Longan pitting machine

A longan and frame technology, which is applied in the fields of fruit pitting device, food science, application, etc., can solve the problems that the longan positioning device has no flexibility, is not suitable for shelling longan fruit, and a large amount of longan minced meat, etc., and achieves high cost performance, The effect of simple structure and small hole size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

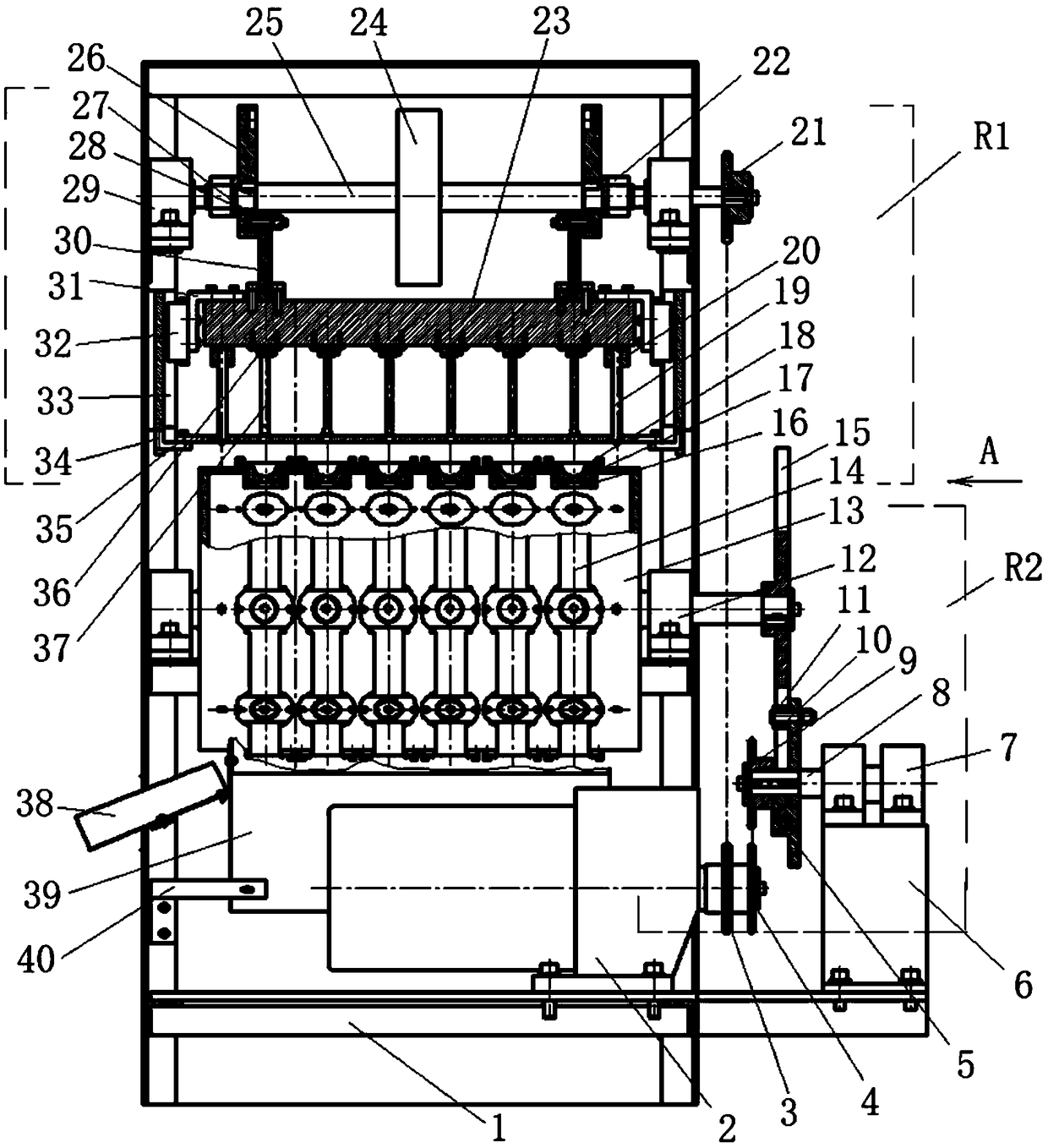

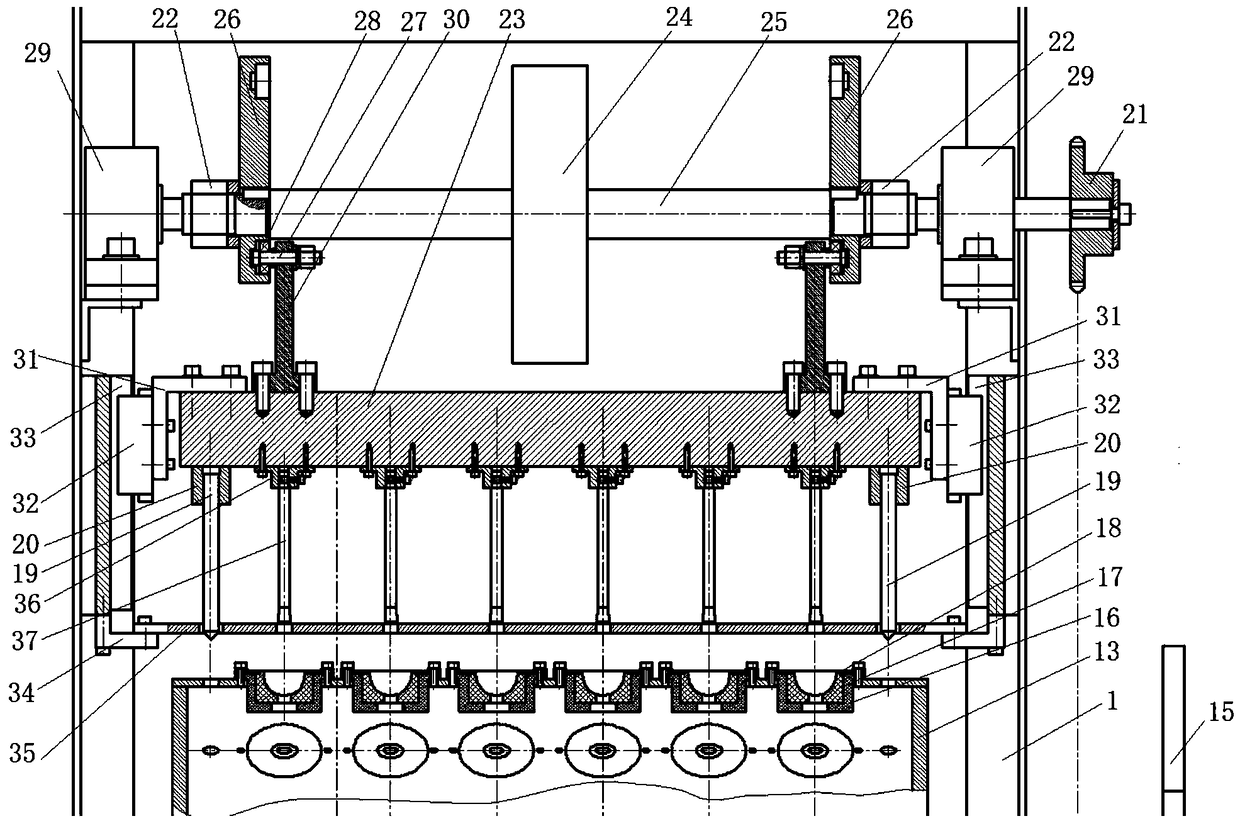

[0026] Such as Figure 1-Figure 7 Shown, a kind of longan pitting machine is made up of frame 1, pitting assembly I, and cutting assembly II. The core removal assembly I is located at the front of the frame 1; the unloading assembly II is located at the rear upper portion of the frame 1.

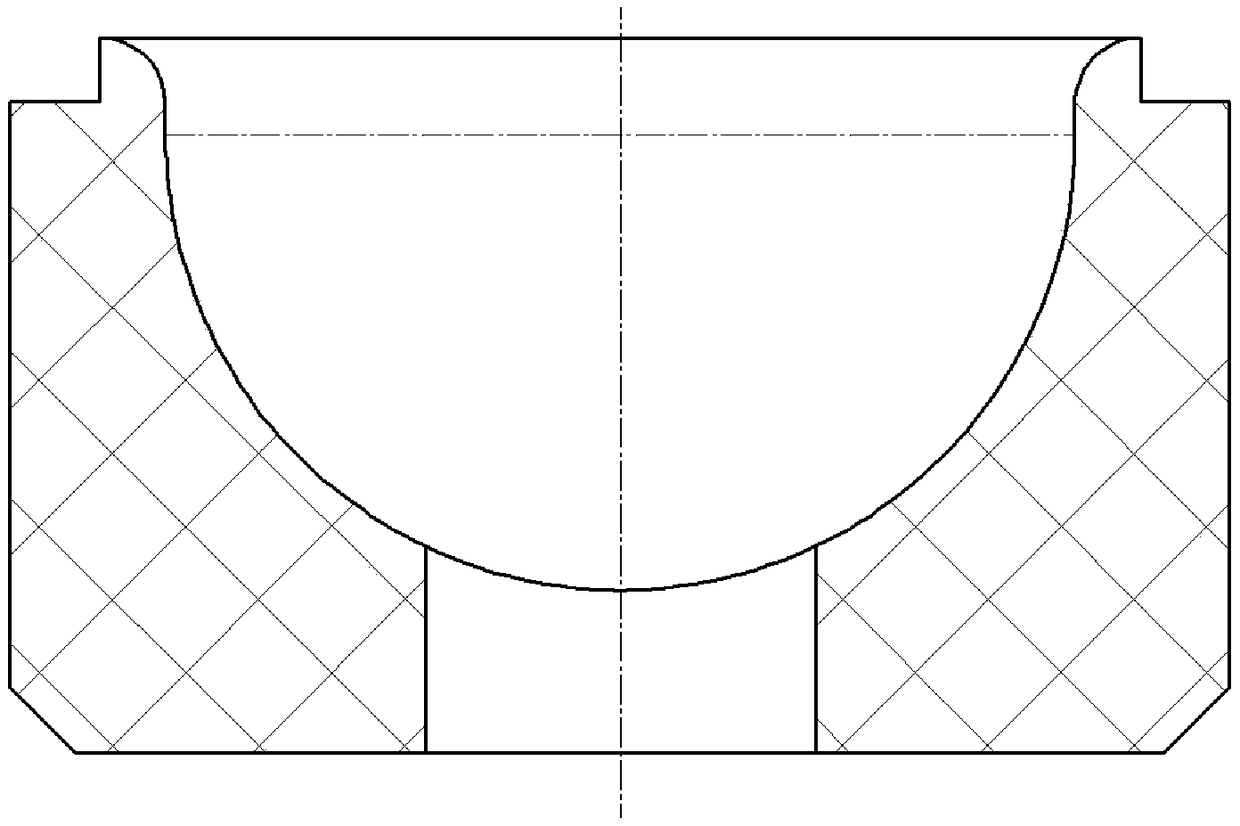

[0027] Go nuclear assembly 1 by main motor 2, the first sprocket wheel 3 of main motor, the second sprocket wheel 4 of main motor, runner 5, runner fixed mount 6, runner belt seat bearing 7, runner fixed shaft 8, runner Transmission sprocket 9, runner pin 10, repin bearing 11, roller seat bearing 12, roller 13, arc-shaped fruit guide block 14, sheave 15, top core rubber fixing sleeve 16, top core rubber 17, top core rubber Compression ring 18, guide post 19, guide post fixing seat 20, upper shaft transmission sprocket 21, eccentric wheel fixing nut 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com