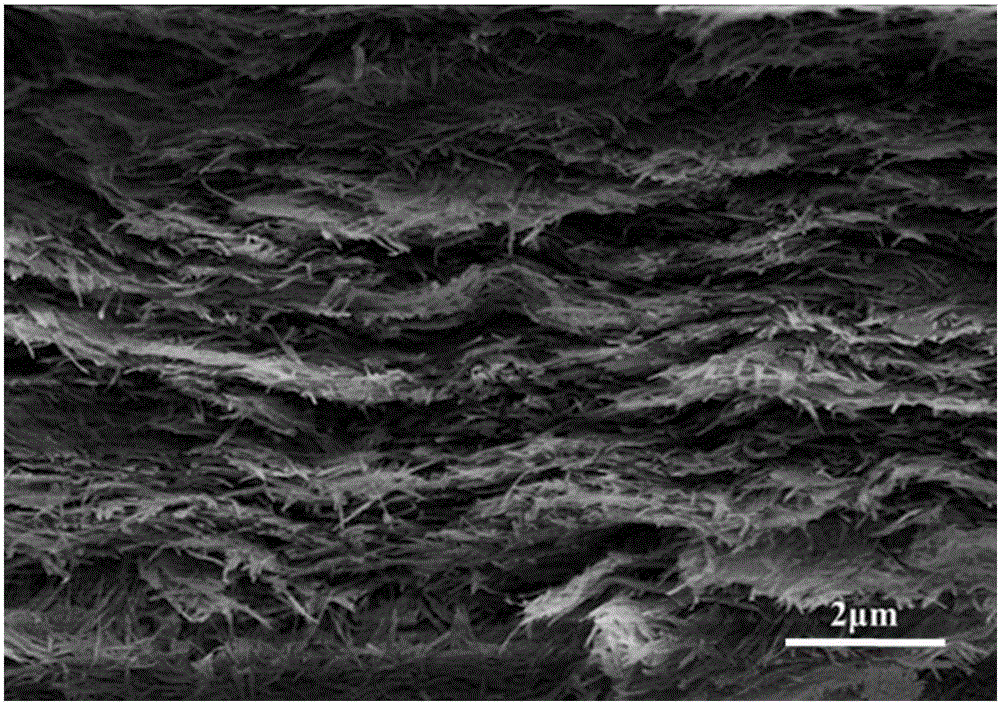

Self-supported attapulgite nanofiber membrane, and preparation method thereof

A technology of nanofiber membrane and attapulgite, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problem of rare attapulgite, achieve the effect of rich raw materials, high mechanical strength, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Disperse attapulgite in aqueous solution at room temperature, ultrasonically disperse, take the upper suspension, enrich to obtain attapulgite colloid, and prepare attapulgite colloid (solid content is 2wt%), and then 10mL of Add polyvinyl alcohol solution (1wt%) into 60 mL of attapulgite colloid at a rate of 0.5 mL / min, and stir for 24 h.

[0028] (2) Concentrate the mixed solution in step 1 in a rotary evaporator, specifically at 50°C for 3 hours and 80°C for 30 minutes to obtain a mixed slurry with a water content of 60%;

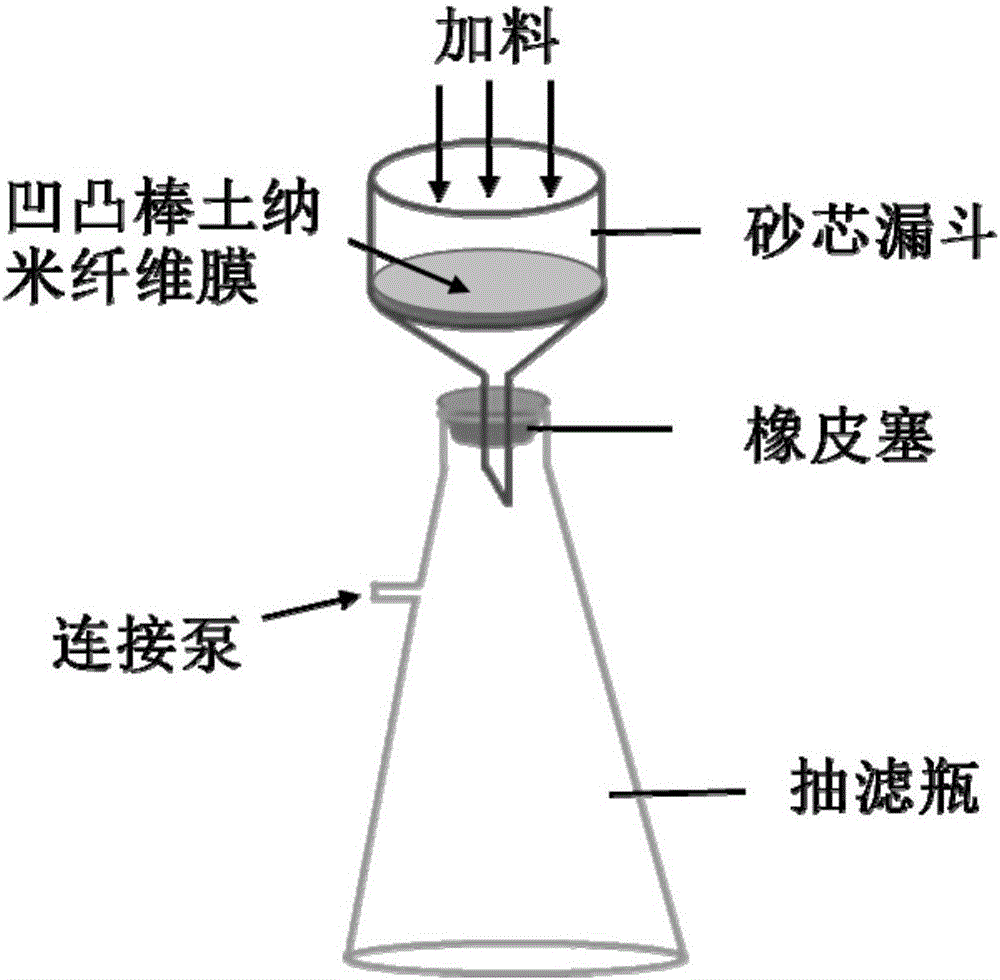

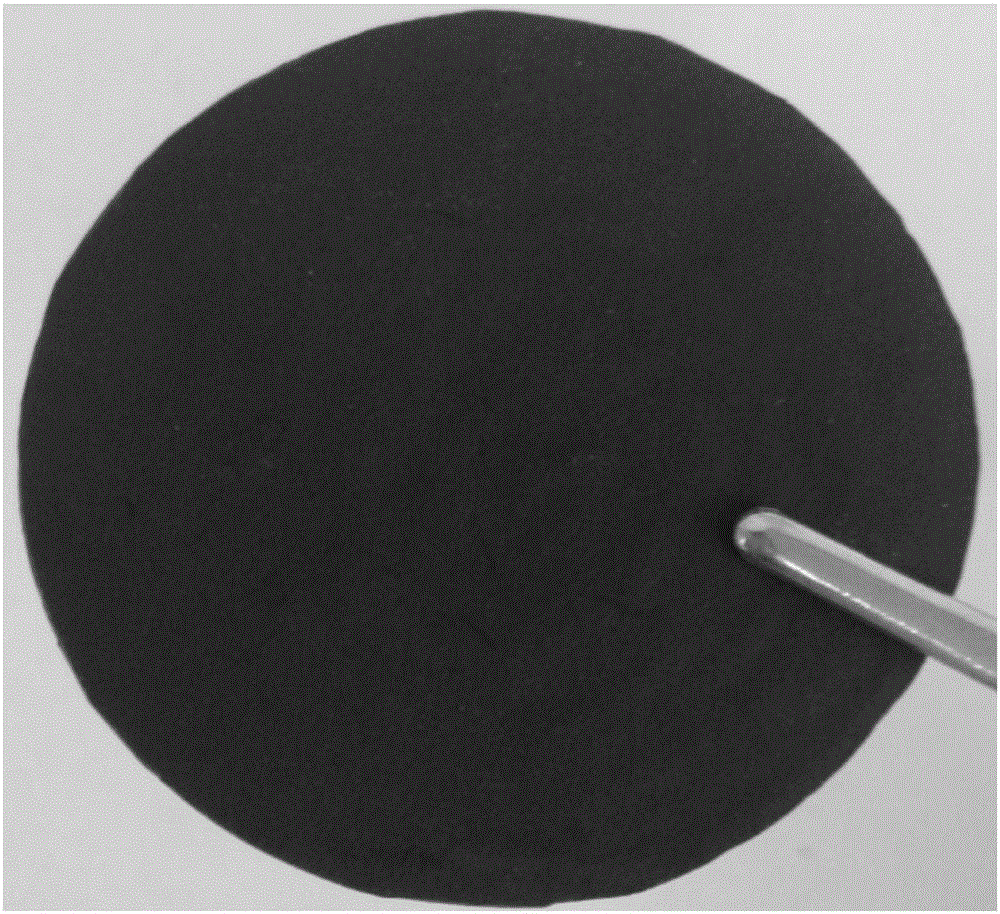

[0029] (3) Place the mixed slurry in step 2 in a self-made suction filtration device, and filter under a pressure of 0.1 MPa for 1 hour, and dry the prepared membrane material at 40°C for 24 hours to obtain an attapulgite nanofiber membrane .

[0030] (4) Place the attapulgite nanofiber membrane in step 3 in a vacuum tube furnace, sinter it in a nitrogen atmosphere, raise the temperature from room temperature to 240°C at a rate of 1K / min, kee...

Embodiment 2

[0034] (1) Disperse attapulgite in aqueous solution at room temperature, ultrasonically disperse, take the upper suspension, enrich to obtain attapulgite colloid, and prepare attapulgite colloid (solid content is 2wt%), and then 5mL of Add polyvinyl alcohol solution (1wt%) into 60 mL of attapulgite colloid at a rate of 0.2 mL / min, and stir for 24 h.

[0035] (2) Concentrate the mixed solution in step 1 in a rotary evaporator, specifically at 50°C for 3 hours and 80°C for 30 minutes to obtain a mixed slurry with a water content of 60%;

[0036] (3) Place the mixed slurry in step 2 in a self-made suction filtration device, and filter under a pressure of 0.1 MPa for 1 hour, and dry the prepared membrane material at 40°C for 24 hours to obtain an attapulgite nanofiber membrane .

[0037] (4) Place the attapulgite nanofiber membrane in step 3 in a vacuum tube furnace, sinter it in a nitrogen atmosphere, raise the temperature from room temperature to 240°C at a rate of 1K / min, keep...

Embodiment 3

[0041] (1) Disperse attapulgite in aqueous solution at room temperature, ultrasonically disperse, take the upper suspension, enrich to obtain attapulgite colloid, and prepare attapulgite colloid (solid content is 2wt%), and then 10mL of Add polyethylene glycol solution (1 wt%) into 60 mL of attapulgite colloid at a rate of 0.5 mL / min, and stir for 24 h.

[0042] (2) Concentrate the mixed solution in step 1 in a rotary evaporator, specifically at 50°C for 3 hours and 80°C for 30 minutes to obtain a mixed slurry with a water content of 60%;

[0043] (3) Place the mixed slurry in step 2 in a self-made suction filtration device, and filter under a pressure of 0.1 MPa for 1 hour, and dry the prepared membrane material at 40°C for 24 hours to obtain an attapulgite nanofiber membrane .

[0044] (4) Place the attapulgite nanofiber membrane in step 3 in a vacuum tube furnace, sinter it in a nitrogen atmosphere, raise the temperature from room temperature to 240°C at a rate of 1K / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com