Graded porous polyvinylidene fluoride hollow-fiber composite film and production method thereof

A polyvinylidene fluoride, graded porous technology, applied in the field of water treatment, can solve the problems of high cost, large pore size, cumbersome process, etc., and achieve the effects of simple and controllable production process, low manufacturing cost and fast transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

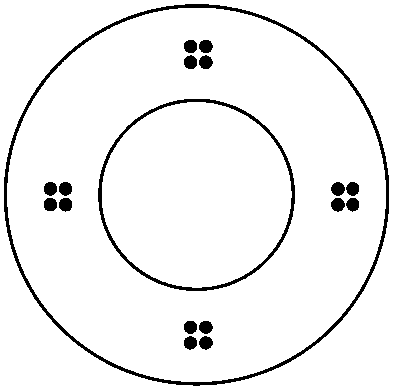

[0033] A hierarchically porous polyvinylidene fluoride hollow fiber composite membrane, as attached figure 1 And attached Figure 6 As shown in the cross-sectional schematic diagram and the cross-sectional electron microscope image, it includes a hierarchically porous macroporous intermediate layer and an outer separation layer and an inner separation layer covering both sides of the macroporous intermediate layer. The three-layer structure is integrally formed of the same material, and the adjacent two layers of pores are connected. , the outer separation layer and the inner separation layer are denser than the macroporous middle layer, the thickness of the spongy body in the outer separation layer is 100 µm, and the thickness of the spongy body in the inner separation layer is 20 µm. The sponge body of the outer separation layer and the sponge body of the inner separation layer have an asymmetric structure, and their pores are honeycomb or columnar. Increased and highly conne...

Embodiment 2

[0042] Other parts are the same as in Example 1, except that the outer diameter of the hollow fiber composite membrane is about 1400 μm, and the wall thickness is about 300 μm, as shown in the attached Figure 8 The cross-section shown at 200 times magnification shows that the middle layer of the membrane is micron-scale macropores, while the inner and outer end surfaces are a hierarchical porous structure of a slightly dense sponge body, which was tested under a pressure of 0.1 MPa at a total length of 100 cm. The pure water flux at 25°C is 730 L / (m2h), the porosity of the membrane filament is 85 Vol.%, and the bubble point pressure of the membrane is 0.55 MPa in the standard wetting liquid Porefil test of 16 dyn / cm. Pressure ≥ 0.8 MPa. The water contact angle of the wet film after drying is 65°, the tensile breaking strength of the film is 19 MPa, and the crystallinity is 48%.

[0043] Polyvinylidene fluoride resin (Sanaifu 904), organic polar solvent N-methylpyrrolidone (N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com