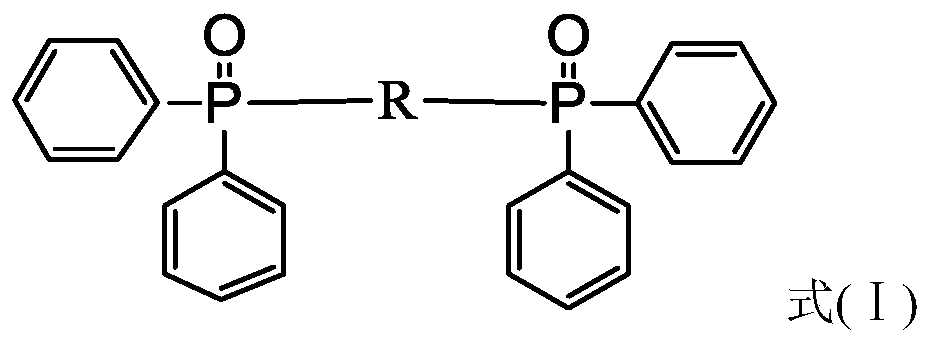

Halogen-free flame-retardant epoxy resin composition and application thereof

A technology of epoxy resin and composition, applied in the field of halogen-free flame retardant epoxy resin composition, can solve the problems of insufficient heat resistance, decreased mechanical properties, poor product dielectric properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

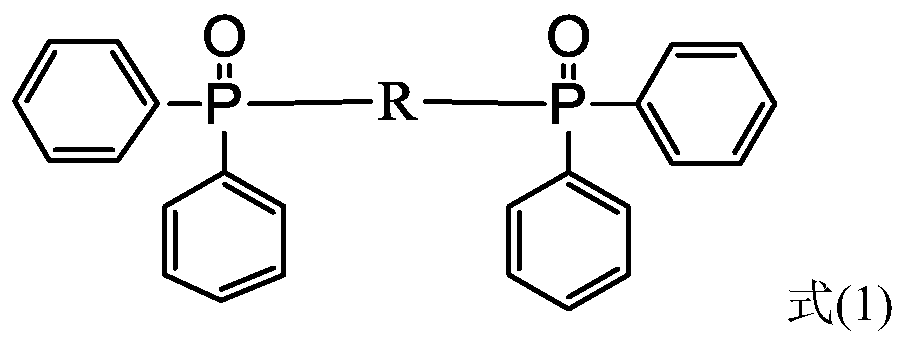

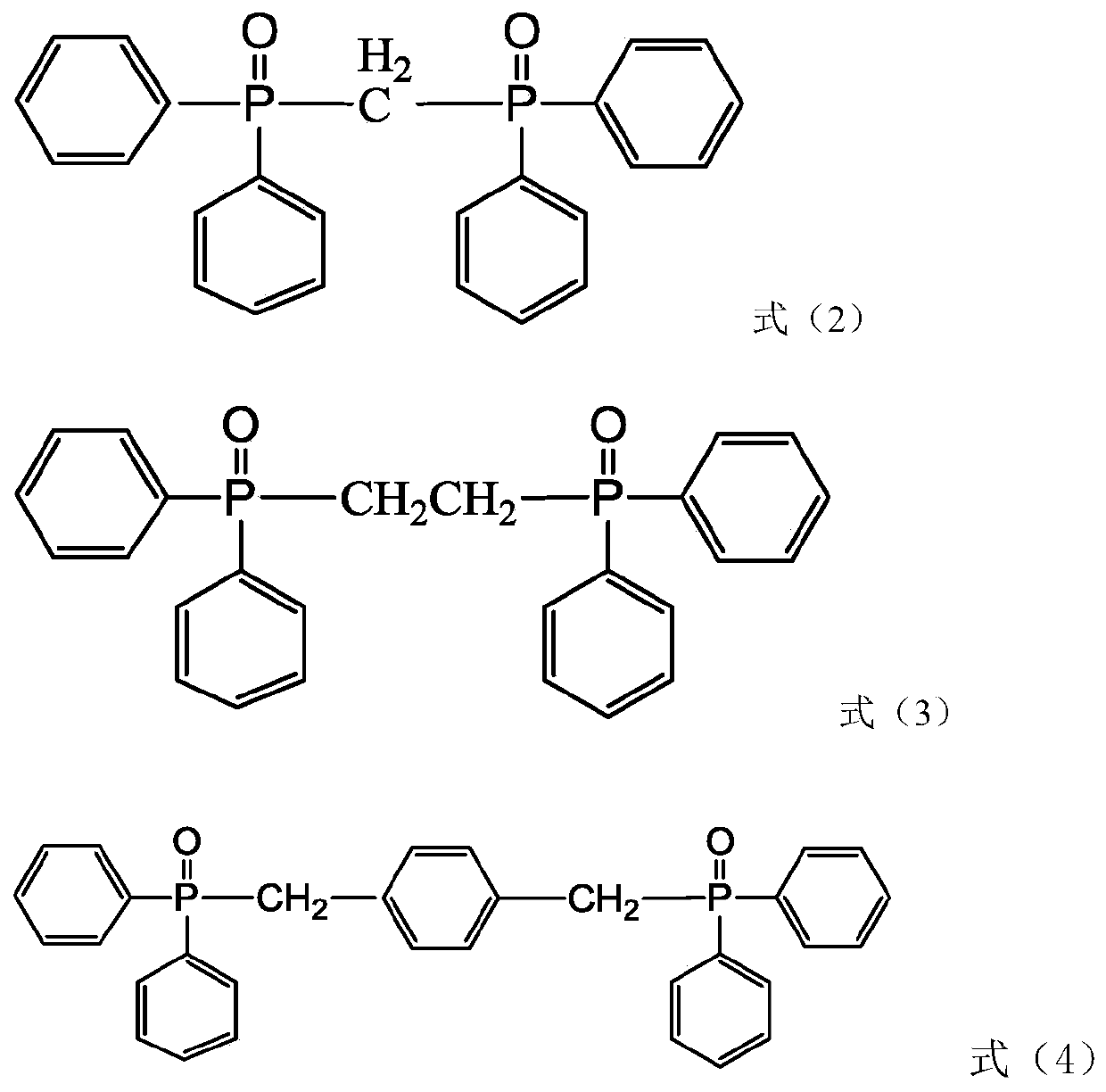

Method used

Image

Examples

Embodiment 1

[0038] Weigh 100 parts by mass of bisphenol A epoxy resin, then add 10 parts of flame retardant EDPO according to the formula, mix at 150°C for 3-5 minutes, and after it becomes transparent, add 30 parts of curing agent DDS, 0.2 parts of 2- Methylimidazole was stirred at 150°C for 5 minutes and placed in a vacuum drying oven to remove air bubbles. After being transparent, it was poured into a standard mold while it was still hot, cured at 130°C for 2 hours, and cured at 160°C for 2 hours. After demoulding, a light yellow flame-retardant transparent epoxy was obtained. Resin material.

Embodiment 2

[0040] Weigh 100 parts by mass of DCPD novolac epoxy resin, then add 10 parts of flame retardant EDPO according to the formula, mix at 150°C for 3-5 minutes, and after it becomes transparent, add 30 parts of curing agent DDS and 0.2 parts of 2-formaldehyde For imidazole, stir at 150°C for 5 minutes, put it in a vacuum drying oven to remove bubbles and make it transparent, pour it into a standard mold while it is hot, and then cure it at 130°C for 2 hours, and then cure it at 160°C for 2 hours. After demoulding, a light yellow flame-retardant transparent epoxy is obtained Resin material.

Embodiment 3

[0042] Weigh 100 parts by mass of bisphenol A epoxy resin, then add 10 parts of flame retardant PDPO according to the formula and heat up and mix for 3-5 minutes. After it becomes transparent, add 30 parts of curing agent DDS and 0.2 parts of 2-methylimidazole , Stir at 150°C for 5 minutes, put it in a vacuum drying oven to remove bubbles and make it transparent, pour it into a standard mold while it is hot, and then cure it at 130°C for 2 hours, and then cure it at 160°C for 2 hours. After demoulding, a light yellow flame-retardant transparent epoxy resin material is obtained. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com