Dynamic monitoring system for operating condition of thrust bearing of hydro-generator

A technology for hydroelectric generators and thrust bearings, applied in mechanical bearing testing, etc., can solve problems such as temperature monitoring lag, bearing damage, and failure to give warnings in advance, and achieve the effect of small size and good anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

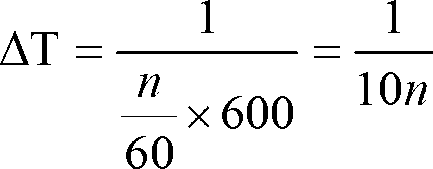

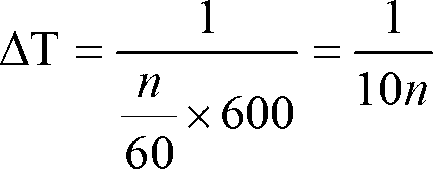

[0017] Such as figure 1 The dynamic monitoring system for the running state of the thrust bearing of the hydro-generator shown includes a temperature sensor, a pressure sensor, an oil film thickness sensor, a host computer, and a remote computer. The host computer includes PCM-3363CPU module U1, PCM-3910 power supply module U2, and PCM-3835 memory Module U3, PCM-3718H multi-function acquisition module U4, signal conditioning module U5, wi-fi wireless routing module U6, among which U1, U2, U3, and U4 modules use PC104 bus, and there are pins and jacks for bus connection on the modules , U1, U2, U3, and U4 are sequentially connected together through these pins and jacks to form a stack structure. U5 is connected to the signal interface on U4 through a signal connection line, and U6 is connected to the network port of U1 through a network cable. The output signals of oil film thickness sensors S11, S12, S13, S14, pressure sensors S21, S22, S23, S24 enter the data acquisition car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com