Improving method for pipeline burying construction of infilled wall

A technology for buried construction and wall filling, which is applied in the treatment of walls, building materials, and building components. High positioning accuracy, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

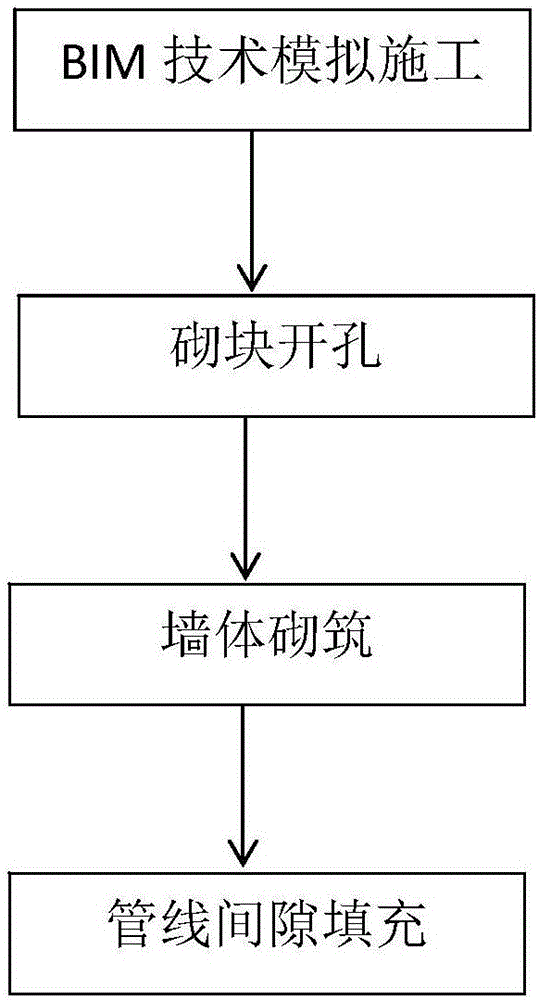

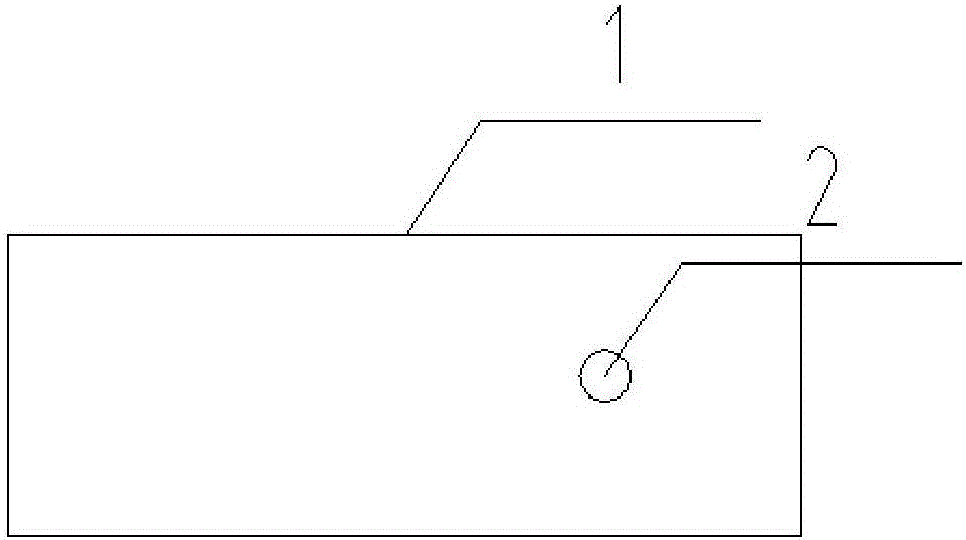

[0045] An improved method for concealed burying construction of a block wall pipeline. The block wall is as follows figure 2 The shown infill wall block 1 composition, the process of the improvement method for the construction of the buried pipeline of the block wall, such as figure 1 As shown, it consists of four processes: 1. BIM technology simulation construction; 2. block opening; 3. wall masonry; 4. pipeline gap filling. The operation techniques of the four procedures are as follows:

[0046] 1. BIM technology simulation construction

[0047] Use BIM technology to simulate construction according to the design drawings. Mark the infill wall block 1 with the serial number in order, and accurately locate the pipeline position on the infill wall block 1 with the serial number, and mark it on the corresponding block. Make preparations in one step;

[0048] Second, the block opening

[0049] Before the infill wall block 1 is built, according to the pipeline position marked on the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com