Composite membrane as well as preparation method and the application thereof in gas separation and purification

A composite membrane and polymer membrane technology, applied in the field of composite membranes, can solve the problems of high gas permeability and high gas selectivity, low gas permeability, high equipment requirements, etc., so as to improve separation and purification performance and high gas selection. The effect of sex, good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

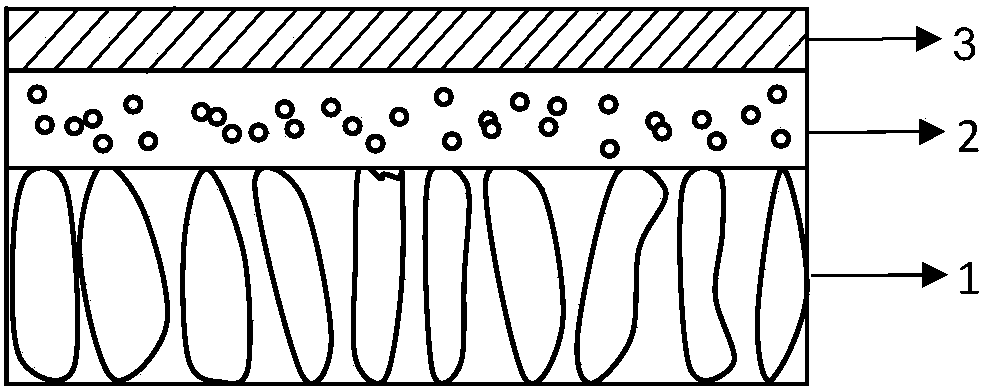

[0034] In this example, the composite membrane structure is as figure 1 As shown, the porous α-Al 2 o 3 The hollow ceramic fiber tube is a support body 1 with an outer diameter of 3.5 mm, an inner diameter of 2.5 mm, and an average pore diameter of 100 nm; the surface of the support body is a double-layer membrane, that is, the surface of the support body is a transition layer 2, and the transition layer is composed of 5:1 1,2-bis(triethoxysilyl)ethane (BTESE) and hydrochloric acid precursor solution generated at room temperature is diluted, sintered, and dried organic-inorganic porous material, the surface of the transition layer It is a polyimide film 3 .

[0035] The preparation method of this composite film is as follows:

[0036] (1) Preparation of precursor sol and dilute polyimide solution

[0037] Mix 0.0206g of concentrated hydrochloric acid, 3g of deionized water and 1.0197g of absolute ethanol to obtain a hydrochloric acid mixture; add the hydrochloric acid mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com