Homogeneous-phase multi-element porous oxide material, preparation method and application thereof

A porous oxide, multi-component technology, applied in the preparation of oxide/hydroxide, chemical instruments and methods, vanadium oxide, etc., can solve the problems of no advantage in utilization, low material density, etc. The effect of the advantages of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

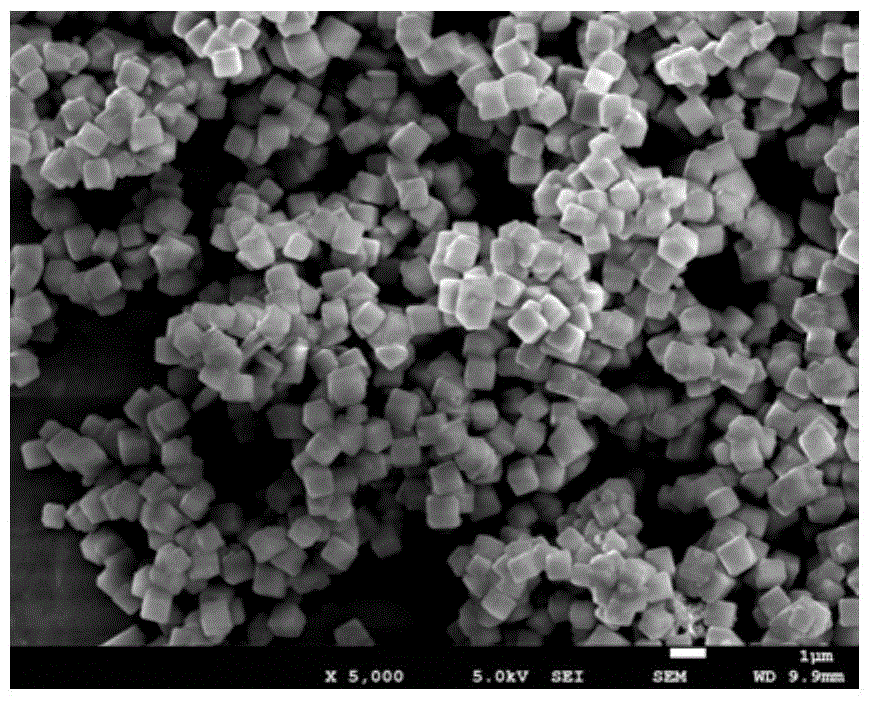

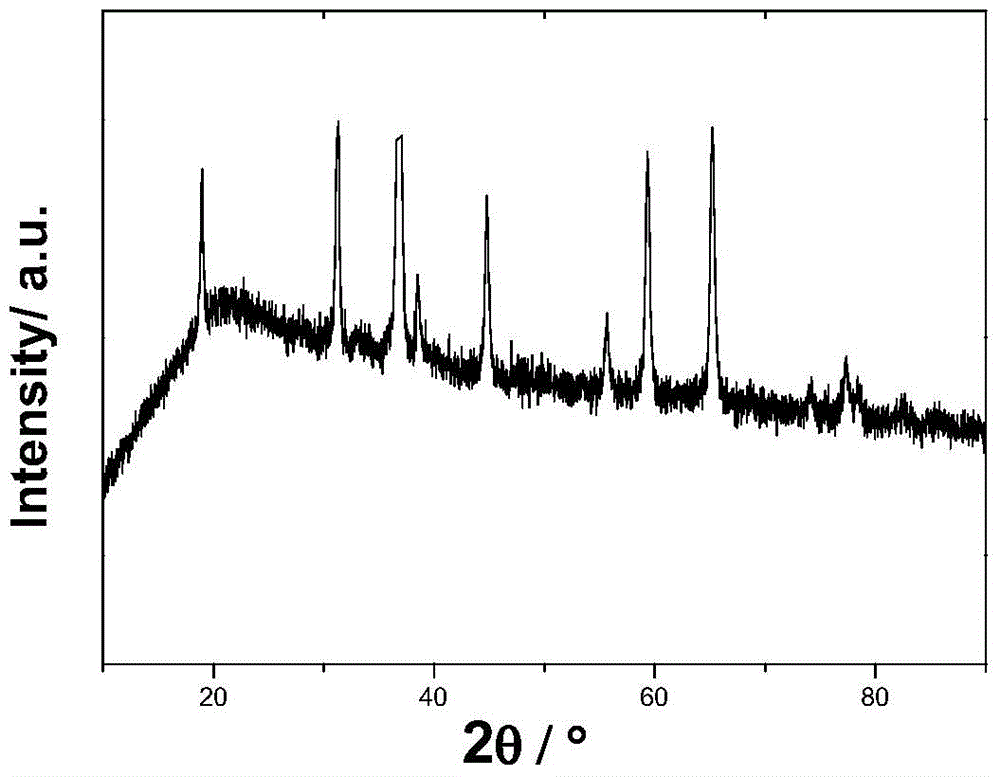

Embodiment 1

[0032] Accurately weigh 0.16 mg of 2-methylimidazole, add it into 100 mL of deionized water, stir until completely dissolved, then add 3 mL of concentrated ammonia water, continue stirring for 10 min, and set aside. Add 0.19883 mg of ferrous chloride to 100 mL of deionized water, stir until completely dissolved, then add the prepared mixed solution of 2-methylimidazole and concentrated ammonia water, stir and react at room temperature for 10 minutes, and obtain nickel-zinc binary Metal-organic framework compound, the compound was suction-filtered, washed three times with deionized water, dried at 80°C for 12h, then heated from room temperature to 450°C at a rate of 2°C / min, and kept at this temperature for 1h, then naturally The temperature is lowered to obtain a multi-component porous oxide material.

Embodiment 2

[0034]Accurately weigh 0.83 mg of terephthalic acid, add it to 100 mL of deionized water, stir until completely dissolved, then add 9 mL of concentrated ammonia water, continue stirring for 20 min, and set aside. Add 0.8 mg of manganese sulfate and 0.786505 mg of vanadium chloride into 100 mL of deionized water, stir until completely dissolved, then add the prepared mixed solution of terephthalic acid and concentrated ammonia water, and stir for 1 min at room temperature to obtain nickel- Zinc binary metal-organic framework compound, the compound is suction-filtered, washed with deionized water five times, dried at 60°C for 2 hours, then heated from room temperature to 200°C at a rate of 0.1°C / min, and kept at this temperature 2h, and then naturally lower the temperature to obtain a multi-component porous oxide material.

Embodiment 3

[0036] Accurately weigh 7.33mg of tetra-pyridinecarboxylic acid (HIN), add it into 100mL of deionized water, stir until completely dissolved, then add 9mL of concentrated ammonia water, continue stirring for 30min, and set aside. Add 3.3mg of zinc acetate and 5.07mg of nickel nitrate into 100mL of deionized water, stir until completely dissolved, then add the prepared mixed solution of tetrakis-pyridinecarboxylic acid (HIN) and concentrated ammonia water, and stir at room temperature for 3 minutes to obtain Nickel-zinc binary metal-organic framework compound, the compound was suction-filtered, washed five times with deionized water, dried at 50°C for 4 hours, and then heated from room temperature to 300°C at a rate of 0.3°C / min, and at this temperature The temperature was kept at a constant temperature for 3 hours, and then the temperature was naturally lowered to obtain a multi-component porous oxide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com