Novel energy-saving radial sliding bearing

A sliding bearing, a new type of technology, applied in the direction of sliding contact bearings, bearing components, shafts and bearings, can solve the problems of bearing capacity reduction, lubricating film pressure and bearing capacity reduction, etc., to achieve load capacity improvement, friction reduction and Improved energy-saving performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

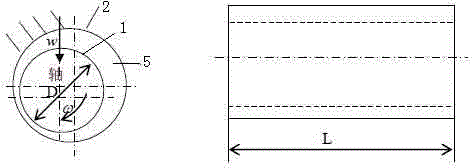

[0043] Embodiment A thin layer of material is coated on the bearing bush or the hole wall of the bearing seat 2 in the entrance area of the convergent wedge-shaped pores of the bearing, and the interface between the lubricating oil and the coating material has low adsorption strength and shear strength. When the bearing seat is stationary and the shaft 1 rotates during operation, the lubricating oil slips on the surface of this part of the coating material. Slip occurs.

[0044] According to the radial load direction of the bearing under the working conditions, the surface-treated bearing bush or bearing seat 2 hole wall is matched with the shaft 1 through installation, and there is a small gap formed between the bearing bush or the bearing seat 2 hole wall and the shaft 1. filled with lubricating oil. In this way, the rotational movement of the shaft 1 in a certain direction during work can form a lubricating oil film in the pores of the bearing hole 5, thus forming the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com