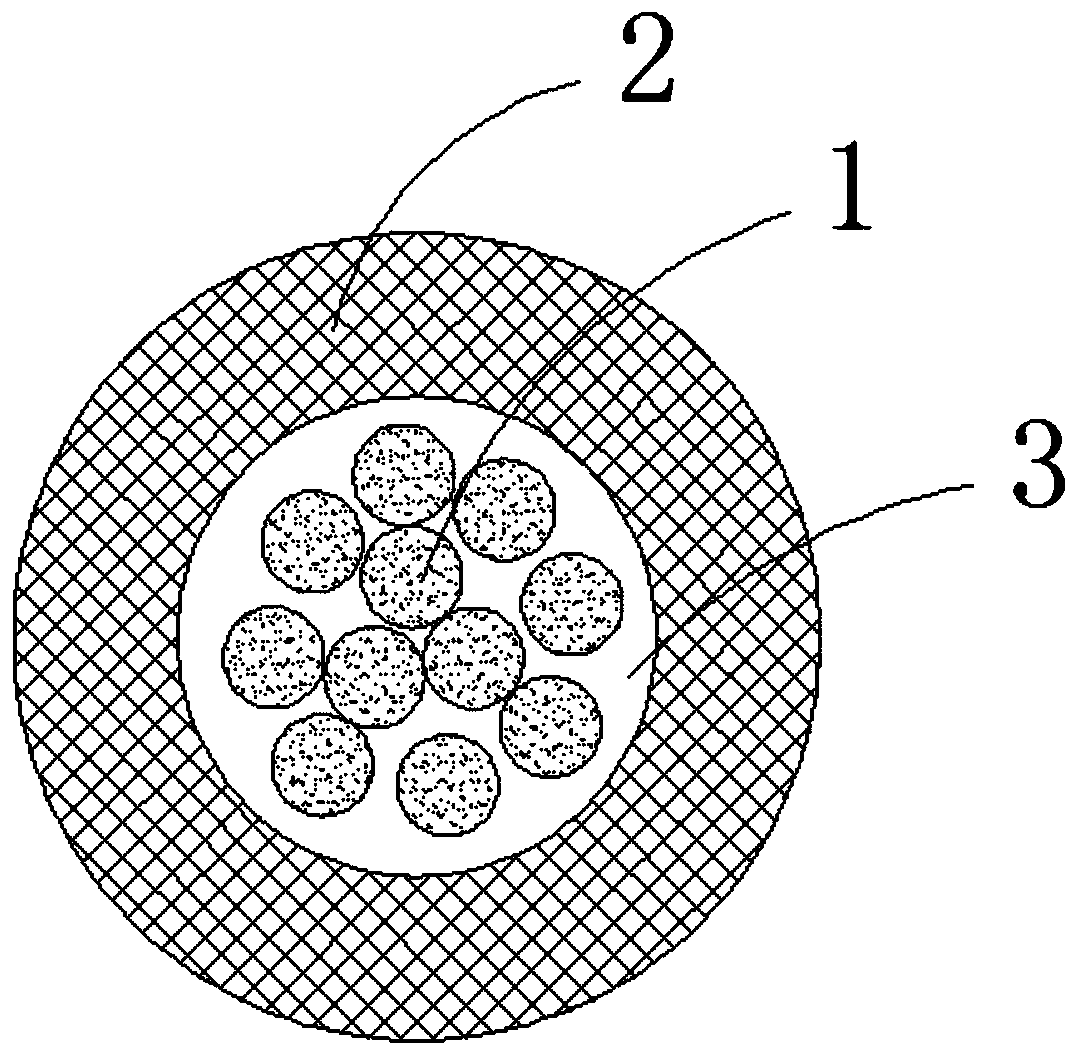

[0045] A PLA composite fiber filament, the PLA composite fiber filament has a skin-core structure, including an inner core layer 1 and an outer skin layer 2 wrapped outside it, and the inner core layer 1 is a continuous filament, the making of the filament The material is a degradable material, and the composition of the outer skin layer 2 includes PLA, which accounts for 80.0%-99.9% of the weight of the outer skin layer 2, and PLA refers to polylactic acid.

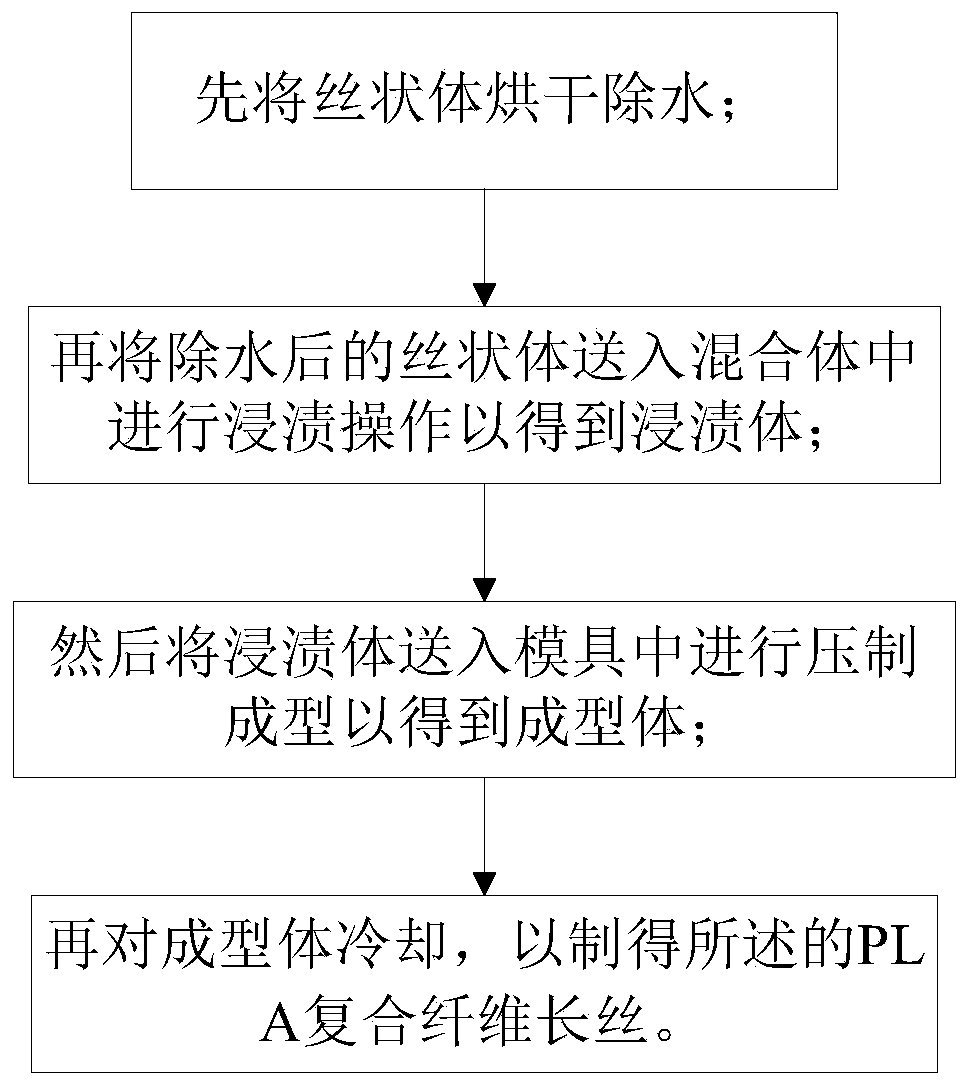

[0046] A manufacturing process of the above-mentioned PLA composite fiber filament, the manufacturing process includes the following steps: first drying the filamentous body to remove water, and then sending the dewatered filamentous body into a mixture for dipping operation to obtain an impregnated body, The mixture is a uniform mixture of plasticizer, anti-hydrolysis agent and molten PLA, and then the impregnated body is sent into a mold for compression molding to obtain a molded body, and then the molded body is cooled...

Embodiment 2

[0049] Basic content is the same as embodiment 1, the difference is:

[0050] The diameter of the filament is 0.05-0.5mm, and the thickness of the outer skin layer 2 is 0.05-0.3mm. Preferably, the ratio of the thickness of the outer skin layer 2 to the diameter of the filament is 0.2:1-1.2:1.

Embodiment 3

[0052] Basic content is the same as embodiment 1, the difference is:

[0053] A filament is a single fiber filament or a fiber bundle formed by a plurality of fiber filaments; the types of fiber filaments in the fiber bundle are the same or different. Preferably, the fiber filament is any one of viscose fiber, cotton fiber, hemp fiber, chitin fiber, alginic acid fiber, chitosan fiber, polyvinyl alcohol fiber, polycaprolactone fiber, and polyglycolic acid ester fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com