Material conveying control method

A technology of conveying control and conveyor belt, which is applied in the field of material conveying control, and can solve problems such as product leakage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

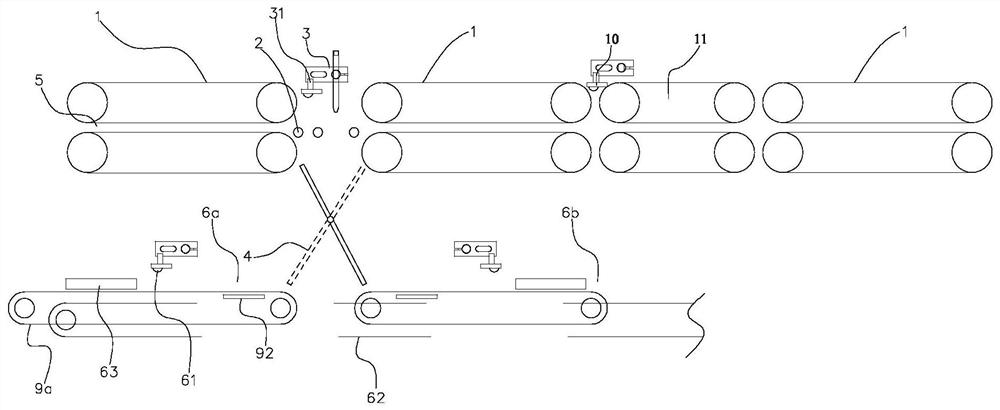

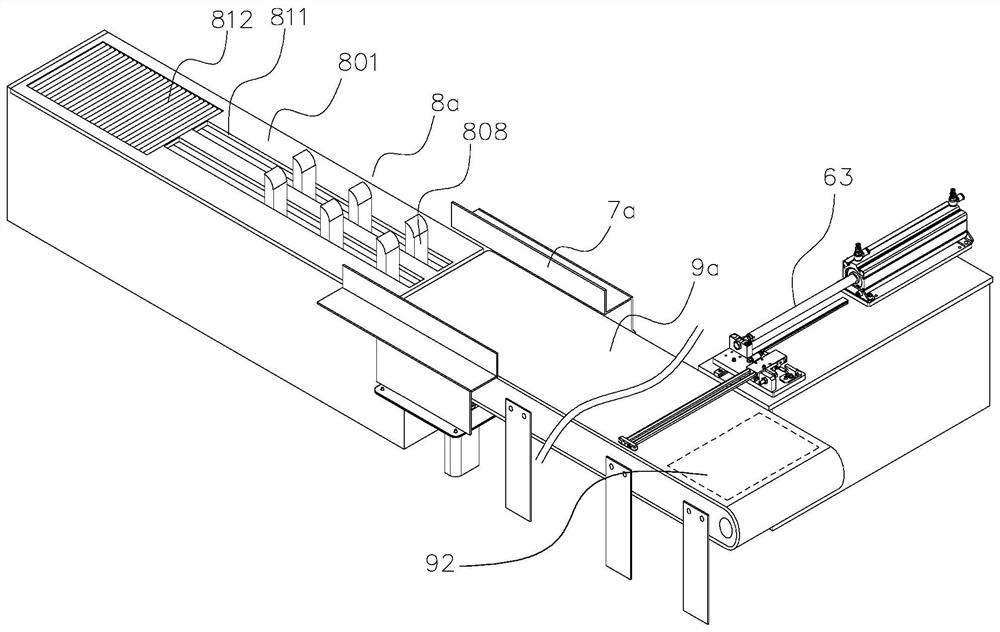

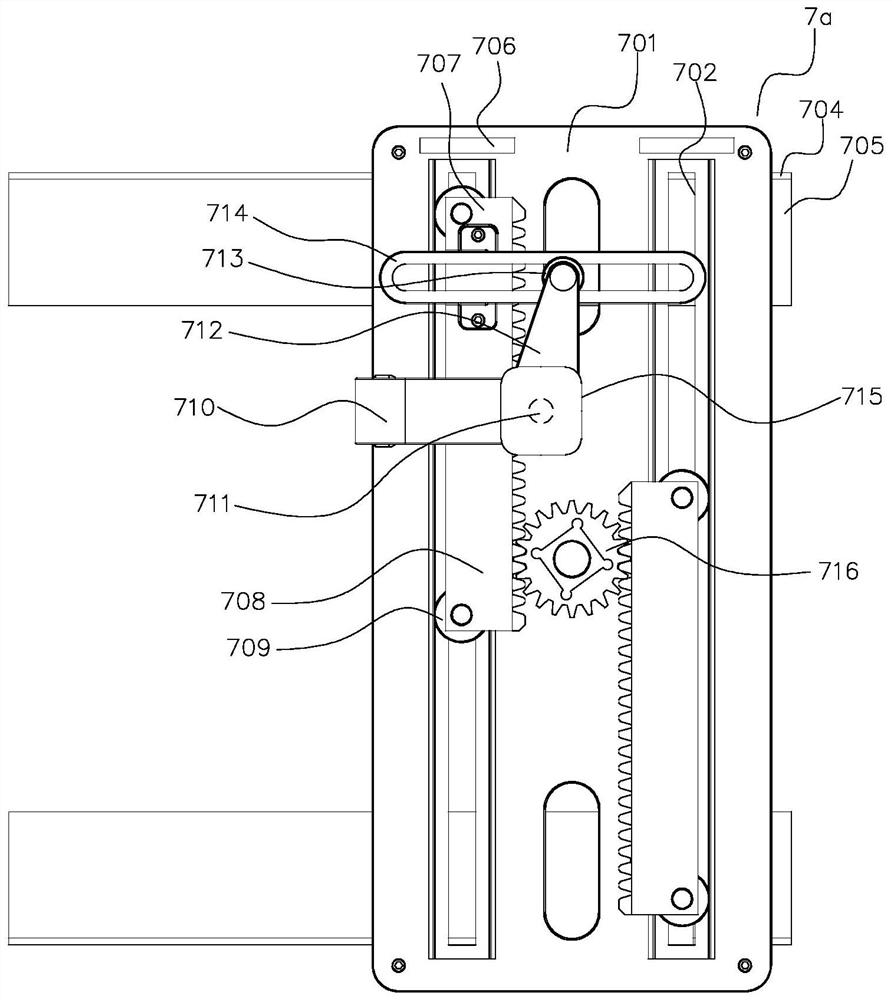

[0039] refer to Figures 1 to 14 , the present embodiment provides a material delivery control method, comprising the following steps:

[0040] Step 1: The sanitary products are transported through the clamping conveying device, and the high-speed camera scans and counts the passing sanitary products. When the waste products are detected, the rejecting device ejects high-pressure gas from the bottom to remove the passing waste products. The conveying device continues to input sanitary products. At the same time, the high-speed camera counts and marks the sanitary product conveyed after the rejection, and marks the sanitary product conveyed after the rejection as red, and the clamping conveying device inputs the sanitary product conveyed after the rejection to The speed-regulating conveyor belt, the detection camera component in front of the speed-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com