Water lubrication bearing dynamic characteristic parameter test device

A technology of water-lubricated bearings and dynamic characteristics, applied in the direction of mechanical bearing testing, etc., can solve problems such as stiffness and damping test devices are rare, affect shafting propulsion efficiency, operation reliability and operation safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

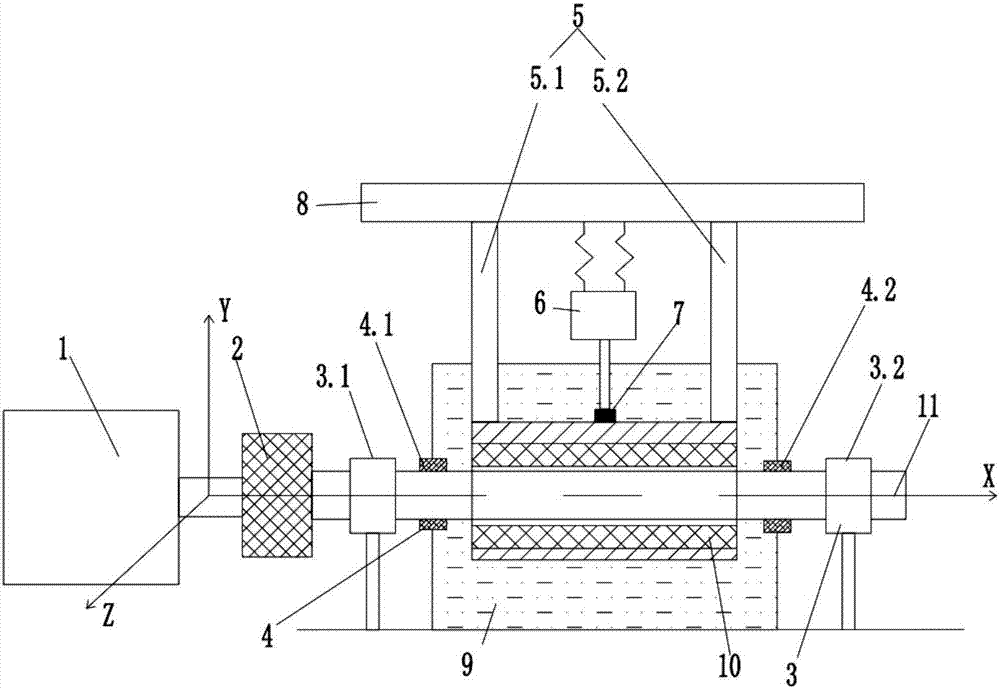

[0021] Before the test, the test device needs to be installed in place first, the specific installation method is as follows: figure 1 As shown, the connecting shaft section 11 is penetrated from one end of the water tank 9, and at the same time, the water lubricated bearing 10 is hoisted to ensure that it is concentric with the connecting shaft section 11, so that the water lubricated bearing 10 to be tested is set on the corresponding connecting shaft section 11. position, then pass the coupling shaft section 11 from the other end of the water tank, and install the two ends of the coupling shaft section 11 on the roller bearings and supports 3 (3.1, 3.2) on the outside of the water tank 9; The static force loading device 5 on the top controls and adjusts its position and attitude; a dynamic sealing device 4 (including dynamic sealing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com