Bidirectional double-punching can body drawing machine

A technology for stretching machines and tanks, which is applied to stamping machines, presses, and other household appliances, etc. It can solve the problems of high design requirements for dynamic and static pressure bearings, large impact loads, and short service life, so as to reduce the use and maintenance costs , prolong service life and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: A two-way double-flushing can body stretching machine

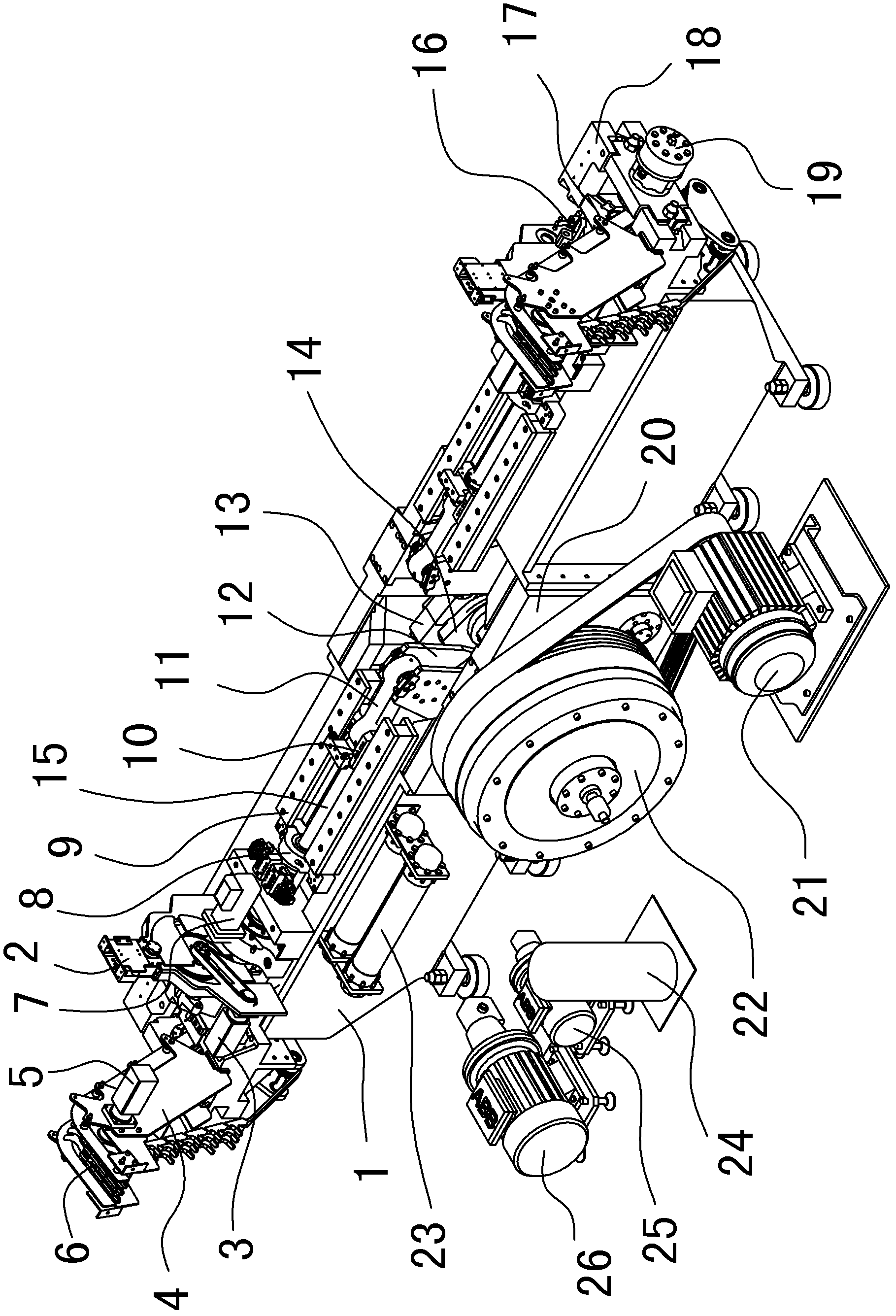

[0055] Such as Figure 4 As shown, the can stretching machine is composed of a box body 1, two sets of molds 16, two sets of crimping mechanisms 7, two sets of cup-inlet mechanisms 2, two sets of can-exit mechanisms 4 and a punch driving mechanism.

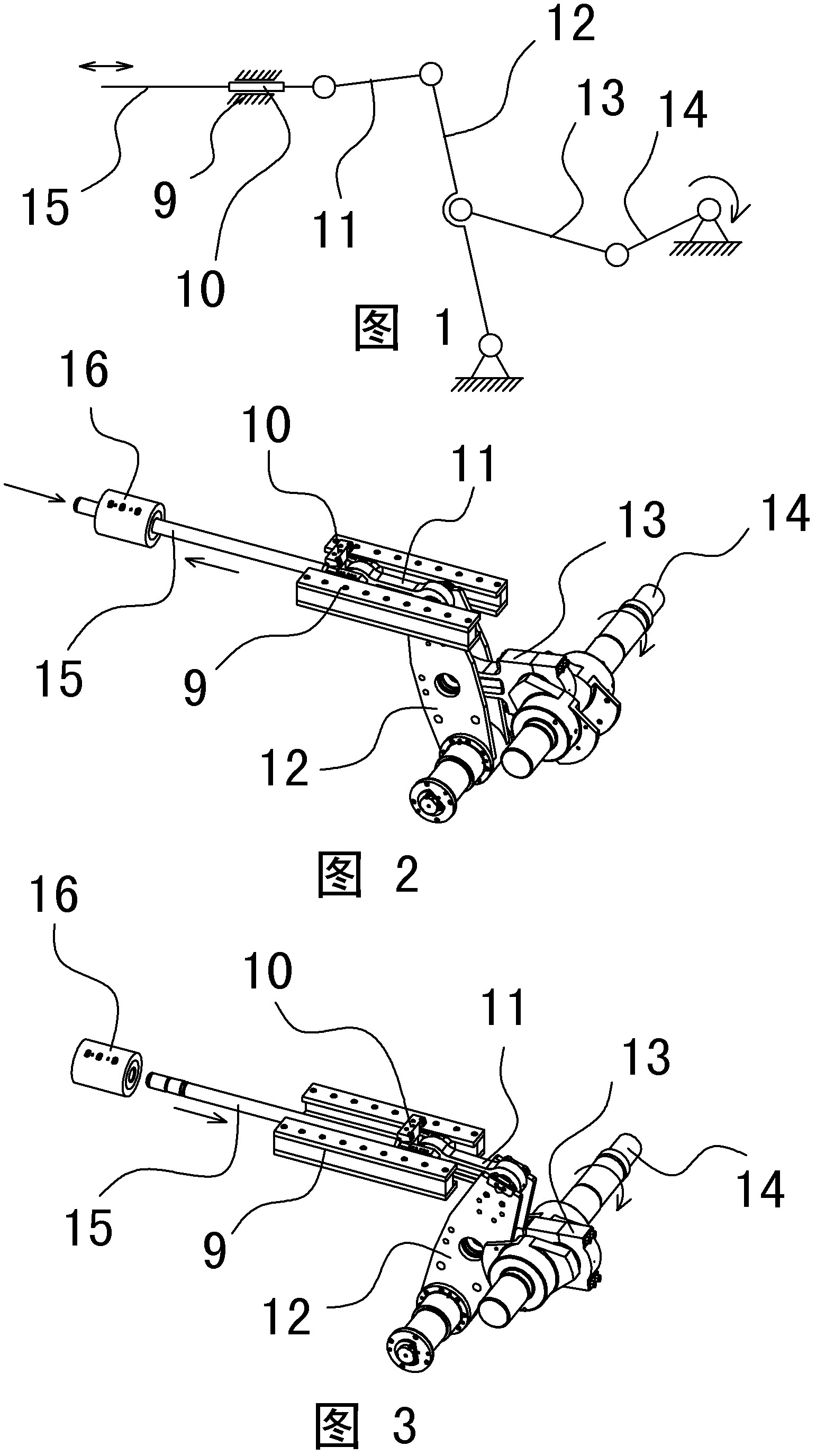

[0056] Such as Figure 5 and Figure 8 As shown, the punch driving mechanism consists of the following structures:

[0057] A crankshaft 14, the crankshaft 14 is rotatably supported by a bearing, and the supporting bearing adopts a dynamic and static pressure bearing. The crankshaft 14 is provided with a first crank throw and a second crank throw (see Figure 6 and Figure 7 ), the turning directions of the first crank throw and the second crank throw in the radial direction of the crankshaft 14 are opposite;

[0058] Two identical main links 13, i.e. a first main link and a second main link;

[0059] Two identical swing rods 12, i.e. a first swing ro...

Embodiment 2

[0073] Example 2: A two-way double-flushing can body stretching machine

[0074] refer to Figure 4 , the tank body stretching machine is composed of a box body 1, two sets of molds 16, two sets of edge-holding mechanisms 7, two sets of cup-inlet mechanisms 2, two sets of tank-exit mechanisms 4 and a punch driving mechanism.

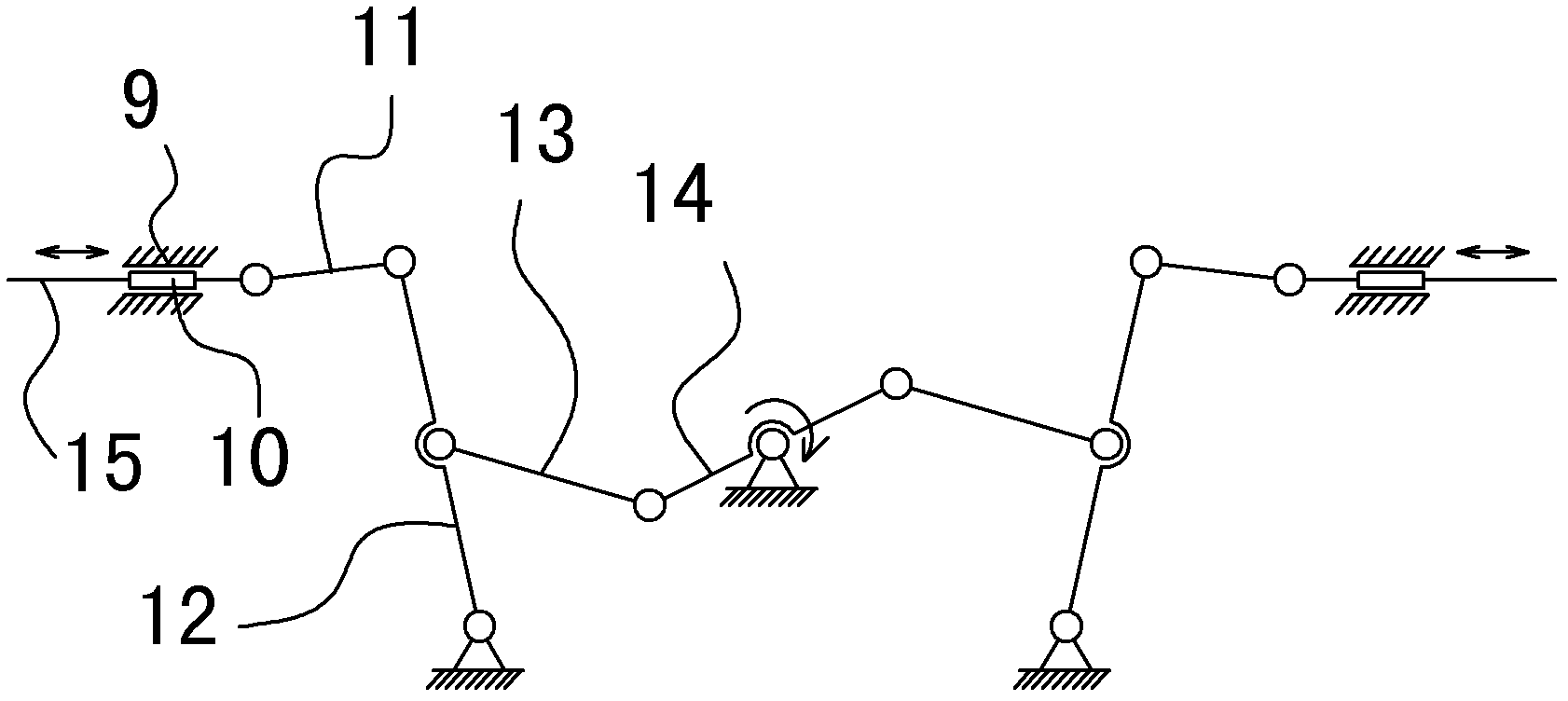

[0075] The difference from Embodiment 1 is that the crankshaft 14 in the punch driving mechanism consists of three crank throws, and there are three main connecting rods 13 .

[0076] Such as Figure 5 and Figure 12 As shown, the punch driving mechanism consists of the following structures:

[0077] A crankshaft 14, the crankshaft 14 is rotatably supported by bearings, the crankshaft 14 is provided with a first crankshaft, a second crankshaft and a 3rd crankshaft (see Figure 10 and Figure 11 ), the first crank throw, the second crank throw and the third crank throw are arranged sequentially in the axial direction of the crankshaft 14, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com