A hot rod saw

A technology of hot rods and cutting saws, which is applied in the direction of sawing machine devices, metal sawing equipment, metal processing equipment, etc., which can solve the problems of horizontal cutting aluminum rod costs, unrivaled sawing rods, and not easy to discharge, so as to save materials , High material utilization rate, the effect of saving raw material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, invention is described in further detail.

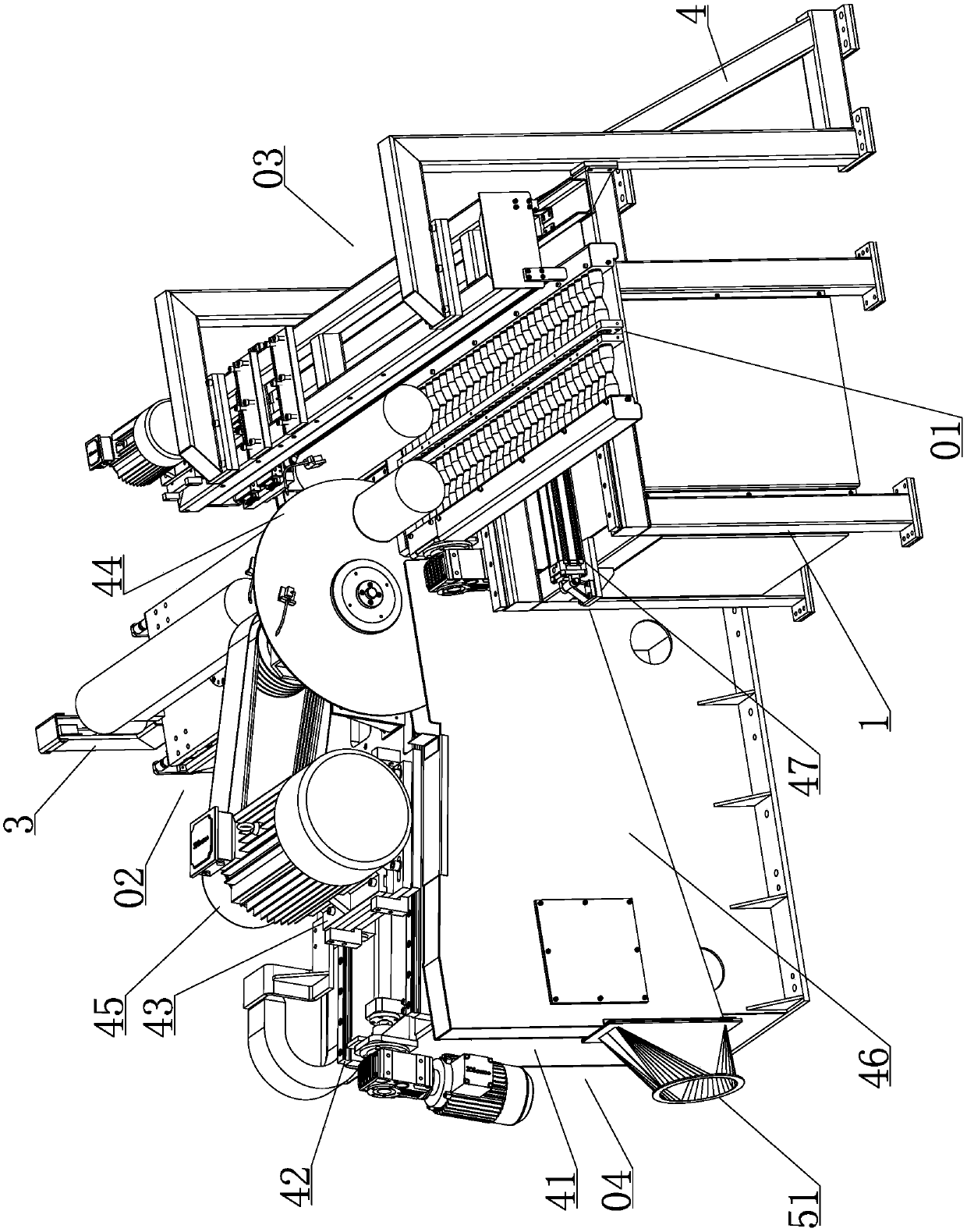

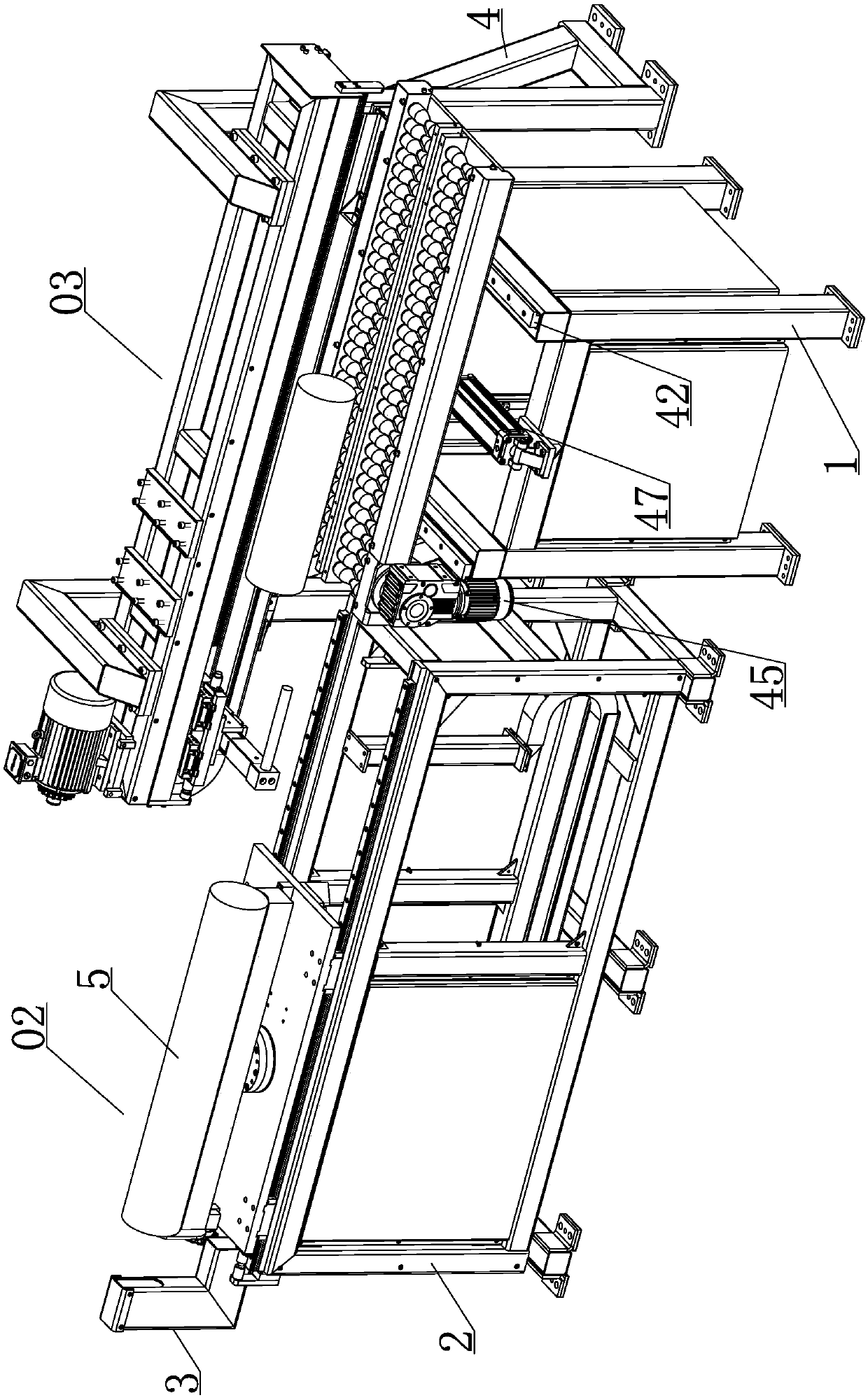

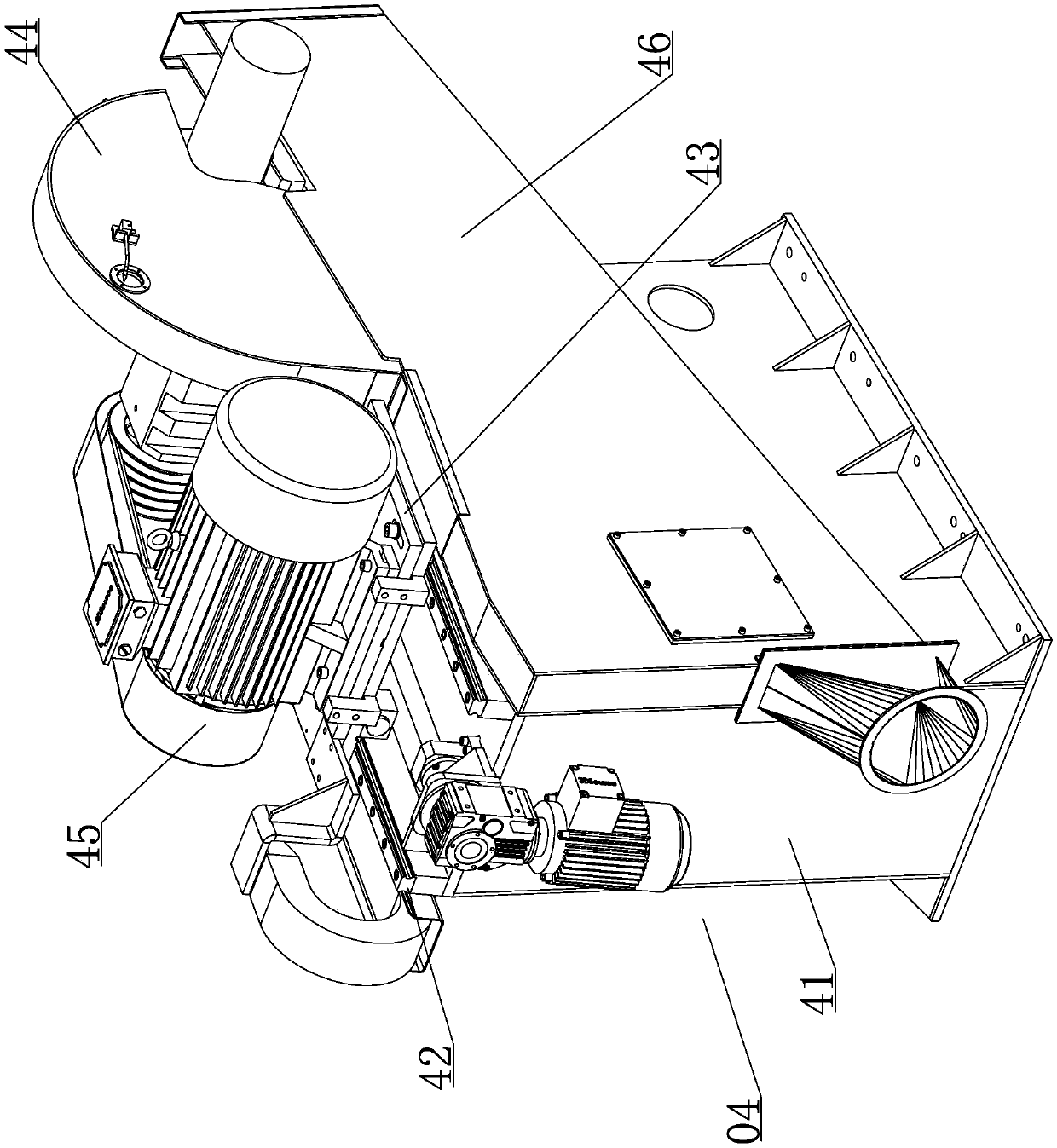

[0023] Such as Figure 1-7 and Figure 9 Shown, a kind of hot bar saw comprises a first support 1, a feed table 01 for conveying aluminum rods 5 is provided on the first support 1, a second support 2 is provided on one side of the first support 1, and a second support 2 is provided on the second support. The support 2 is provided with a rotating table 02 for rotating the aluminum rod 5, a laser measuring instrument 3 for measuring the length of the aluminum rod 5 is provided on the end of the second support 2, and a third support 4 is provided on one side of the first support 1. 1. On the third support 4, there is a transportation aid device 03 that cooperates with the feeding table 01 to transport the aluminum rod 5, and a sawing device 04 is provided between the first support 1 and the second support 2. The sawing device 04 comprises a support 41, on which the support 41 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com